When punching sheets, compression and tensile forces often cause sheet deformation. The integrated flattening considerably reduces sheet unevenness. In order to compensate for the stresses on the sheet and to produce an even sheet, the tool's die, along with the active die, presses the sheet against the stripper. The punching stroke is then carried out in the pre-stressed sheet with the same tool.

When the punching process is finished, the stresses have balanced each other out – the sheet remains flat. All of this in just one operation, along with a higher level of process reliability when further processing your parts.

Integrated flattening is performed using size 1 dies which are slightly convex. The specially coated stripper is concave, to enable the appropriate flattening of the sheet. TruTops supports you through rules in the programming.

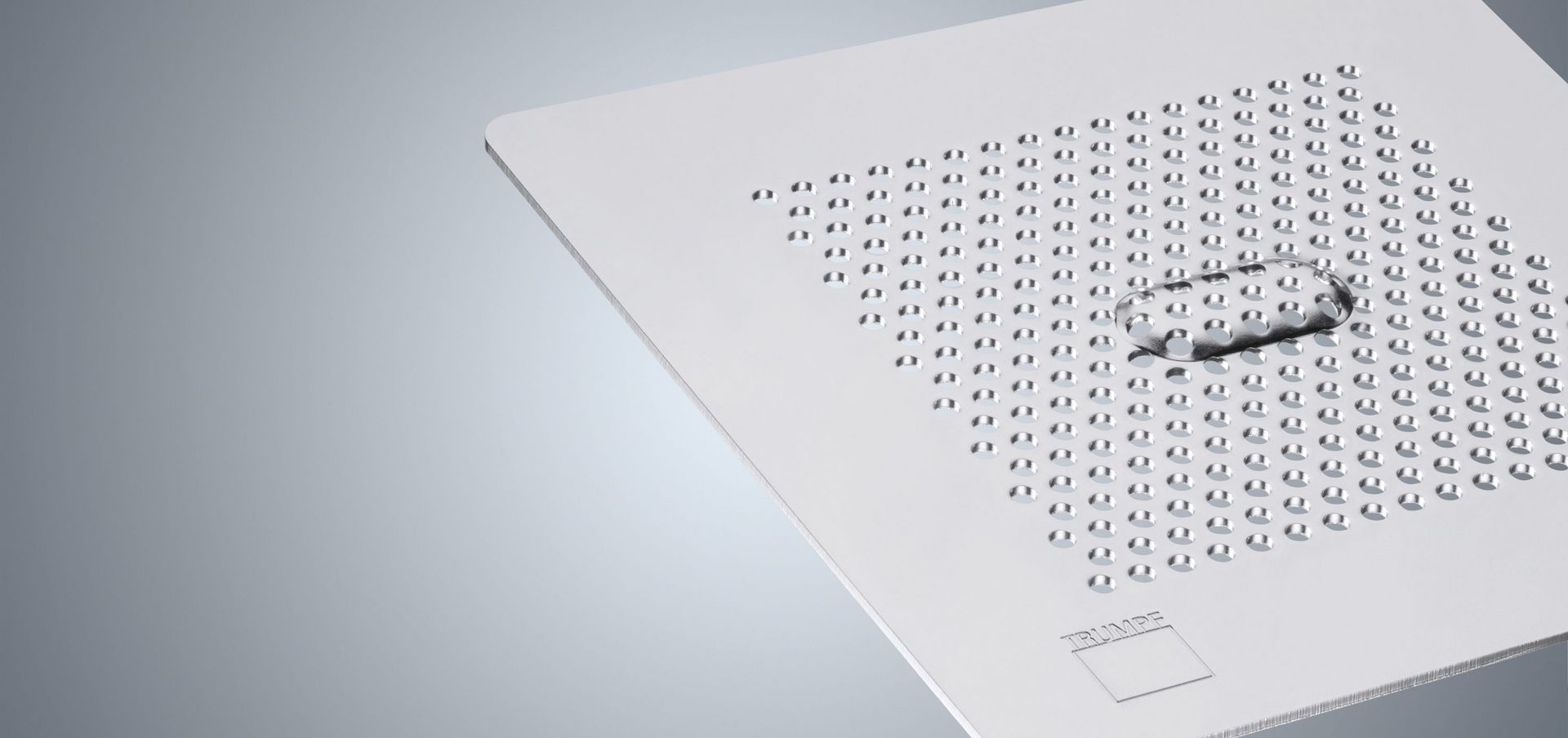

Simply flat sheets

With the cluster tool for integrated flattening and the corresponding machine function, you can smooth out unevenness in the sheet during the punching process. You can produce flat perforated sheets without post-processing. The function increases the part quality considerably, particularly for workpieces with a high degree of punching.

Optimal part quality

Guarantees distortion-free workpieces without post-processing

Considerable time savings

Considerably faster due to punching and flattening in just one operation

Flattening formed sheet parts

Even workpieces with formed sections can be flattened using the tool.

Added reliability

Flat sheets and workpieces ensure greater process reliability during further processing.

Individual flattening

The degree of flattening can be adjusted individually at the machine using TruTops.

Contact