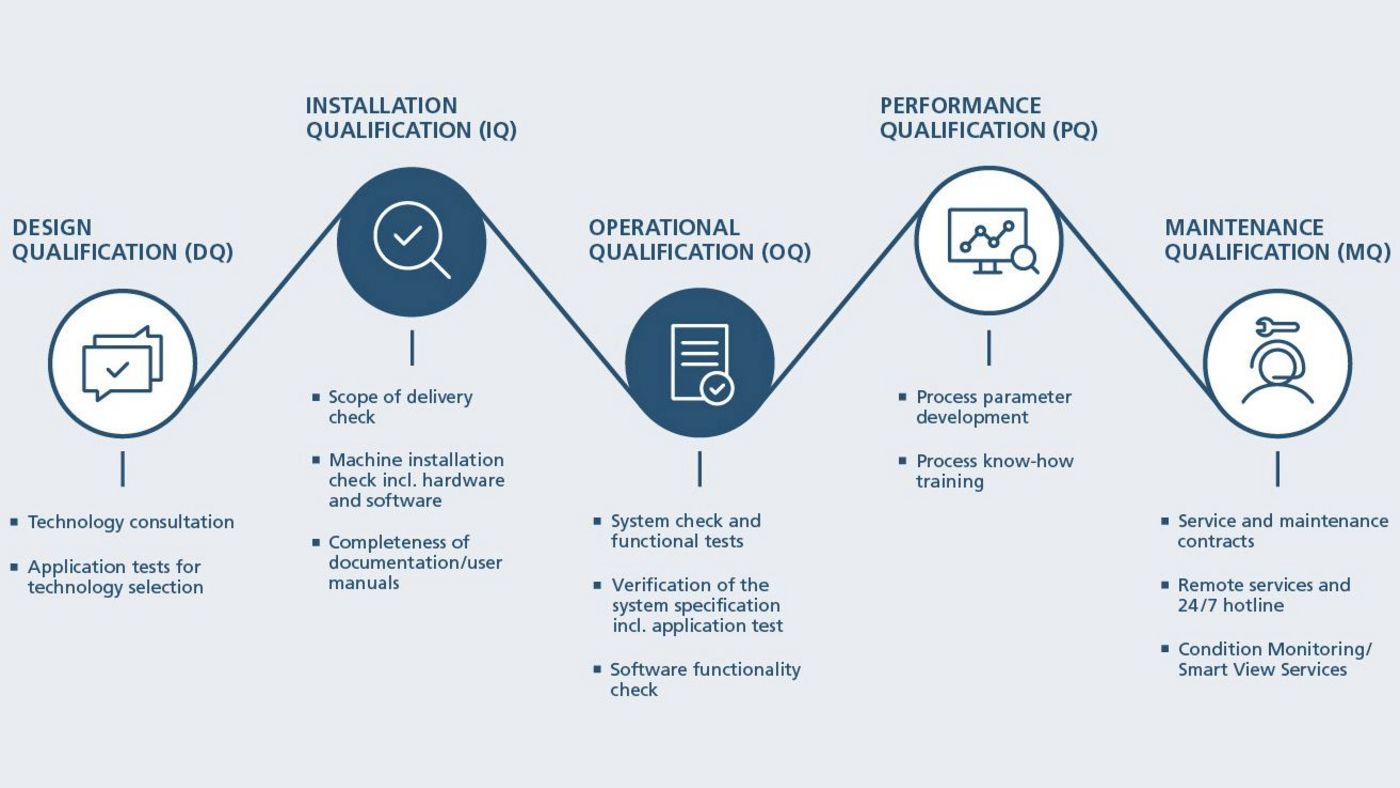

It can be quite challenging to have your laser system certified in regulated industries. Not with TRUMPF qualification experts who provide you time- and cost-saving support throughout the qualification process and constantly continue to develop your range. Our focus is on the particularly comprehensive standards and requirements from the medical technology and aviation and aerospace sectors. This way, our services are oriented primarily toward the requirements of the following standards and institutions: ISO/ASTM 52941 / 52942, ISO 13485, ISO 9100, FDA, NADCAP, and more.

Compliant installation and qualification of laser systems in regulated industries with TRUMPF expertise

You can count on our comprehensive tests, measurements, and detailed documentation when it comes to preparing your system for certification. We carry out application tests for feasibility and find qualified parameters together to ensure the corrosion resistance to certain materials, among other things.

Within the framework of TRUMPF IQ/OQ services, we take all critical aspects of the installation and function of your machine into consideration in a standardised process. The stability of the laser processing procedure is additionally supported by the TRUMPF PQ/MQ service.

As well as the time-efficient machine qualification, we support you with optimum integration into your digital production environment, for example, inclusion in your ERP system.

With our extended maintenance services you'll hold in-depth knowledge about the status of your system – every year.

Together with you, we will make sure that your system retains its certified condition, even after repairs.

We offer you the following services

Our customers say ...

We offer qualification support for the following systems*:

*The supported systems may vary depending on the country. Please contact us.