Standard product enhancements are machine options which can be integrated into your TRUMPF product without extensive adaptation work.

Would you like to implement new applications on existing TRUMPF machines, systems or lasers? Functional upgrades enable you to implement new customer requirements, work more profitably or increase your added value in a targeted manner.

With product enhancements, you can also react quickly to changes on the market with flexibility.

Specifically count on product enhancements to lower your costs and increase your profit.

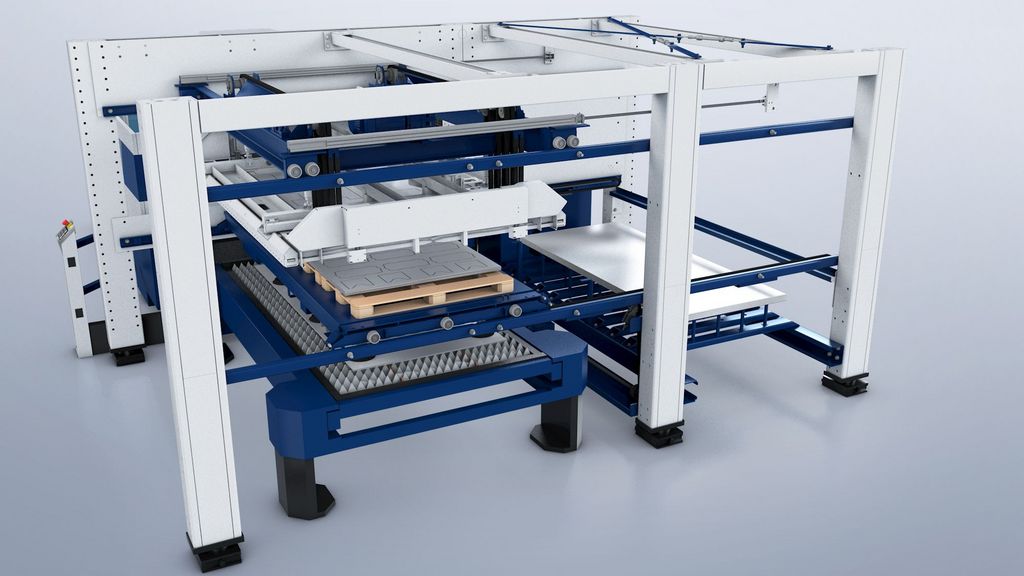

Reduce non-productive times and become more productive – through automation, for example.

Improve your process results by retrofitting innovative sensor systems.

Become more efficient, improve processes – increase your production's output with Product Enhancements

Tailored solutions

Do you have an idea or requirement that you cannot achieve with standard functions and existing automation solutions? With TRUMPF, you can quickly find a customised solution to expand the functions of your machines, lasers and laser systems.

Get in touch with us!