The right tricks allow you to design your parts more cost-effectively. The solution: reducing the number of single parts and process steps. The support bracket shown here originally consisted of three parts connected with four weld seams, plus separately cut threads. It was redesigned out of just one bending part – without welding. An additional bend even allows you to reduce the sheet thickness and form the threads directly on the punching machine.

Part optimisation

What potential is hidden within your parts? Find out in our workshops and seminars on part design. If you want to manufacture parts more profitably, produce new parts or enter new types of technology – the relevant specialist knowledge will help you trim your parts for success, while also saving money. Because cost-efficiently designed parts are the key to efficient manufacturing, require fewer process steps and reworking, and pave the way to networked production.

Keep materials, processing steps and costs to a minimum by designing your parts according to their function.

Part optimisation exercises on over 700 sample parts and your own components to ensure cost-effective part design.

Learn design rules for creative ideas and new solutions and train your eye to evaluate feasibility and economic efficiency.

Experience the application, design and manufacturing possibilities of sheet metal and tubes in over 1,000 training courses.

Sheet metal part design

Lighter, cheaper, or more functional: How would you like your parts? When sheet metal parts have a well-thought-out design, this allows your machines for laser cutting, punching, or bending to reach their full potential – while saving on materials, costs and effort.

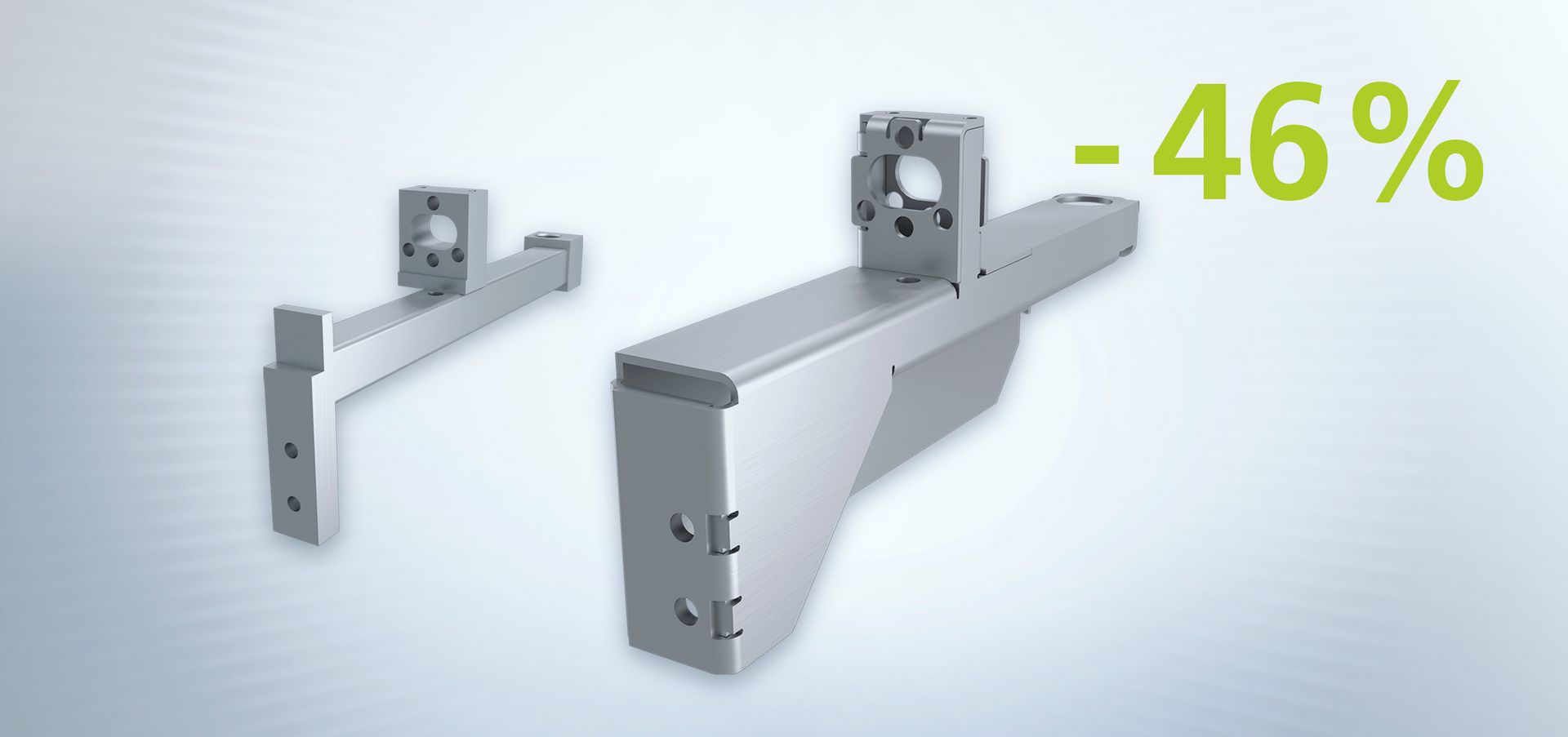

Example: optimised axis stop

The axis stop is conventionally produced out of a welded construction with a semi-finished product and milled parts. The many work steps are both time-consuming and cost-intensive. The new design made of two sheet parts reduces the number of parts and thus the joining processes and material usage.

1. Sawing

...all components to size.

2. Milling

... the contact surfaces, oblong holes and stepping.

3. Drilling

... all holes in the components.

4. Welding

... all four components.

5. Laser cutting

... allows for any desired geometries to be cut into sheet metal, and creates bores.

6. Tapping

... for more strength compared to cut threads.

7. Bending

... replaces welding and decreases the number of parts.

8. -46% in costs

... with the new design

Additional examples

Laser welding part design

A laser welding system allows you to manufacture for much less than with conventional welding, as long as you identify suitable parts and make these fit for laser welding. You can receive design and manufacturing-related tips and tricks from us.

Example: optimised cover

The conventional cover for electronic components such as electrical cabinets must be sealed and free of distortion. This is the crux with conventional TIG welding, as it results in distortion which must be corrected. The design which is suitable for laser welding replaces multiple work steps: both seam preparation and corrections are no longer necessary, as the lower heat input barely produces distortion.

1. Laser cutting

... including free corner cutting.

2. Bending

... ten bends.

3. Welding

Supplementary wire and weld seam thickness compensate for bending tolerances.

4. Grinding/polishing

... as manual work.

5. Laser cutting

... three parts from one sheet.

6. Bending

... eight bends.

7. Laser welding

... with minimal distortion and high optical quality.

8. -30% in costs

... with the design suitable for laser welding

Additional example

Fixture design for laser welding

Fixtures guarantee quality and more reliable processes during laser welding. However, what even experienced practitioners often don't know is that fixtures can be cheaper and more flexible when they are produced from single sheet metal and tube parts. Additionally, you can reduce production tolerances during welding. When are you going to make work easier for yourself?

Example: optimised fixture made of sheet metal for laser welding

A conventional fixture for laser welding is usually made from a solid milling block. Clamping fixtures made from sheet metal are economically superior to conventionally milled fixtures. This is because they lower manufacturing costs as well as weight. They also allow for additional functions to be integrated and increase heat dissipation.

1. Sawing

... the raw material of the rod to size.

2. Milling

... all reference surfaces and mounts as well as all through holes and threads.

3. Finishing

... by deburring and anodising.

4. Laser cutting

... any desired geometries and holes.

5. Assembling

... and welding single parts.

6. -17% in costs

... with the sheet metal design.

Tube part design

Tubes and profiles are used everywhere – from machine and system construction all the way to the furniture industry. Laser tube cutting saves entire process steps, which allows you to save money. Secure your share of the growing market for laser-cut tubes. You will learn exactly how this works with the appropriate advice.

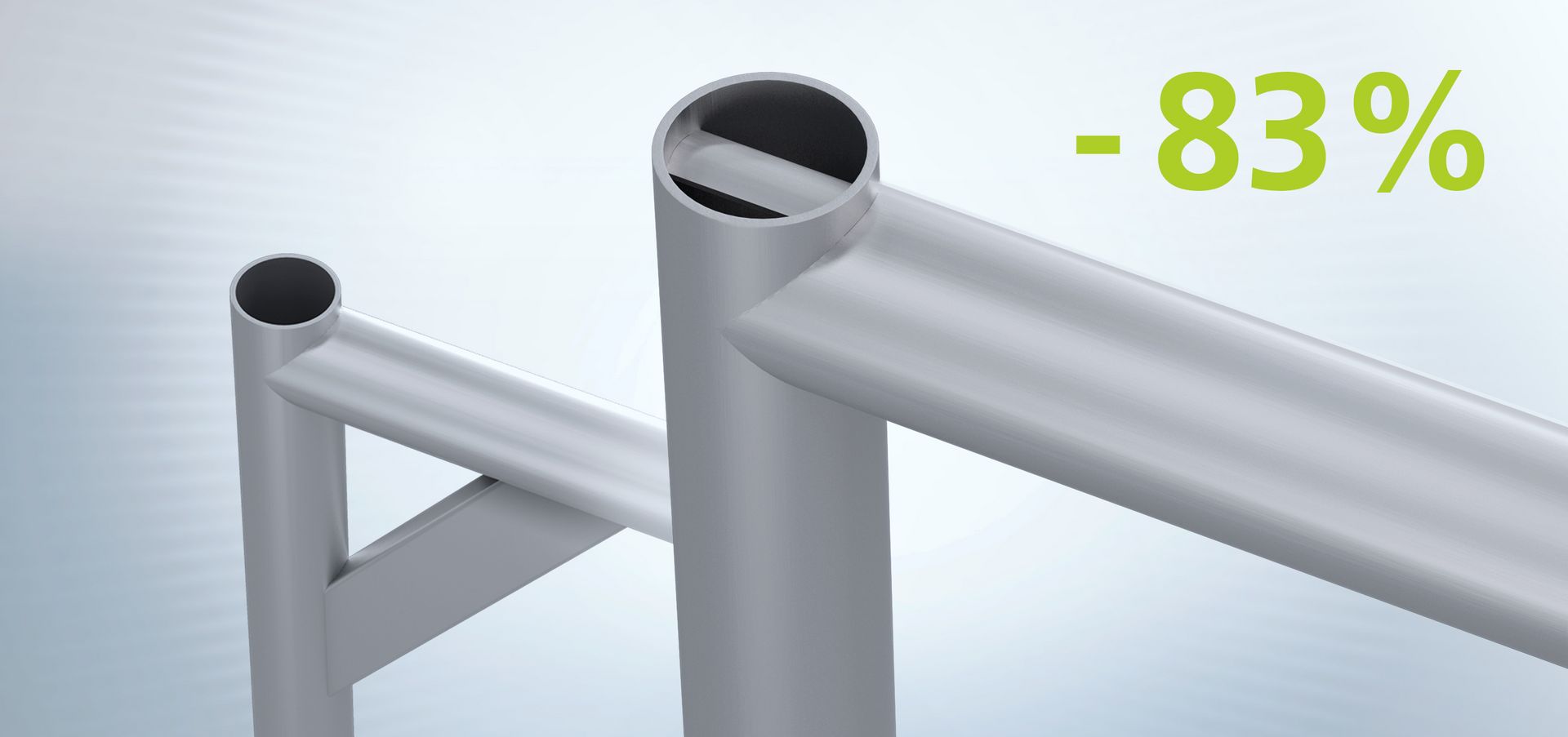

Example: optimised cantilever

In conventional manufacturing, three parts are adjusted to one another in individual process steps – which is time-consuming and logistically challenging. The cantilever is now cleverly manufactured from two identical tubes with identical shape and dimensions. Both parts are adjusted to one another on a laser tube-cutting machine and then connected together.

1. Sawing

... all components to size.

2. Milling

... the contact surfaces, oblong holes and stepping.

3. Welding

... all three components.

4. Deburring

... sawed and milled areas.

5. Laser tube cutting

... the entire assembly with just one clamping.

6. Assembling

... and welding the two single parts.

7. -83% in costs

...through clever connector design.

Additional example

Fixture design for arc welding

Would you like to increase the utilisation of your machines and produce welded assemblies in small lot sizes cost-effectively and with the same high quality? Then you should produce fixtures from sheet metal and laser-cut tubes in the future. It's easier and cheaper than you think.

Example: optimised fixture made of tubes for arc welding

The numerous milled parts in the conventional fixture are both time-consuming and cost-intensive. The costs of chipping manufacture are high and fits for pins and threads are necessary. The assembly must be welded when it is lying down. A tube plug-in design replaces the entire milling block. Its advantages: fewer parts, less effort. The vertical design of the fixture also makes it easily accessible for manual as well as automated arc welding, e.g. on a TruArc Weld 1000.

1. Sawing

... raw materials, various semi-finished products and dimensions.

2. Milling

... all surfaces which are to be bolted or joined.

3. Drilling

... precision fits, through holes and threads.

4. Laser tube cutting

... parts including all inner geometries and joining aids in pin form.

5. Assembling

... and welding the two single parts.

6. -80% in costs

... with flexible tube design.

View training calendar

Take a look at the TRUMPF digital learning platform! It is now even easier to gain know-how about TRUMPF technologies and machines. Book your training courses now and use the newfound knowledge to your competitive advantage.

The following training types are offered

Designers and product developers from a range of companies are welcome to participate in our seminars. You will gain insights into manufacturing expertise, tools and state of the art technology. You will work closely with other participants to establish design guidelines and put your new-found knowledge into practice by designing and optimising sample parts. This will help you to implement a more cost-effective and process-reliable production process.

Our bespoke customer workshops cover the same training content as our seminars. The unique aspect is that the participants in the workshop are an internal company group, and they learn through optimising their own parts during the workshop.

During direct interaction with the TRUMPF instructor, you will engage in an in-depth discussion of your specific assembly or fixture, with a strong emphasis on your individual needs and general circumstances. You will work together to enhance the design to ensure that production is both reliable and cost-effective.

Part optimisation - helping to make production more sustainable

90% of a product's carbon footprint is determined by the material processing. Our expert guidance helps you not only to reduce costs by minimising material usage but also to enhance sustainability within your manufacturing processes.

Optimate app provides real-time digital support

Which part are you starting with?

The first step is very easy: talk to us. Together we will come up with ideas for how you can take full advantage of the potential within your parts.