One of the first questions to be asked is often whether and, if so, how, induction technology can be used to simplify and optimise potential production steps. That is why we offer you a tailored solution consisting of several steps. This maximises transparency and certainty from the outset and enables you to first check the feasibility of the solution without needing to purchase a system directly. In this way, the requirements and process parameters are defined as the first step. We then take these as the basis for determining and preparing suitable analytical methods and performing a wide range of tests. The approach we take is as unique as your process.

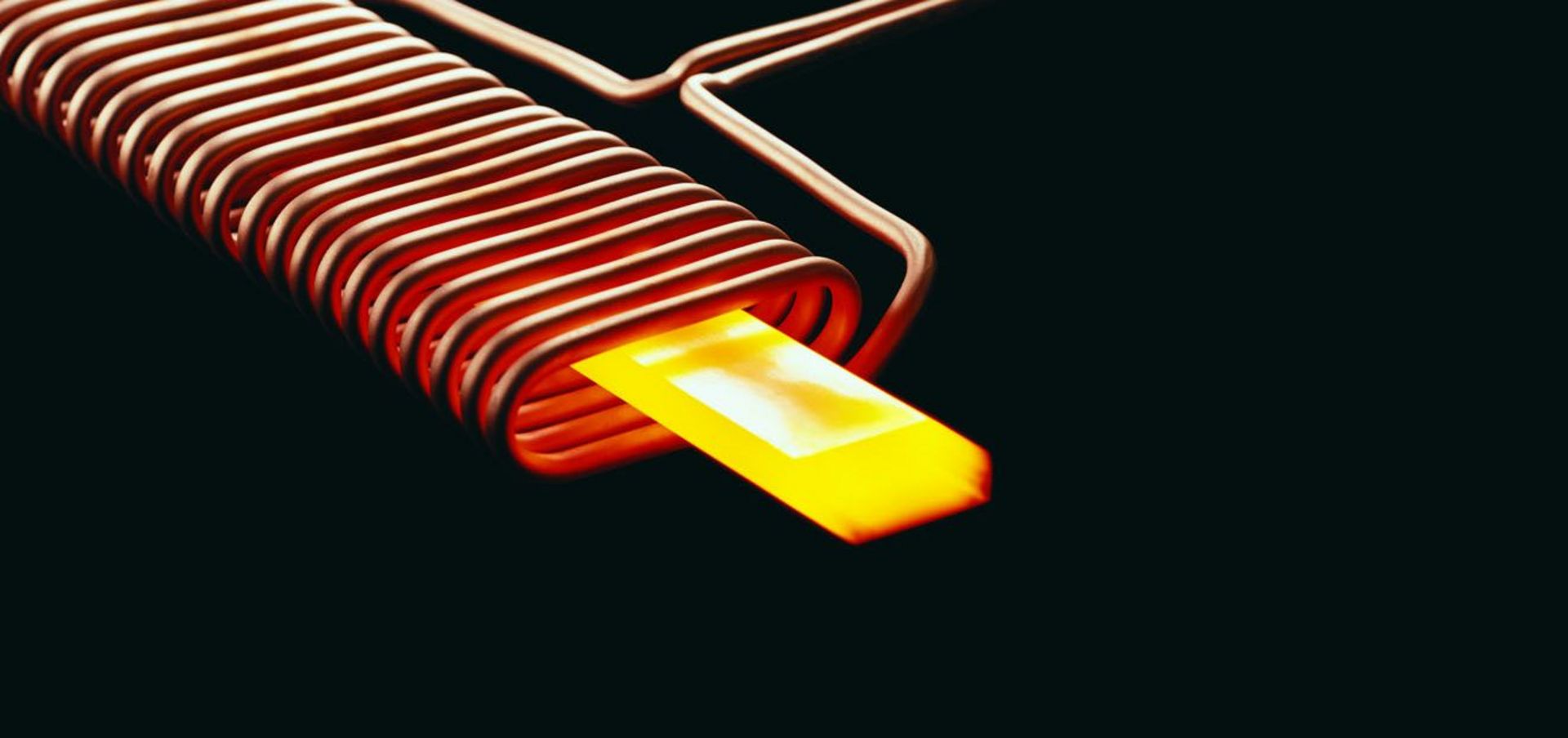

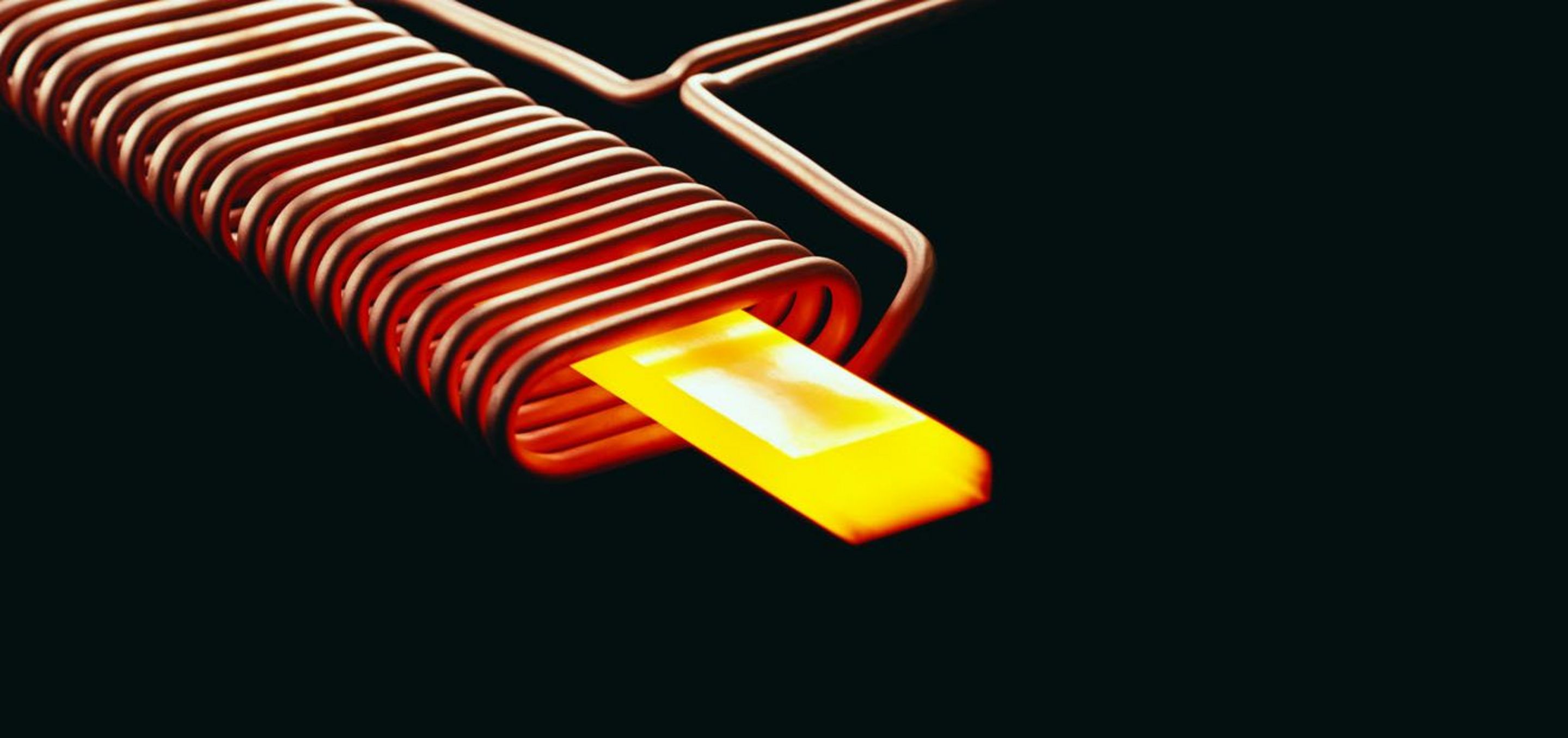

Due to the attractive combination of speed, resistance, control, and energy efficiency, the targeted use of induction heating offers major benefits in many production processes across a range of sectors. The potential areas of application and possibilities are practically unlimited. TRUMPF Hüttinger acts as an experienced partner for you in planning and developing efficient, customised heating processes. Regardless of how complex your requirements are, we will work together with you to develop the ideal solution. We will only be satisfied when we know that you are too.

Feasibility study with minimal investment expenditure

Greater efficiency and lower costs thanks to optimised heating process

Solutions which are tailored to your production setup

You can rely on our experienced engineers!