In many industrial processes today, natural gas-fueled flames are used to generate the process heat. In order to achieve certain temperature limits, the past international climate conferences have agreed to make CO2 -generating processes much more expensive worldwide. This way, in a few years the above-mentioned heating tasks will no longer justify the costs.

In many industrial heating processes, a fundamentally different heating method can be used (dielectric, resistive, inductive heating). In some other processes there is no real generic alternative to a "flame".

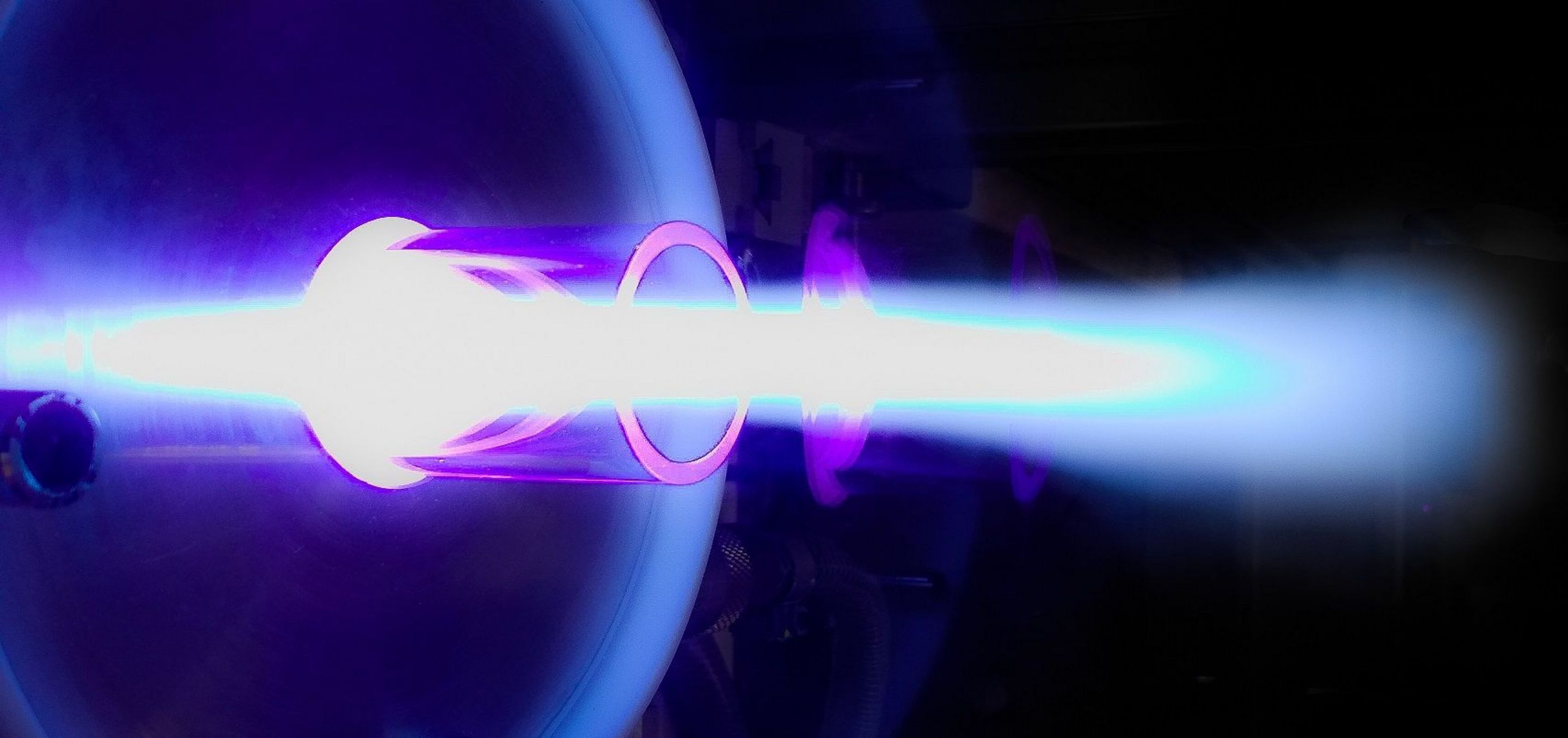

A plasma-based flame (plasma burner torch) can be a solution in this case. At atmospheric pressure, an assist gas (H2, CO2, N2, O2, argon, air,...) is streamed through a pipe arrangement (0.05 m - 1 m or more in diameter). This gas is excited in a special arrangement to form a plasma or plasma flame. This is conducted from the outside, and thus without contact, by means of medium-frequency - high-frequency inductive power input. An interesting aspect is that the above-mentioned assist gas can be "recovered", i.e., returned to the process as recycling. In fact, nothing "burns" in this process, despite the fact that the heat is generated in a flame.

TRUMPF Hüttinger is currently developing process power supplies and power couplings that will soon replace heat generation using natural gas flames, up to the megawatt range. These have a wide range of applications, for example, in metal production or metal recycling, and in the chemical and glass-producing industries.

Do you want to find out more? Please contact us: