Productive high-end machine

The TruMatic 7000 combines the advantages of punch and laser processing in a particularly cost-efficient way. The high-end punch laser machine meets high demands as regards part quality, productivity and flexibility. With the active die, you can produce scratch-free parts and also profit from the greatest level of flexibility when forming.

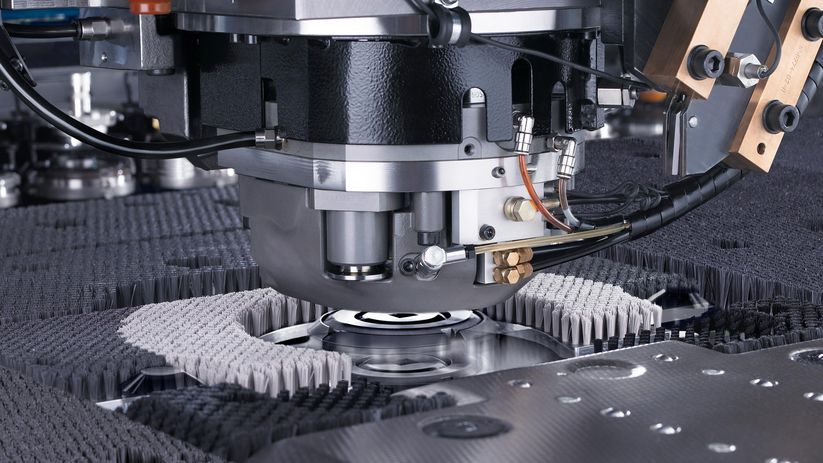

The active die provides you with scratch-free processing and new forming options due to the active forming stroke from below.

The CO2 laser guarantees high-precision cutting results through outstanding beam quality.

The additional axes provide a clear productivity gain – right up to extremely high levels of productivity.

The automatic nozzle changer removes the old nozzle for new orders, and inserts a new one, saving time in automated operation.

You can remove parts in a process reliable way via sensor-protected flaps.

With the SheetMaster, you can load, unload and sort parts in a process reliable and automated way.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- The dimensions are approximate; the dimensions specified in the installation plan are valid.