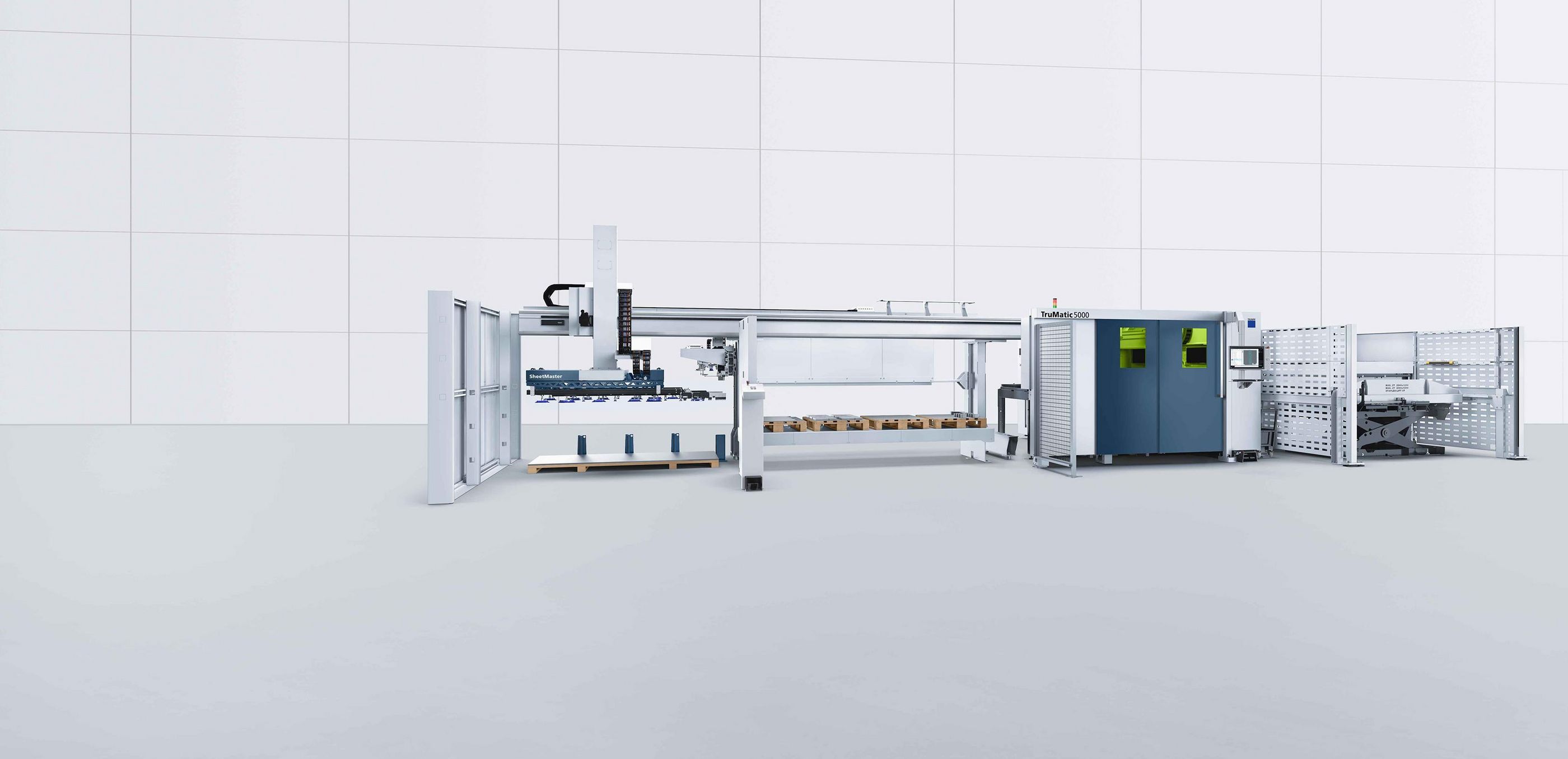

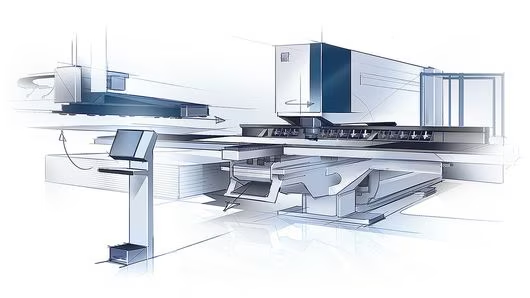

The ultra-productive punch laser production cell

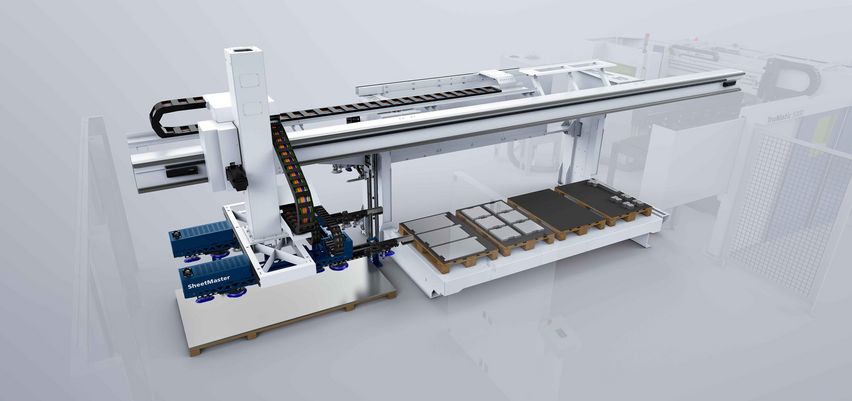

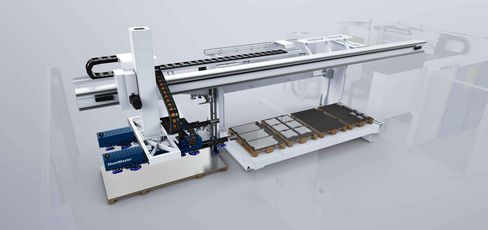

The TruMatic 5000 and the new generation of SheetMaster* automates the material flow in your punch laser production operation, from fast loading to unloading, palletization and sorting. With a laser power of 6 kW, the TruMatic 5000 sets new productivity standards on the market, while also excelling in terms of high energy efficiency. Nozzle changers, the pre-separation of metal sheets parallel to production, the integrated axis for enhanced flexibility and a range of individually controllable suction cups collectively enable you to achieve autonomous and efficient production.

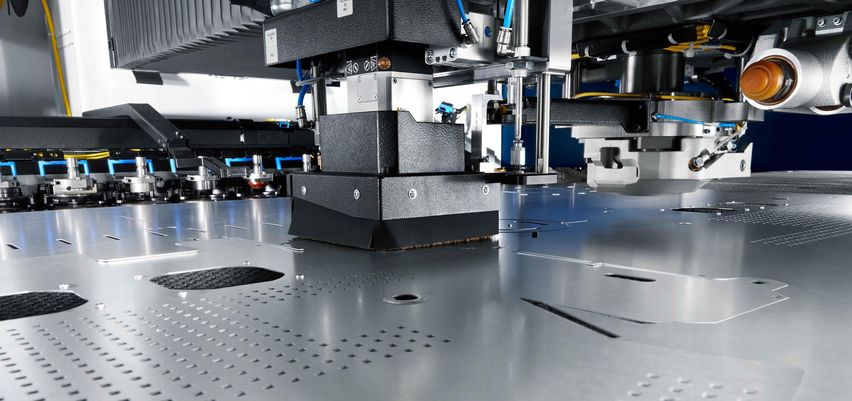

The TruMatic 5000's powerful 6 kW laser makes your punch laser production ultra-productive.

The automated punch laser system is ideal for multi-shift operation.

The descending die enables scratch-free punching and forming processes.

The ToolMaster changes tools fully automatically in the machine – for maximum process security.

In addition to standard materials, the laser can cut a wide variety of non-ferrous metals effectively and reliably.

The machine's solid-state laser and Delta Drive achieve a high level of efficiency and an excellent energy balance.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Without load carrier

- Expected to be possible from 2026 via additional package