Productive universal machine for punched and laser parts of the highest quality

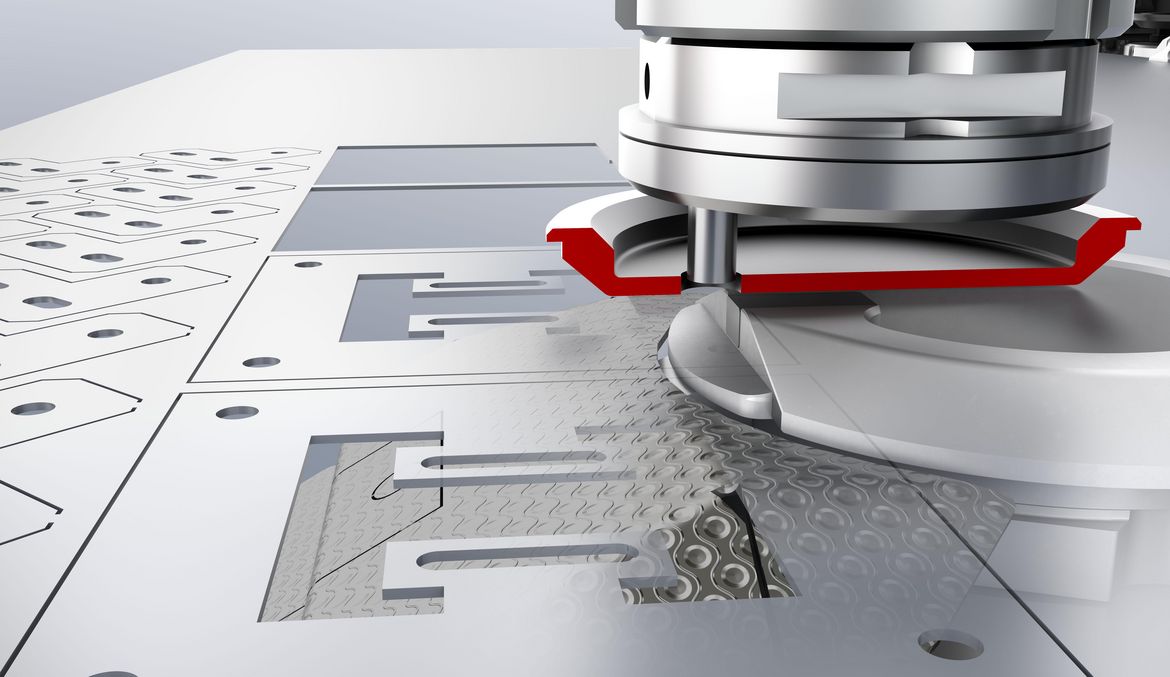

For all-rounders aiming to manufacture productively and yet economically: the compact TruMatic 3000 fiber combines the advantages of punching technology with high-quality laser cutting. Parts can be manufactured entirely on just one machine, thereby eliminating the follow-up processes. It achieves outstanding part quality thanks to the descending die and is easy to operate with the touchpoint HMI.

You can laser, form, punch, tap, emboss, mark, engrave and deburr with a TruMatic machine.

Scratch-free punching thanks to the descending die.

Removal and sorting solutions for small to large parts.

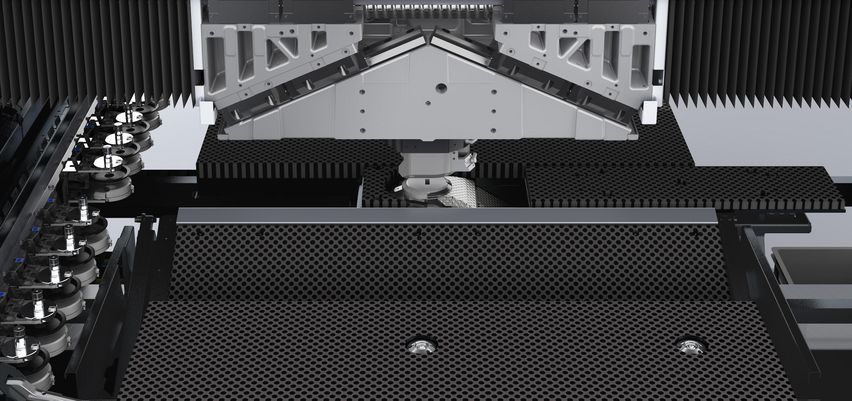

The Delta Drive brings more dynamic to the machine – and saves 25% of the installation area compared to a punch laser machine.

With the robust TruFiber solid-state laser, you can achieve high productivity even when cutting non-ferrous metals.

The dynamic Delta Drive requires 25% less installation surface and - in combination with the solid-state laser - 65% less energy than a punch laser machine with hydraulic drive.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.