One system, countless benefits

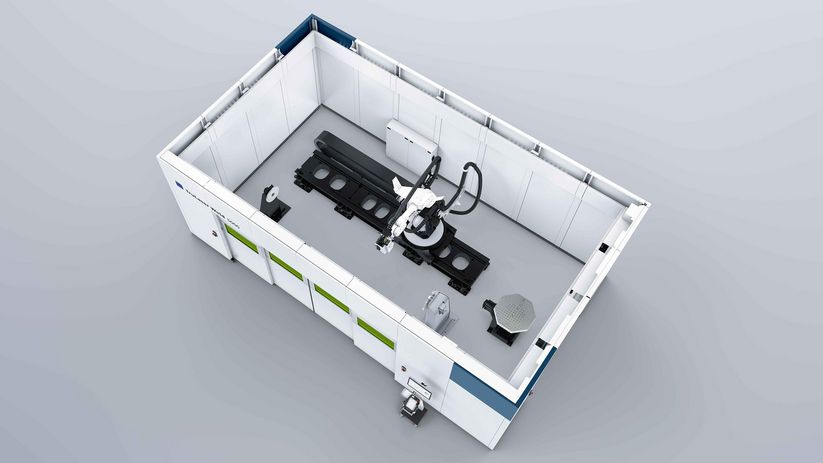

Robots, lasers, processing optics, enclosed protective housing and positioners – TruLaser Weld 5000 is a turn-key system for automated laser welding. You can flexibly weld deep and strong seams or beautifully rounded, smooth seams using one system. FusionLine also enables you to connect components with gaps. The versatile system can be precisely tailored to meet your needs with different component positioners.

Heat conduction welding, deep penetration welding or FusionLine – all on just one machine

Functions such as the rotatable control panel and the additional status monitor make your work easier.

The rotary module for shield gas guidance provides excellent parts accessibility

Different component positioners are available depending on the desired loading option.

With the simple TruTops Weld offline programming system

The TeachLine sensor system reliably detects the seam placement.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.