Integrated image processing optimises welding results and you can rely on getting consistently high quality parts and complete process documentation. Rejects are then reduced to a minimum.

Cost-effective and versatile 3D laser welding

3D laser welding

Are you looking for a compact, efficient and at the same time ergonomic 3D laser welding system for processing small assemblies such as sensors, rotationally symmetrical components and medical devices? The TruLaser Station 7000 is a compact and fully equipped, low-investment 3D laser welding system in the TRUMPF portfolio. It has a very broad range of applications thanks to a higher laser power of up to 2 W and higher flexibility. It has a small installation area but a large work area for integrating fixtures and processing larger components. An optional rotary table means large quantities can be processed much more productively than with comparable products.

The TruLaser Station 7000 rotary table equips you perfectly for highly productive series processing.

Benefit from maximum process reliability thanks to fully integrated image processing.

Thanks to optimised axis kinematics, larger assemblies can be processed on a small installation area.

Flexible weld seam geometries and high welding depths are easy with the powerful lasers.

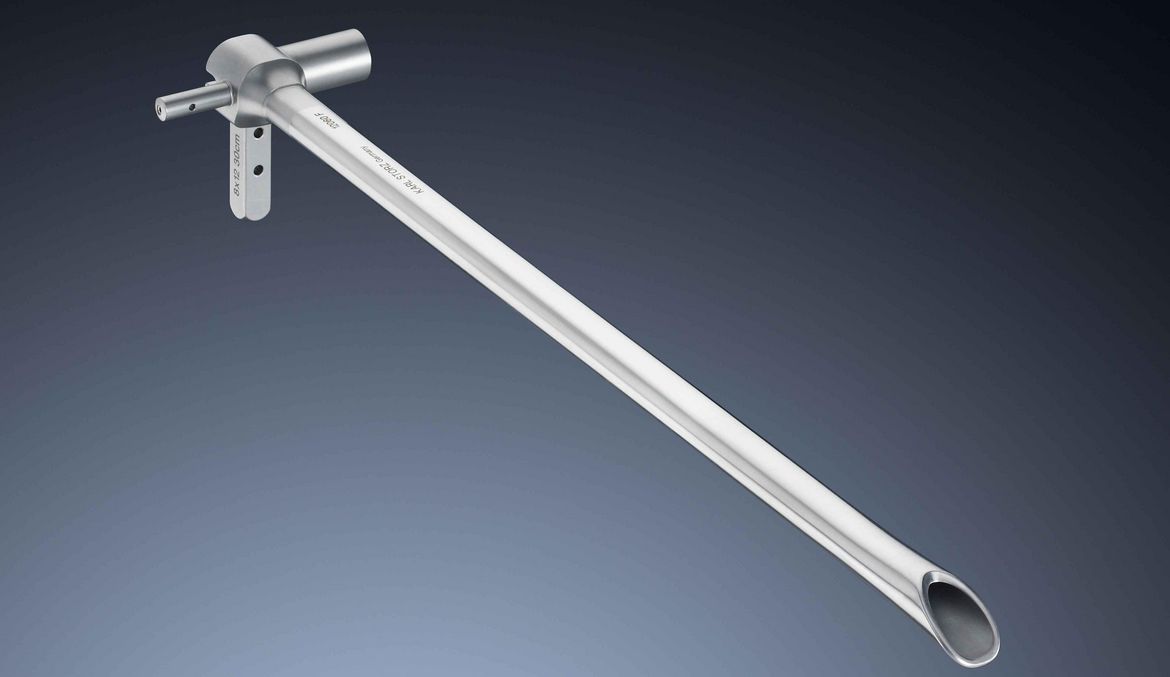

Welding of complex medical instruments

Nowhere is precision more important than in medical technology. With the TruLaser Station 7000, you get high-quality, reproducible weld seams without post-processing.

Direct Copper Bonds (DCB)

The TruDisk lasers with green wavelength can also weld thin materials with no impact on the base. For example, copper tracks can be contacted onto substrates using ribbons or wires, without damaging the underlying ceramic.

Sensors and valves

Heat conduction welding enables quick and easy joining of thin-walled components and visible edges can be produced without post-processing. This results in an overall faster production process.

Electrical components

Series production of micromotors and sophisticated electronic components requiring maximum quality can be produced on the TruLaser Station 7000.

Welding of complex medical instruments

Nowhere is precision more important than in medical technology. With the TruLaser Station 7000, you get high-quality, reproducible weld seams without post-processing, for example in the manufacturing of a bronchoscope.

Welding of complex 3D geometries

Maximum process reliability with VisionLine Detect and QDS interface for exporting machine and process data.

Smart Teach app

Smart Teach is an application for your PFO programmable focusing optics. It makes it easier to create and set up laser welding programs. The digital camera transmits the live image to the app. This enables convenient teaching directly at the component. If you want to create and teach in geometries, you can do this by way of intuitive gesture operation on a tablet PC.

TruTops PFO for scanner welding applications

The TruTops PFO offline software enables you to conveniently program your 2D and 3D laser processes: simply create the desired paths, edges or surfaces in the editor. Alternatively, you can load existing workpieces from CAD programs and program processing operations based on these.

Depending on the application you can choose from a wide range of solid-state lasers and select the perfect one for your needs. The TruLaser Station 7000 can be equipped with all fibre-guided TRUMPF solid-state lasers with laser powers up to 2000 W.

Numerous options make working with the TruLaser Station 7000 not only easier, but, due to reduced non-productive times, also noticeably quicker and therefore more productive.

BrightLine Weld enables virtually spatter-free laser welding. At the same time, productivity is increased and higher feed rates achieved while maintaining the same level of seam quality. The technology can also be used to optimise energy efficiency. Lower laser power is required to achieve the same welding depth.

At regular, individually set intervals, the TRUMPF CalibrationLine Power tool checks whether the laser power on the workpiece actually meets your specifications. This ensures consistent process conditions, so you can rely on constant and reproducible welding results.

Automation is easy with the TruLaser Station 7000. The 2-station rotary table enables simultaneous manufacture and set up. This is particularly recommended for high quantities. Loading and unloading of your parts by robot is also possible.

The intuitively operated image processing system VisionLine automatically detects geometric features on the component, such as joint gaps or edges. It corrects the NC processing program as required. This provides you with maximised process reliability, increased quality for your components, and savings in terms of time and costs.

The diverse modular optics kit, which has stood the test of time, harmonises perfectly with the TruLaser Station 7000 thanks to its compact design.

Focusing optics

Whether for welding, cutting, ablating, heating up or drilling: with robust focusing optics from TRUMPF you can attain high-quality process results.

Programmable focusing optics

The ideal optics for remote processing

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.