You can operate the TruLaser Cell 3000 intuitively and easily with the interface developed by TRUMPF on the basis of the Siemens 840D solutionline. During cutting, you can use the cutting parameters already stored on the control system and optimised by TRUMPF for the most common laser types, material types and material thicknesses.

Your system for flexible laser processing of small and medium-sized components

2D laser cutting | 3D laser cutting | laser welding | laser metal deposition

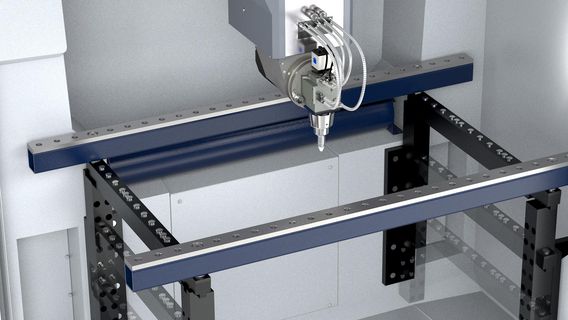

With the compact and high-precision 5-axis laser machine TruLaser Cell 3000 you can weld and cut in two or three dimensions. In addition, the 3D laser machine is also suitable for laser metal deposition (LMD). From prototypes to large-scale series production with extensive automation, this multi-talented machine displays its superiority across the board. This applies particularly to cost-effective laser processing of small to medium-sized components with top quality.

Welding, cutting and LMD through simple and fast process adapter changes

For higher quantities the machine can be automated very simply in line with the customer's specific requirements.

Tailor-made fixture concepts with sophisticated clamping systems and sensor systems from a single source.

Easy to retrofit or upgrade with a large number of options and processing optics.

Maximum repeatability across the entire 3D working area

Use the full work area for large installations and comprehensive automation systems.

Deep welding

The 3D laser machine TruLaser Cell 3000 is suitable for deep welding, for which very high power density of around 1 megawatt per square centimetre is required. Deep welding offers high efficiency and high welding speeds. Thanks to the high speed, the heat-affected zone is small and any distortion is minimal. This process is used for applications requiring high welding depths or in cases where multiple material layers are to be welded at the same time. A typical example in which this process is used is the laser welding of an automotive differential gear.

Laser-welded control gear

If a component is worn as a result of high temperatures, pressure, abrasion or moisture, it is not always necessary to replace the entire component. Laser metal deposition is a fast and cost-effective alternative to manufacturing a new part.

Laser cutting and welding

The TruLaser Cell 3000 is used both to cut slots and to perform welding on the electromagnetic water pump coupling. The fast process adapter change means that the TruLaser Cell 3000 is extremely flexible in terms of processes.

Laser-cut stator plates

Laser cutting makes almost any contour shape possible – even intricate and complex ones – without the need for tool changes. The edges are smooth and burr-free, so there is no need for post-processing. Thanks to the small size of the heat-affected zone, there is also barely any distortion. Laser cutting is used particularly on metals: steels, aluminium and alloys.

Operating table

Components such as the head plate of an operating table used to be milled in a lengthy and complex process. With the aid of the TruLaser Cell 3000, the component can now be welded together from two individual laser-cut components, offering up cost savings in the process.

Laser-cut kitchen knives

Kitchen knives used to be stamped. This led to high tool wear and high tool costs, and whenever the contour was changed the tool needed to be changed. The result of this was extensive non-productive time and idle time. Today, lasers are a universal, wear-free tool that bring significant reductions in terms of cost and time. If the contour is changed, e.g. to a different knife geometry, then all that needs to be done is to change the program. In addition, there is no tool wear.

Heat protection sheet

Using the 3D laser processing of the TruLaser Cell 3000, heat protection sheets for exhaust gas systems can be laser cut, for example. Thanks to the precise light from the tool, neat edges are produced and there is no heat distortion.

|

TruLaser Cell 3000

|

|

|---|---|

| Axis travel range | |

| X axis travel range | 800 mm |

| Y axis travel range | 600 mm |

| Z axis travel range | 400 mm |

| Maximum axis speeds | |

| Maximum axis speed, axially parallel in X | 50 m/min |

| Maximum axis speed, axially parallel in Y | 50 m/min |

| Maximum axis speed, axially parallel in Z | 50 m/min |

| Maximum axis speed, simultaneous | 85 m/min |

| Maximum axis speed of B axis | 120 1/min |

| Maximum axis accelerations | |

| Maximum axis acceleration, axially parallel in X | 10 m/s2 |

| Maximum axis acceleration, axially parallel in Y | 10 m/s2 |

| Maximum axis acceleration, axially parallel in Z | 10 m/s2 |

| Maximum axis acceleration, simultaneous | 17 m/s2 |

| Maximum axis acceleration of B axis | 130 rad/s2 |

| Positioning accuracy | |

| Positioning accuracy of linear axes (X, Y, Z) | 0.015 mm |

| Positioning accuracy of rotary axes (B) | 0.02 ° |

| Laser | |

| Maximum laser power | 8000 W |

| Available lasers | TruDisk, TruFiber, TruDiode |

The technical data of all product versions as a download.

TruTops Cell Basic

TruTops Cell Basic enables you to edit the cutting program directly at the machine. You no longer have to make changes in the NC program manually, meaning your processes are faster. All the changes you make using TruTops Cell Basic are visualised online and shown on the machine monitor.

TruTops Cell

TruTops Cell is an offline programming system for 3D laser processing. With this system you can create programs parallel to production, i.e. while production is running on the machine. TruTops Cell works with a large amount of 3D CAD data and includes the entire technological knowledge of TRUMPF. Important simulations such as collision checks or path optimisation are performed directly in the programming system. The software is compatible with all TRUMPF 3D machines and machining processes.

TruTops Boost

With TruTops Boost you can get the best out of your TruLaser Cell 3000 for 2D processing. Automated processes and wizards make day-to-day working with TruTops simple and efficient. The system autonomously generates, for example, looping or roundings on corners, and generates piercing points and approach and return paths. The parts that are to be cut are positioned by the software on the sheet in such a way that it is used in the best possible way. In the process, the TruTops Boost means that the laser machine automatically uses suitable parameters. Interfaces to leading CAD systems allow parts drawings to be quickly imported. However, with an integrated design module you can also create drawings yourself in no time at all.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

Depending on the task, select the correct laser for your application. The TruLaser Cell 3000 can be equipped with many fibre-guided TRUMPF solid-state lasers with a laser power of up to 8 kW. Higher laser power performance is available on request.

Numerous options make working with the TruLaser Cell 3000 not only easier, but, due to reduced non-productive times, also noticeably quicker and therefore more productive.

The rotational changer enables loading and unloading parallel to production at quantities above 100,000 pieces/a. The resulting two-station operation leads to high-yielding production. cycle times are shortened and non-productive times are reduced.

The intuitively operated image processing system VisionLine automatically detects geometric features on the component, such as joint gaps or edges. It corrects the NC processing program as required. This provides you with maximised process reliability, increased quality for your components, and savings in terms of time and costs.

With the additional workpiece axis (positioning axis in Z direction, 300 mm stroke) you can also process large 3D components, which can be up to 250% larger. The maximum 3D component size is increased as a result to a diameter of 600 x 520 mm. This allows you to make the best possible use of the work area and provides maximum flexibility for your production.

With the ergonomic teach panel you can program quickly and intuitively directly on the workpiece. The axes are precisely actuated via the 6D mouse. In the process, the integrated display will visualise all pending actions for you, and due to the utility programs you can create the tool path safely and quickly. In the process, the integrated display will visualise all pending actions for you, and thanks to the utility programs you can create the tool path safely and quickly.

The variable clamping system of the TruLaser Cell 3000 allows you to take full advantage of all of the options of a unique and flexible workspace management system. The hole matrix system helps you to achieve reproducible fixture set ups. Not only can you easily adjust the working height to suit your own requirements and the processing task in hand, but for applications with large space requirements you can remove the clamping system quickly and easily.

For loading and unloading via the side you can equip the TruLaser Cell 3000 with automatic side lifting doors. This allows the unit to be connected to transfer systems or for components to be loaded via a robot. The short opening and closing times ensure that non-productive time is minimised, thus maximising productivity in automated working environments.

The Central Link is an interface package with which you can network your machinery and use Industry 4.0 applications. The communication standard OPC UA enables you to transport machine data, such as control variables, measured values or parameters, and to describe them in machine-readable form.

Benefit from virtually spatter-free laser welding and top welding seam quality with the BrightLine Weld option. You have the choice – increase your productivity considerably due to significantly increased feed rates, or reduce your energy costs by up to 40%. In doing so, you can reduce your machine downtimes and operating costs, as post-processing is reduced.

There are various reasons as to why cutting slugs remain in the finished part. With the ObserveLine Comfort optical measuring process, you can detect this error quickly since this option checks every contour for a complete cut. ObserveLine Comfort has several advantages compared to measurement using distance regulation. The process reduces the measuring time and even smaller bore hole diameters and angled punching slugs can be measured.

At regular, individually set intervals, the TRUMPF CalibrationLine Power tool checks whether the laser power on the workpiece actually meets your specifications. This ensures consistent process conditions, so you can rely on constant and reproducible welding results.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

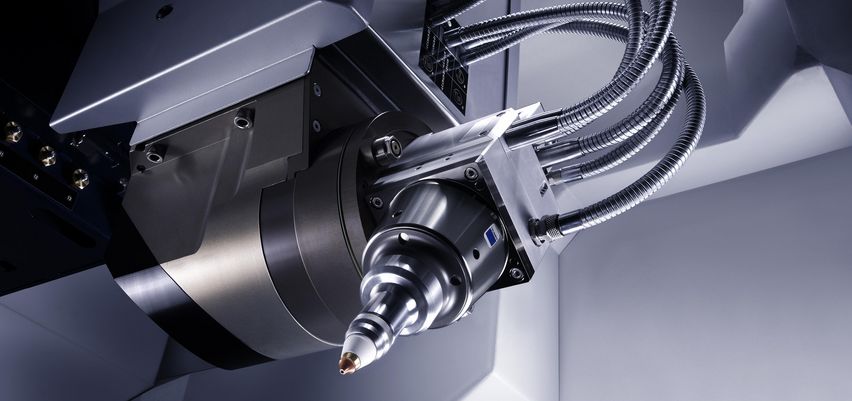

Focusing optics adapt the properties of the laser beam to the relevant task. The diverse modular optics kit has proven itself over years of use and is a perfect match for the TruLaser Cell 3000 thanks to its compact design.

Focusing optics

Whether for welding, cutting, ablating, heating up or drilling: with robust focusing optics from TRUMPF you can attain high-quality process results.

Programmable focusing optics

The ideal optics for remote processing

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.