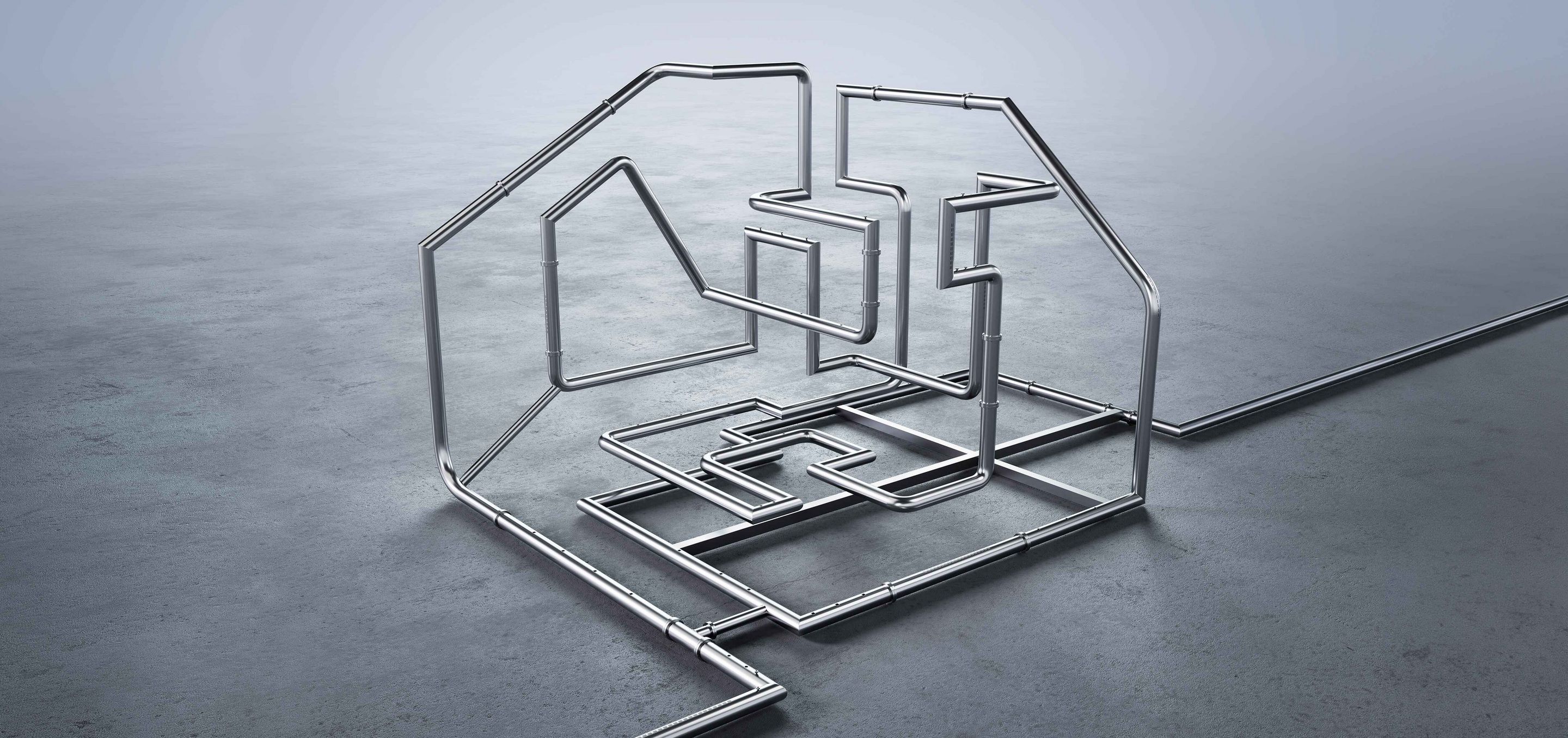

Tubes and profiles allow you to give shape to visions. For example, in vehicle frames, in furniture and lamps, in mechanical and plant engineering. A fully automated tube processing chain helps you to counter skills shortages and save money, and to tap into new business areas. TRUMPF provides all-encompassing solutions to fulfil your every requirement. In every scenario. When do you opt for unlimited possibilities from a single source?

The challenges of tube processing

What would be your ideal process chain for tube processing?

Increased security through seamless support along the entire process chain

The process chain for tube processing consists of storage, processing and welding. It can be automated precisely to suit your requirements. When fully automated, the process chain comprises up to 7 steps: storage, loading, laser tube cutting, unloading and sorting, tube bending, 3D laser cutting and welding. Our software and service solutions simplify the process. Alternatively, you can partially automate the process steps. The choice is yours – work with us to design the perfect process chain for your needs.

Overview of the process steps

1. Storage

The right storage solution for your raw materials and more storage space. The STOPA store and our Oseon production control system allow you to structure your warehouse and reduce search times.

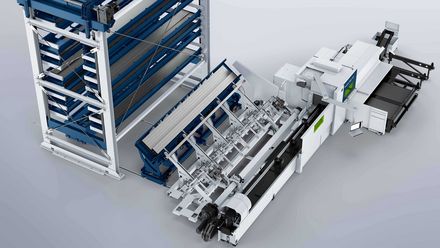

Find out more2. Automated loading

Load your laser tube-cutting machine fully automatically – the machine requests raw material via an interface and is loaded directly from the storage cassette.

Find out more3. Laser tube cutting

Customise complex contours and innovative tube designs with an economical, efficient and flexible technology that avoids rework and errors.

Find out more4. Automated unloading and sorting

Unload and sort automatically via the unloading automation interface with longitudinal conveyor belt. This reduces operator involvement as well as cutting out errors and saving money.

Find out more5. Tube bending

Highly efficient and precise CNC tube bending technology reduces component costs and avoids the need for welding and soldering work. We place our trust in transfluid® as a partner for this work.

Find out more6. 3D laser cutting

A TruLaser Cell system allows you to create complex geometries in bent tubes, both in bending zones and for final trimming.

Find out more7. Welding

Automated arc welding allows you to join components productively and with process reliability. Automated laser welding also saves you time and money.

Find out moreWhat visions are you aiming to achieve?

We provide full support with setting up your production solution for tube processing – arrange a no-obligation consultation now.

Watch the live talk!

Get access to our live talk – "The Future of Manufacturing: Boosting Productivity in Laser Tube Cutting"

Learn how laser tube cutting and automated laser tube cutting can transform your tube processing. Gain valuable insights into the tube process chain and learn about the advantages of innovative tube designs. Discover how automation concepts boost efficiency and productivity while setting new standards.

Would you like to discover how laser tube cutting can transform your tube processing?

Welcome back!

We are unlocking access to exclusive content for you!

We are currently reviewing your data...

Just one more step to gain access!

Many thanks for your interest in our exclusive content. Please open your inbox and confirm your address. Then you'll receive full access. Please check your spam folder as well.

Access not possible

Unfortunately, your registration for our exclusive content was not successful. Please contact us at info@trumpf.com or use the contact form.

Unfortunately, an error has occurred. Please try again later.

Modules for your fully automated production solution for tube processing

We provide the ideal components for each process step from a single source, either fully automated or a combination of automated and manual components. In other words, your solution can range from a single stand-alone machine to a fully automated system – fully customised to suit your requirements. You also have access to the right software and services.

Master new challenges

The benefits of a fully automated production solution for tube processing

When using automated processes, you need fewer qualified specialists.

Reduce the risk of errors and increase productivity and efficiency using automated processes.

Reduce cost pressure with strategic purchasing and shorter throughput times.

Counter a lack of space with vertical storage and optimised space utilisation.

Our solution partners

What visions are you aiming to achieve?

We provide full support with setting up your production solution for tube processing – arrange a no-obligation consultation now.