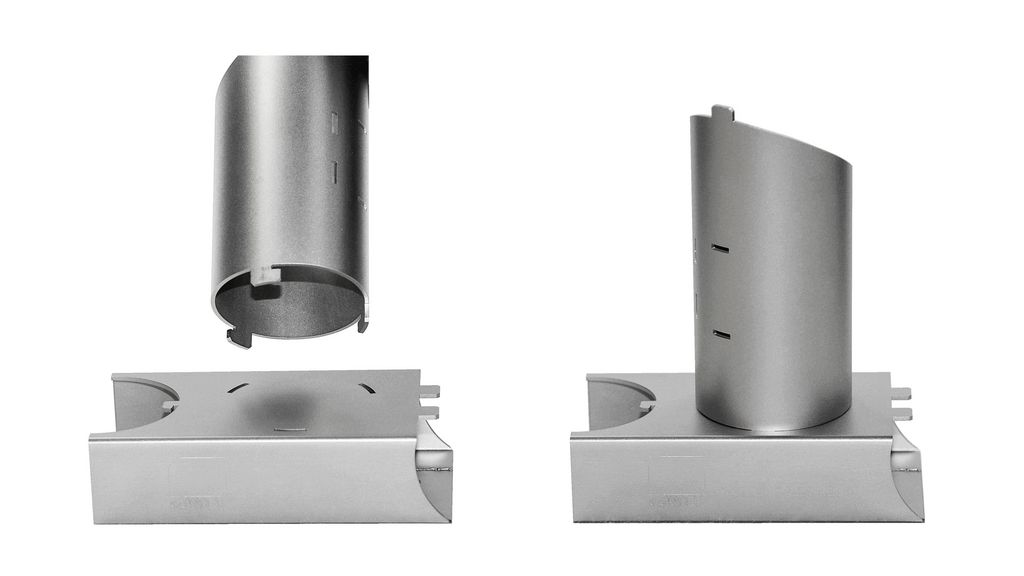

Using positioning, you can easily establish a connection between the flat material and the tube. This allows you to weld quickly and assemble accurately thanks to an assignment coding system.

Be a cut above the rest. Process tubes using lasers

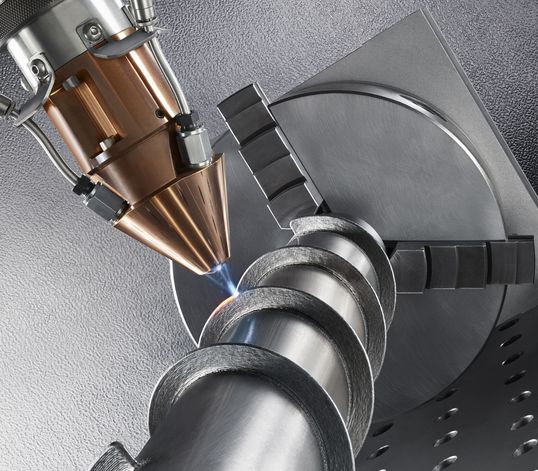

There is something magical about every new beginning. In the case of laser tube cutting, it is the high-precision tool – the laser. You can even cut complex contours, wall thicknesses up to 10 mm, or materials like mild steel, stainless steel and aluminium with a diameter of up to 254 mm effortlessly using the laser. In addition to a variety of materials and shapes, laser tube cutting offers even more – you can produce increasingly small lot sizes quickly and cost efficiently.

This is what our customers say

"The TruLaser Tube 7000 fiber is a complete all-rounder. The setup outlay when loading is minimal. Finished parts can be unloaded easily. The machine's user interface has a very clear structure. I was able to start producing quickly and reliably after just a short period of time."

"Word hasn't yet spread about many of the advantages of laser tube cutting. It doesn't just save us and our customers time and money, but also allows innovative tube designs, which we can now use to produce complete assemblies."

"Our productivity has increased by 30 per cent due to the new machine. The machine works very precisely. It has allowed us to reduce costly secondary processes significantly. Some old systems have even been made obsolete."

Technical advantage up. Part costs down

You can save a considerable 49% in time and 31% in part costs on our example part with a bend connection using laser tube cutting. At the same time, you can also make your processes and organisation simpler. Compared to conventional sawing, drilling and milling, you can also reduce downstream work steps such as deburring, welding or assembly. In just one operation, you can cut complex contours, form threads and cut tubes to length.

A comparison of laser tube cutting and conventional production

Become a pioneer in thinking outside the box

Cutting tubes and profiles using lasers opens up completely new avenues in design which were previously impossible using conventional processes. Free your design spirit and excite your customers with amazing design variants.

Would you like to hit the ground running right away?

Get experienced product experts from TRUMPF on your side. Regardless of whether you already have experience with conventional tube processing or want to tap into completely new business areas – we will support your project.

Whether in small villages or big cities, tubes are used everywhere. Designs made from tubes and profiles are ubiquitous

Tubes are a fixture of our every day lives:

From robust frame constructions for buses and agricultural machinery, delicate designer furniture and lamps to complex systems made from tubes in mechanical engineering and system construction – you can find tube designs that have been processed using lasers everywhere. No wonder – because there are few tools that can be used with such flexibility and offer so much contour freedom. Innovative products made from laser-cut tubes are already being used successfully – in the furniture industry, construction industry, automotive industry, commercial vehicles and transport, mechanical engineering, system construction, the agricultural sector, the fitness industry and in air-conditioning and energy technology.

This is what our experts say

The origin of TruLaser Tube machines

The Swabian Jura in Germany is where everything comes together. It is a holiday region that is affectionately sometimes also called the "Blue Belt". TRUMPF's impressive vertical range of manufacturing is tangible here. This is because all the components needed to build a laser tube cutting machine reach final assembly here. In this hustle and bustle, trucks deliver parts from surrounding sites, day in, day out. These parts are needed to be able to finally deliver the finished machine.

May we present your future tools for laser tube cutting

Everything from a single source – only from TRUMPF

By starting out with laser tube processing, you are setting a clear course for success in the long term. For this purpose, choose the complete package from the global market leader in laser technology. With a perfectly coordinated, constantly available production system, you will enjoy cutting with your machine for years to come.

We will accompany you on your path into networked production

Real success stories. Real people. Real tube solutions.

How have others done it? Find out more about our customers' success stories. They are some of the pioneers in their industries and often use completely new design options to manufacture their parts even more efficiently.

Tubes prefer TRUMPF – your expert in the world of tubes

Benefit from our decades of expertise in tube processing. As your partner, we will support you in all upstream and downstream processes.

Contact

Get in touch with us – our experts are by your side as a strong and skilled partner.