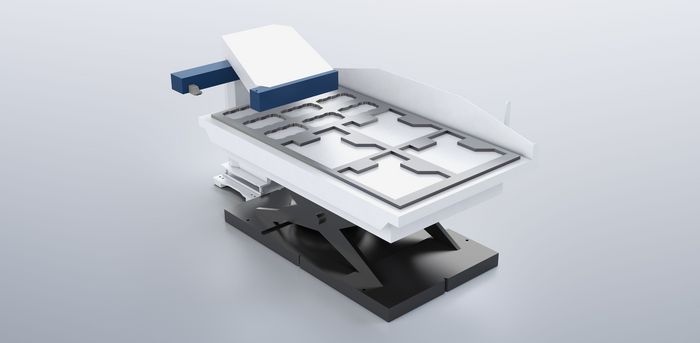

Automation components for punching and punch laser machines

Machines, coordinated automation variants and programming technology: you benefit from turnkey concepts from a one-stop supplier.

Contact

Services