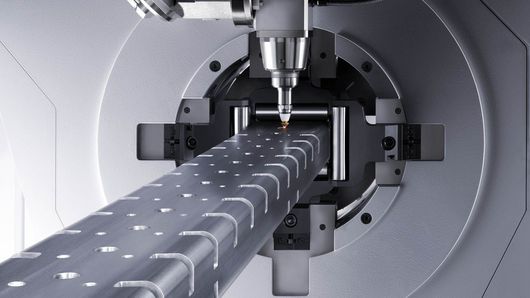

Gentle unloading and sorting

The TruLaser Tube part-removal station unloads your cut tubes particularly gently onto conveyor tables, into wire mesh boxes or into containers. Conveyor tables act as buffer for finished parts. From here, you can remove the parts at an ergonomic height parallel to production. The TruLaser Tube Series 7000 part-removal station also sorts finished parts. The waste conveyor belt disposes of waste in boxes parallel to production.

A conveyor belt disposes of scrap in boxes parallel to production.

The TruLaser Tube Series 7000 part-removal station not only unloads finished parts, but also sorts them.

Finished parts are removed gently onto conveyor tables.

TruLaser Tube 5000 with part-removal station

TruLaser Tube 5000 fiber with part-removal station

TruLaser Tube 7000 with part-removal station

|

Part-removal station

|

|

|---|---|

| Maximum outer circle diameter | 254 mm |

| Maximum finished part length | 6500 mm |

| Max. finished part length with finished part length option + 1.5 m | 8000 mm |

The technical data of all product versions as a download.

Automated machines work more productively, support material handling and increase process reliability. Equip your automation components with clever features.

You can unload cut tubes via the conveyor table if required

The waste conveyor belt conveniently disposes of scrap for you.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.