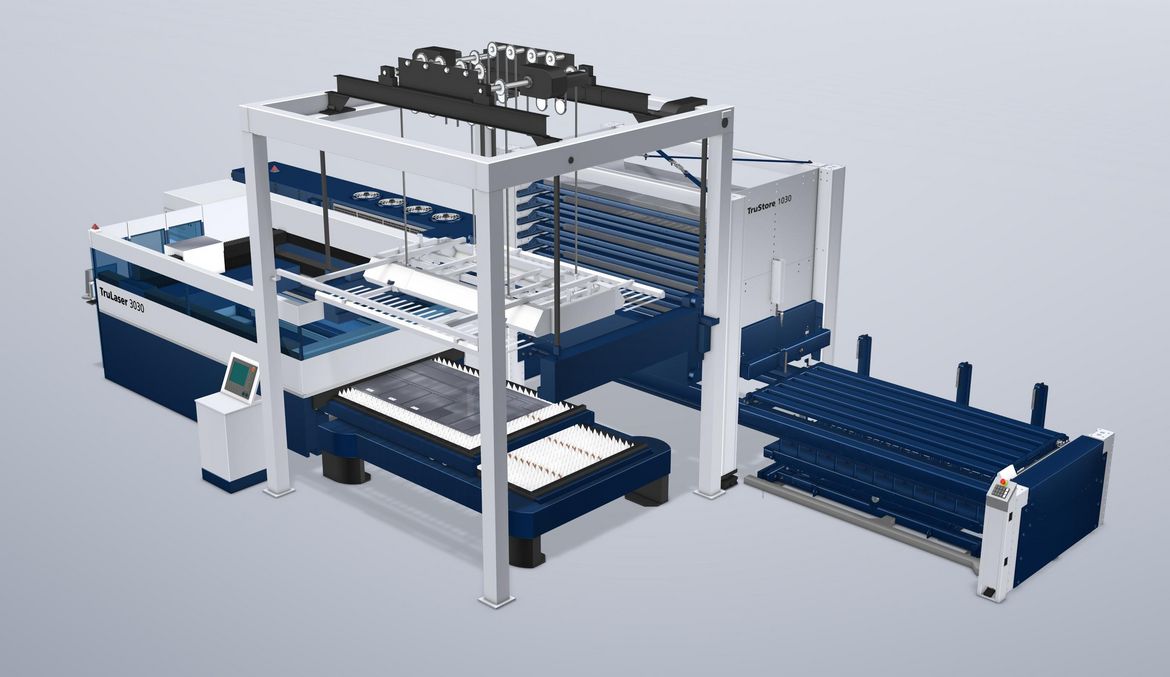

Fastest storage connection

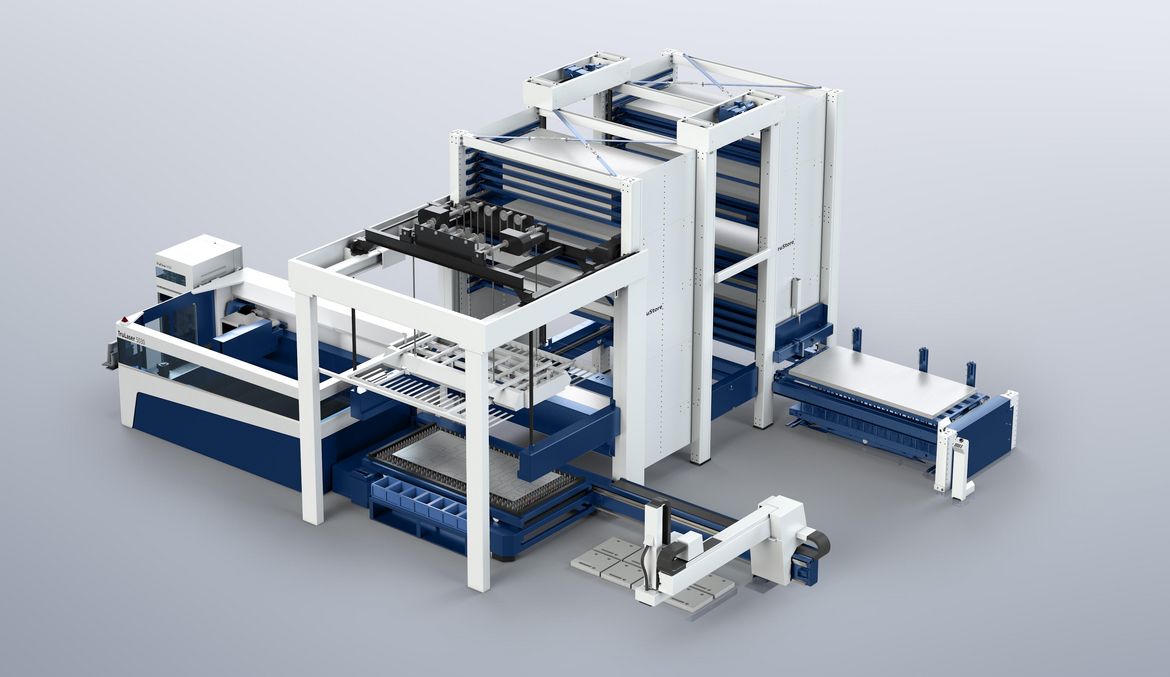

The frame solution, LiftMaster Store, is directly connected to the store and requires minimal space. In return, it offers more scope to design your production to meet your specific needs. Here, the LiftMaster Store is assisted by a number of tried-and-tested TRUMPF technologies. Examples include the suction frame with unloading rakes for automated loading and unloading, or the synchronous loader for increased productivity. With the independent pallet picker crane, the LiftMaster Store can quickly access pallets in the store. This makes it particularly well suited to automated scrap skeleton separation. Connection to up to three machines with multiple tool stations is made possible with the LiftMaster Store Linear.

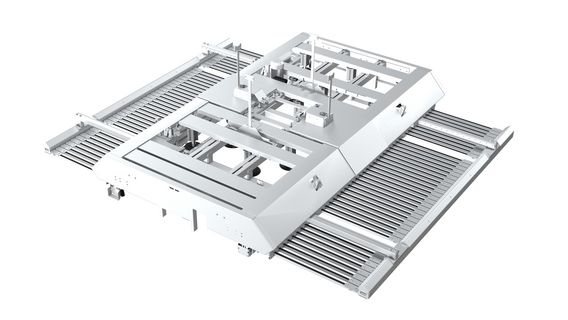

The LiftMaster Store accesses the store directly via a pallet picker crane.

With TruStore and SortMaster you can easily upgrade your LiftMaster Store to a processing cell.

The LiftMaster Store requires just 100 seconds for a complete loading and unloading cycle, including pallet change with the synchronous loader.

Produce in a single stroke and at under a minute per sheet.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.