Productivity squared

The TruPrint 2000 stands for the highest quality, robust processes and high productivity. With a build volume of 200 x 200 mm base and a height of 200 mm, it offers ideal possibilities. Thanks to the expanded build volume and the new spot base configuration with 80 µm, the TruPrint 2000 is the perfect system for the tool industry as well as for applications in the dental, medical or general industry.

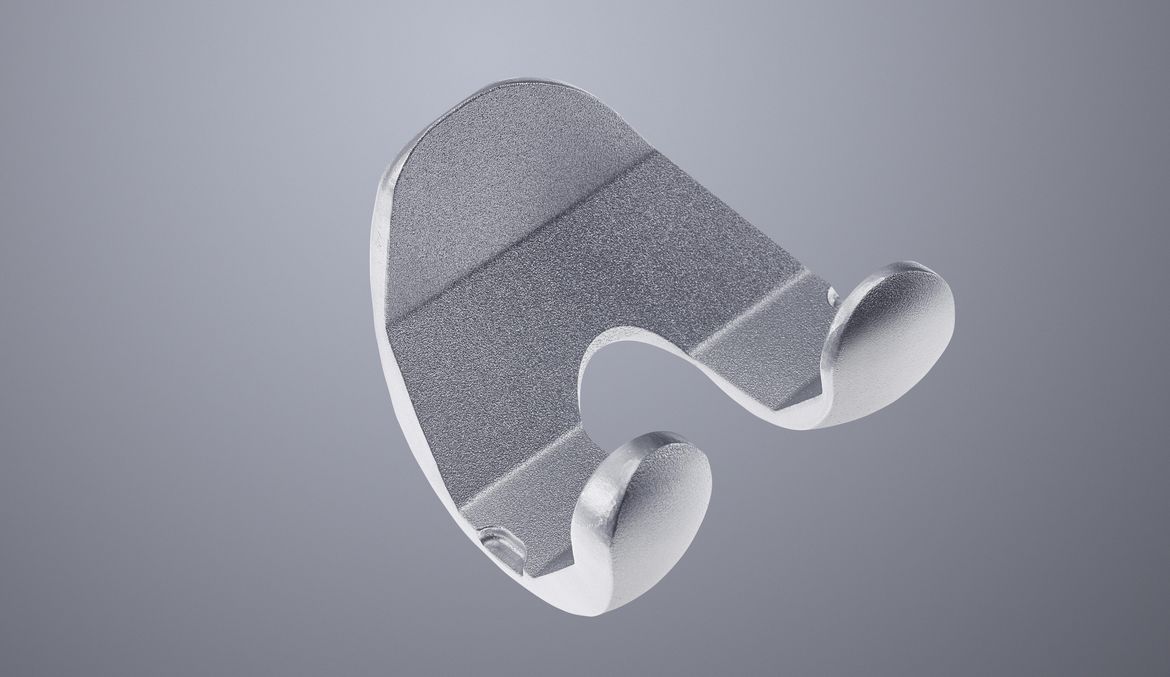

For example, up to 36% more RPDs (removable partial dentures) can be placed on the square build plate than on a round build plate with a diameter of 200 mm. With the 80 µm spot full-field multi-laser, users also benefit from our new dental parameters, with which they can print up to 30 RPDs in around 4 hours.

Thanks to the square base and build plate attachment underneath, components can be easily arranged – all the way into the corners.

The 500 W laser power and the 80 µm beam diameter with the multi-laser option deliver highly productive and excellent results.

The combination of build volume, laser power and re-coating time results in an economical machine concept for your series production.

With the adjustable spot diameter (55/80 µm) and detailed process analysis, you can enjoy a high level of process flexibility and expanded monitoring.

Benefit from easy and safe handling of powder and parts thanks to an inert, closed powder circuit.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.