The TruPrint 1000 Basic Edition is fitted with a 200 W fibre laser from TRUMPF with a wavelength of around 1,070 nm. The TruPrint 1000 Basic Edition also achieves optimum powder coating and laser exposure. This reduces non-productive times to a minimum. A tilting recoater speeds up the process.

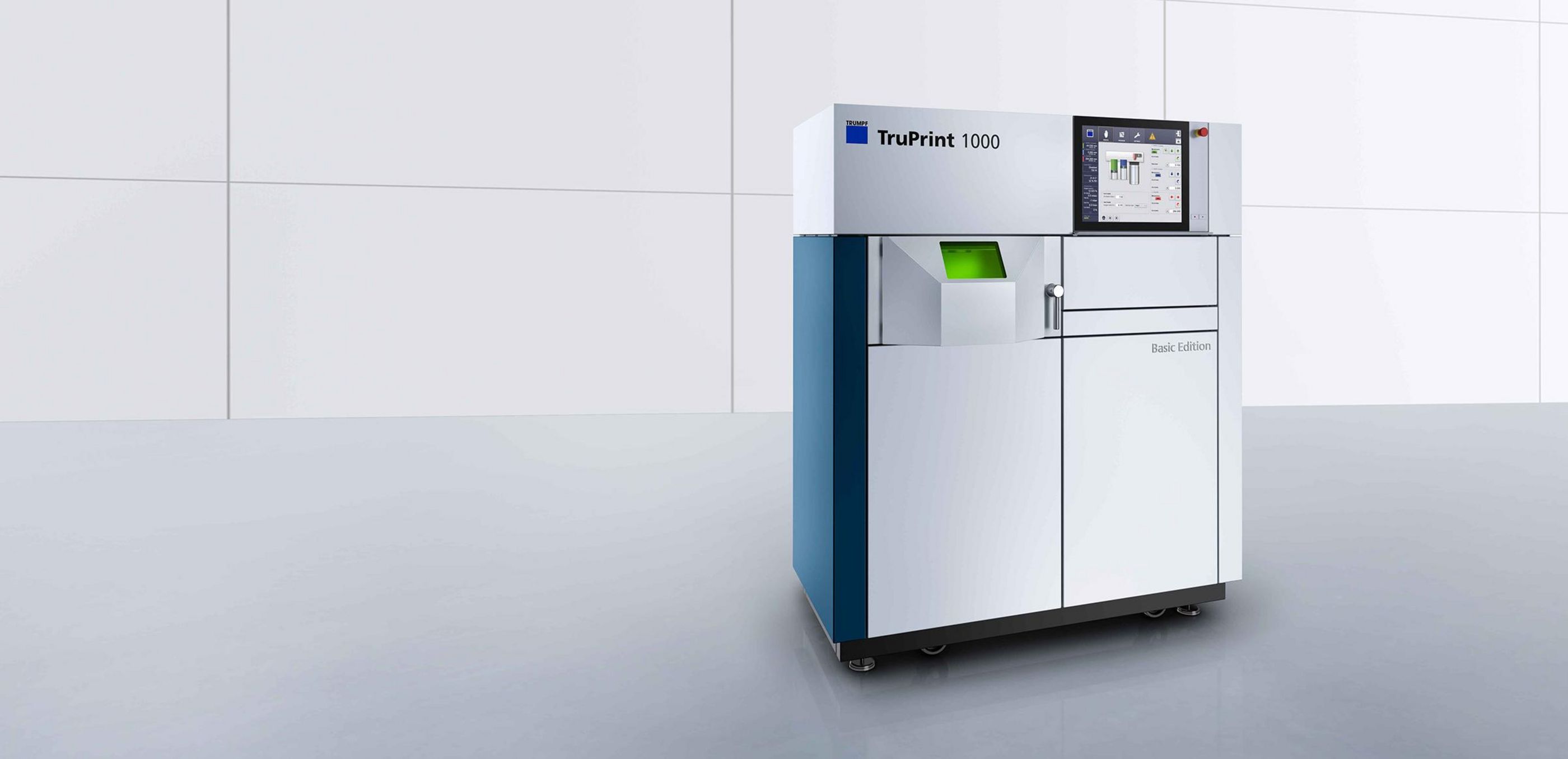

Simple metal 3D printing: affordable and robust

The TruPrint 1000 Basic Edition is based on a machine concept that has been tried and tested over many years. It has a build plate with a diameter of 98.5 mm for the production of up to 100 sections (crowns and bridges). The system is affordable and robust, intuitive to use and reliable. It also manufactures at a high speed. Optionally, the machine can be equipped with a glove box and an analogue sensor for monitoring the extremely low oxygen level in the build cylinder (required for titanium processing).

Get to grips with the technology quickly

For quick component production

Machine concept tried and tested over many years

Option with glove box

With live analyses and machine data reports

24/7 spare parts availability, remote support and highly qualified service engineers

Dentures manufactured with the TruPrint 1000 Basic Edition.

The TruPrint 1000 Basic Edition enables you to produce customised dental applications – such as dental crowns or single abutments – cost-effectively and to a high quality standard.

|

TruPrint 1000 Basic Edition

|

|

|---|---|

| Build volume (cylinder) | Durchmesser 98.5 mm x 100 mm Höhe |

| Processable raw materials | Schweißbare Metalle in Pulverform, wie z.B.: Edelstähle, Werkzeugstähle, Aluminium-[2], Nickelbasis-, Kobalt-Chrom-, Kupfer-, Titan-[2] oder Edelmetall-Legierungen[2], amorphe Metalle. Aktuelle Werkstoff- und Parameterverfügbarkeit auf Anfrage. [2] Mit Optionen verfügbar. |

| Beam diameter (standard) | 55 μm |

| Layer thickness | 10 μm - 50 μm |

| Build rate | 2 - 18 cm³/h 1 |

| Connection and consumption | |

| Electrical connection (voltage) | 230 V |

| Electrical connection (current intensity) | 7 A |

| Electrical connection (frequency) | 50/60 Hz |

| Shielding gas | Stickstoff, Argon |

| Structural design | |

| Dimensions (W x H x D) | 1445 mm x 1680 mm x 730 mm |

| Weight (including powder) | 650 kg |

The technical data of all product versions as a download.

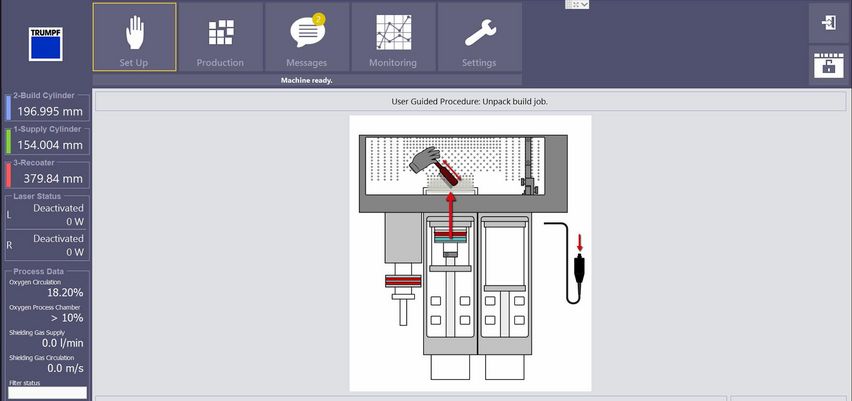

TruTops Print

TRUMPF provides the suitable software solution with TruTops Print so you can get the best out of the TruPrint machines.

The modern user interface summarises all functionalities in a clear overview and facilitates quick access to all functions. Maximum efficiency and productivity with optimum printing quality, reproducibility and support-reduced overhang construction are ensured thanks to the high degree of flexibility and the individual options for data preparation, such as z-segmentation, as well as the intuitive and clearly arranged parameter management with fully accessible parameters. The high quality of the generated vector data in the WZA file format can be verified with the integrated BuildJob Viewer.

Data preparation suitable for your workflow

TruTops Print is already connected with numerous CAD/CAM systems for a seamless data preparation workflow. This offers you the greatest possible flexibility when selecting the data preparation software. Decide for yourself which solution suits your workflow perfectly.

Optionally, the 3D printer can be equipped with a glove box, which replaces the conventional process chamber door with a door containing glove handles. This means that components can be unpacked in a protective atmosphere.

High-resolution oxygen sensor for controlling the shielding gas atmosphere with a measurement range of at least 100 ppm. This is particularly important when handling reactive materials such as titanium

TruPrint monitoring

With TRUMPF's intelligent monitoring solutions, you can monitor, analyse and calibrate the LFM process of the TruPrint machines with ease. You can then manufacture even more efficiently and achieve higher component quality. The professional monitoring process makes it possible to display and analyse sensor-based data. The range of services includes solutions for condition and performance monitoring.

Powders and parameters

We offer ready-to-use parameters for many common powder suppliers and key dental components.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

The actual build-up rate consisting of illumination and coating. Dependent on the configuration of the system, the process parameters, raw material and fill level.

Find your additive manufacturing solution for dental technology now!

Use the TruPrint product finder to discover which TruPrint machine is best suited to your dental technology application!