3D printing in premium quality: highly productive and compact

With the next generation of the TruPrint 1000, we are continuing our success story - with even higher productivity and premium quality thanks to the full-field multilaser and completely redesigned homogeneity of the gas flow. The 3D printer is intended for processing metal powders using the laser metal fusion process, also known as Powder Bed Fusion. Due to the high level of robustness and quality in 3D printing, the TruPrint 1000 is not only perfectly suited for the dental market, but also impressive in the R&D area or in small series production.

The new design of the TruPrint 1000 is optimally structured so that the machine fits through a standard door and can find its place in any laboratory, e.g. in the dental field or in universities.

With multilaser 2 x 200 W and automatic substrate plate change

Through redeveloped gas flow and improved laser focus stability

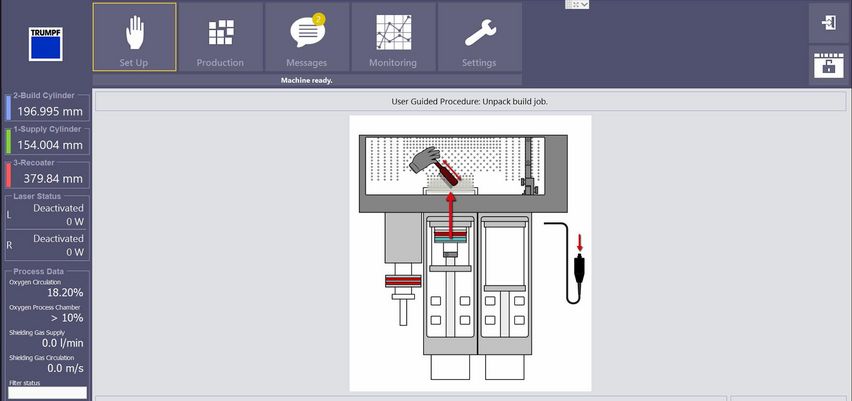

Inert powder cycle with glove box and interchangeable cylinders

With the adjustable spot diameter (55/80 µm) and detailed process analysis

Lower part costs through preform, multiplate and hybrid, digital chain

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

White paper