The setup of the TruLaser Cell 5030 Hotforming Edition is not only compact, but also extremely user-friendly and ergonomic. The rotary table is easily accessible not only from the front but also from the sides. The machine layout can be flexibly configured so that the hall layout can be planned in line with your requirements.

Your 3D laser cutting machine for hot-formed components

3D laser cutting

Would you like to start high-quality 3D cutting – with an attractive price-performance ratio and reduced initial risk? Then the TruLaser Cell 5030 Hot Forming Edition is the system for you. It is ideal for customers who wish to expand their production but do not yet require maximum productivity. The midrange system has most of the innovative functions of the TruLaser Cell 8030 and is superior to comparable products on the market in terms of dynamics, functions and robustness.

The machine's performance is excellent compared to market competitors in the segment thanks to good base machine dynamics combined with dynamic level 3.

The rotary table enables a short rotation time. Short non-productive times are possible in combination with optimised approach and departure motions.

Experience gained from the largest installed base design of 3D hot-forming machines has been applied to the new machine.

Optimum production processes due to functions such as X-Blast technology, FastLine Cell Basic or ObserveLine Comfort & Professional.

Hot-formed and laser-cut crossmember

Mass series parts can be processed cost-effectively on the TruLaser Cell 5030 Hotforming Edition thanks to its low initial investment. The NC programming also provides you with maximum flexibility for component geometry.

Laser-cut B-pillar

The TruLaser Cell 5030 Hotforming Edition reliably cuts 3D components, such as B-pillars for cars. The processing of hot-formed components with the laser is considerably more cost-effective than using standard processes. Thanks to the flexible laser tool, components can also be easily adapted to new requirements – even a later time.

|

TruLaser Cell 5030 Hotforming Edition

|

|

|---|---|

| Axis travel range | |

| Maximum number of axes | 5 |

| X axis travel range | 3300 mm |

| Y axis travel range | 1500 mm |

| Z axis travel range | 600 mm |

| B axis travel range | ± 135 ° |

| C axis travel range | n x 360 ° |

| Maximum workpiece size | |

| Maximum workpiece size in X | 2840 mm |

| Maximum workpiece size in Y | 1040 mm |

| Maximum workpiece size in Z | 370 mm |

| Maximum axis speeds | |

| Maximum axis speed, axially parallel in X | 60 m/min |

| Maximum axis speed, axially parallel in Y | 60 m/min |

| Maximum axis speed, axially parallel in Z | 60 m/min |

| Maximum axis speed, simultaneous | 104 m/min |

| Maximum axis speed of B axis | 60 1/min |

| Maximum axis speed of C axis | 60 1/min |

| Maximum axis accelerations | |

| Maximum axis acceleration, axially parallel in X | 9.5 m/s2 |

| Maximum axis acceleration, axially parallel in Y | 9.5 m/s2 |

| Maximum axis acceleration, axially parallel in Z | 9.5 m/s2 |

| Maximum axis acceleration, simultaneous | 16.5 m/s2 |

| Maximum axis acceleration of B axis | 200 rad/s2 |

| Maximum axis acceleration of C axis | 100 rad/s2 |

| Positioning accuracy | |

| Positioning accuracy of linear axes (X, Y, Z) | 0.08 mm |

| Positioning accuracy of rotary axes (B) | 0.015 ° |

| Laser | |

| Maximum laser power | 3000 W - 4000 W |

| Available lasers | TruFiber |

| Rotary table automation | |

| Maximum load per side | 260 kg |

| Work stations | 2 |

| Typical total non-productive time | 4.8 s |

| Typical rotation time | 2.4 s |

| Rotary plate diameter | 4000 mm |

| Working height | 700 mm |

The technical data of all product versions as a download.

TruTops Cell provides you with everything you need for the convenient programming of your 3D laser processing – no matter whether this is the programming of laser cutting, laser welding or laser metal deposition programs. It loads 3D CAD data via numerous interfaces, and corrects it if required. The system automatically creates cutting suggestions in all three dimensions. It also automatically suggests devices.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

You can select the perfect solid-state laser for your application, which you can then optimally combine with the TruLaser Cell 5030 Hotforming Edition.

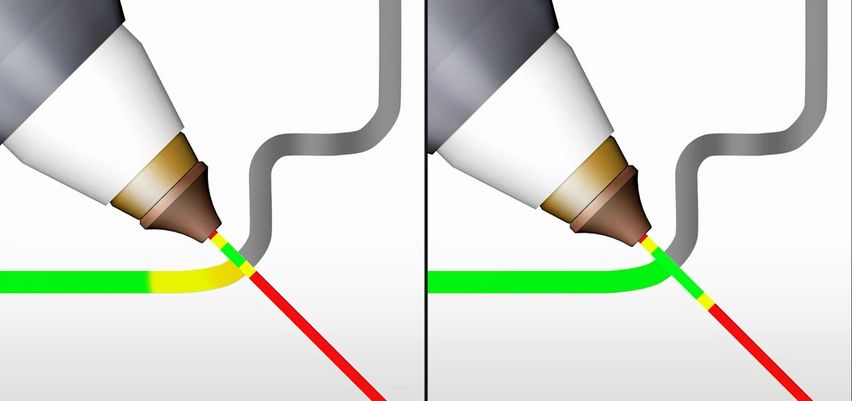

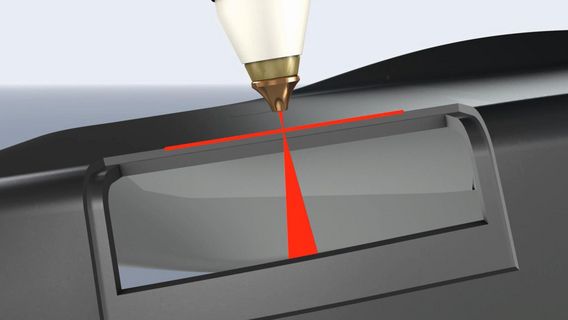

There are various reasons as to why cutting slugs remain in the finished part. With the ObserveLine Comfort optical measuring procedure, you detect this error quickly since this option checks every contour for a complete cut – all this is carried out twice as fast as with comparable systems on the market. ObserveLine Comfort has several advantages compared to measurement using distance regulation. The process reduces the measuring time and even smaller hole diameters and angled punching slugs can be measured.

Minor nozzle collisions can cause minimal incorrect positioning of the cutting optics, invisible to the operator. This results in increased rejects and associated costs. The ObserveLine Professional optical measuring procedure checks the positioning accuracy of the machine at regular, freely definable intervals, without the need for refitting and with virtually no effects on the cycle time. Incorrect positioning is detected and the number of rejects is reduced.

Smart Optics Setup is a fixture attached to the machine base unit which cuts test sheets and readjusts the machine. Implementation is even easier thanks to standardised macros, saving time and money.

FocusLine enables the program-controlled setting of the focal position depending on the type of material and the material thickness. The position is adjusted using a pressurised mirror, influencing the curvature of its surface.

You can integrate new devices easily and cost effectively into the machine control via the pneumatic and electrical interface.

TruTops Cell Basic enables you to adjust programs more easily, more quickly and more reliably directly at the machine. Navigating within the NC program is incredibly simple, as the contour to be changed with the corresponding NC text can be selected by a simple click of the mouse. All changes made are visualised immediately and ensure unprecedented reliability when working in the program.

FastLine Cell Basic improves and optimises the approach behaviour of the machine during piercing for the cutting of the contour. Depending on the type of material and the material thickness, as well as the number of contours to be processed, you can increase the productivity of your system by up to 20%.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.