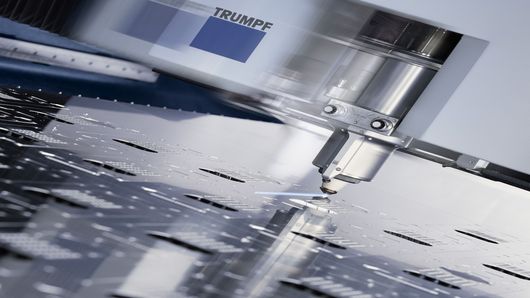

Do you want to cut 2D as well as 3D components, profiles or tubes? The machines from TRUMPF give you the ideal equipment for this. As a pioneer in 3D laser processing, TRUMPF provides beam sources and components for beam guidance, as well as complete machines and systems containing optimally coordinated components. The systems excel with a range of unique selling points, such as the patented 2in1 fibre. Comprehensive 3D technology data that is checked independently of the beam source makes it easier for you to get started in the 3D world.

Contact

Services