The highest productivity and best part costs for series production

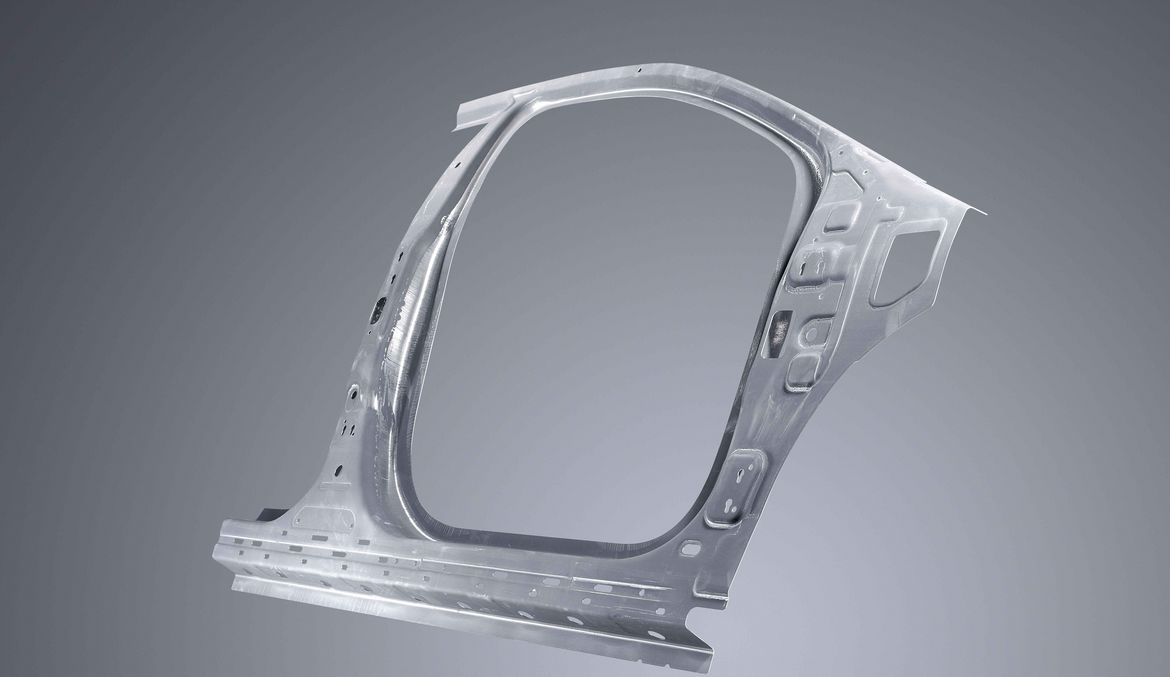

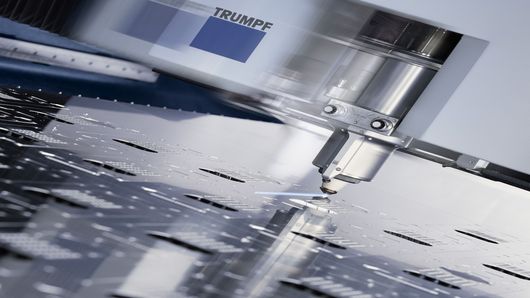

Broad range of variants in series production: many customers find themselves facing this challenge – regardless of whether they manufacture small, medium, or large quantities. That's where the TruLaser 8000 Coil Edition, a highly productive and flexible laser blanking system from TRUMPF, comes in. Sheet metal processors often use press lines for series production, but have to manufacture bending tools for each new product variant – an expensive and time-consuming process. Tool-free and flexible processing with a laser directly from the coil saves time, materials and money. But even compared to conventional laser cutting from the sheet, laser cutting from the coil offers massive advantages in terms of cost and efficiency.

Equipped with an ARKU precision leveller, the ARKU belt system together with tried and tested TRUMPF quality combine to form a highly automated, turn-key entire system with many advantages for customers. In collaboration with SIEMENS, an innovative control was developed – from coil unwinding, aligning and laser cutting to completely integrated, robot-based component removal. All steps are automatically programmed by TruTops Boost, up to part unloading with the robot.

Every sheet comes from a coil. Enjoy the benefits of a significantly reduced procurement price for coils as opposed to sheet goods.

Continuous nesting optimally utilises your materials, which in turn significantly reduces scrap and thus component costs.

Within one very short cycle (less than 10 seconds), new material is brought into the machine via conveyor, the portion that is cut is transported to the unloading place, and at the same time, the scrap material is disposed of.

The integrated robot and gripper system allows for significantly quicker discharge times and flexibility when it comes to removing components.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.