Welding quality control in sync with the manufacturing process

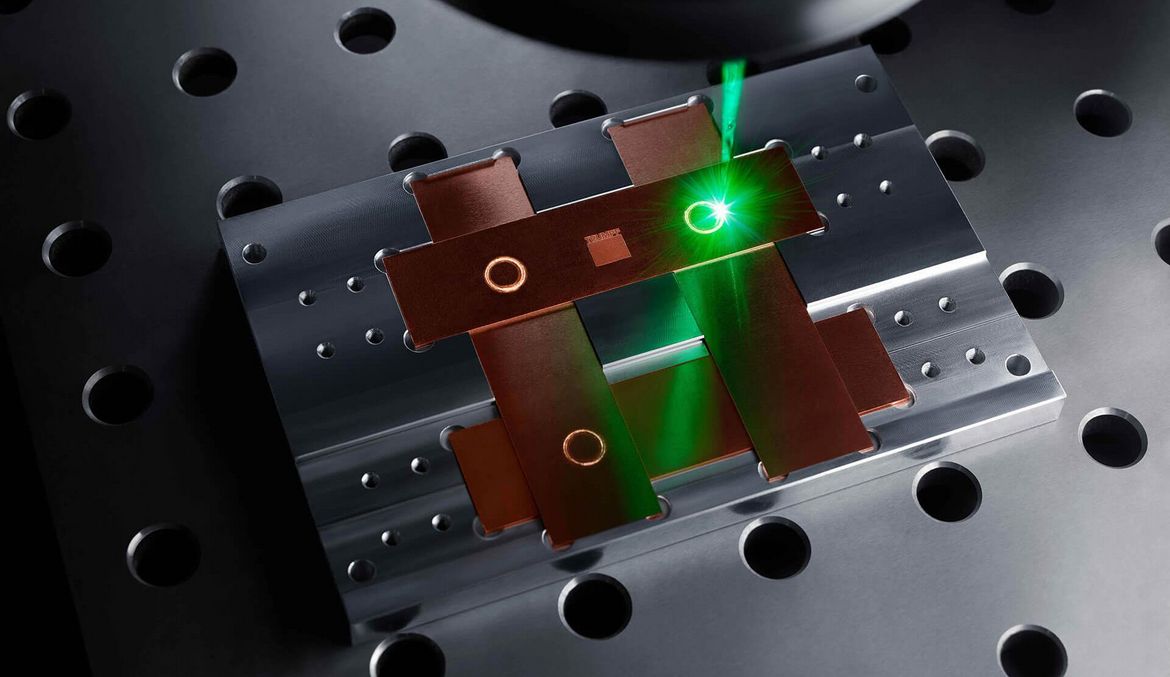

The VisionLine OCT Check process sensor system ensures reliable and precise welding depth monitoring. The use of optical coherence tomography (OCT) enables quality assurance, such as the measurement of the weld bead depth during deep-welding processes, to be conducted in sync with the manufacturing process. The geometry of the solidified weld seam is measured by an additional OCT scan. The seamless interaction of PFO and OCT means that it is feasible to measure the capillary depth in sync with production throughout the PFO's entire work area, eliminating the need for parameter adjustments.

The robust OCT design and smart integration into the optical system enable measurements to be taken even under variable ambient conditions.

For minimal interfaces and simple plant integration

User-friendly software interface

Quick result availability for low cycle times

Testing of each part with 100% traceability of the welding depth along the entire weld seam

All features of VisionLine Detect and VisionLine OCT Detect are already included.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Only available with 3rd generation PFO.

- Detailed information on the available optical settings can be found in the data sheet.