Keeping an eye on everything with VisionLine

With VisionLine image processing, TRUMPF is setting new standards in object recognition, distance measurement, user-friendliness and process reliability. VisionLine automatically detects the component position, forwards this information to the control, and ensures that the marking is always in the right place. Not even edges or more complex components present a problem.

Optimize your marking process with automatic component and position recognition. Benefit from real time feature detection during positioning.

State-of-the-art lighting allows you to create optimum conditions for marking multiple materials – even on highly reflective surfaces.

The attribute library supports the person doing the set-up work as they create their image processing tasks.

VisionLine comes with sensitive cameras with high resolution, which contribute to efficient production thanks to short exposure times and fast image recording.

VisionLine's modular structure with its individual functions can be precisely adapted to your task.

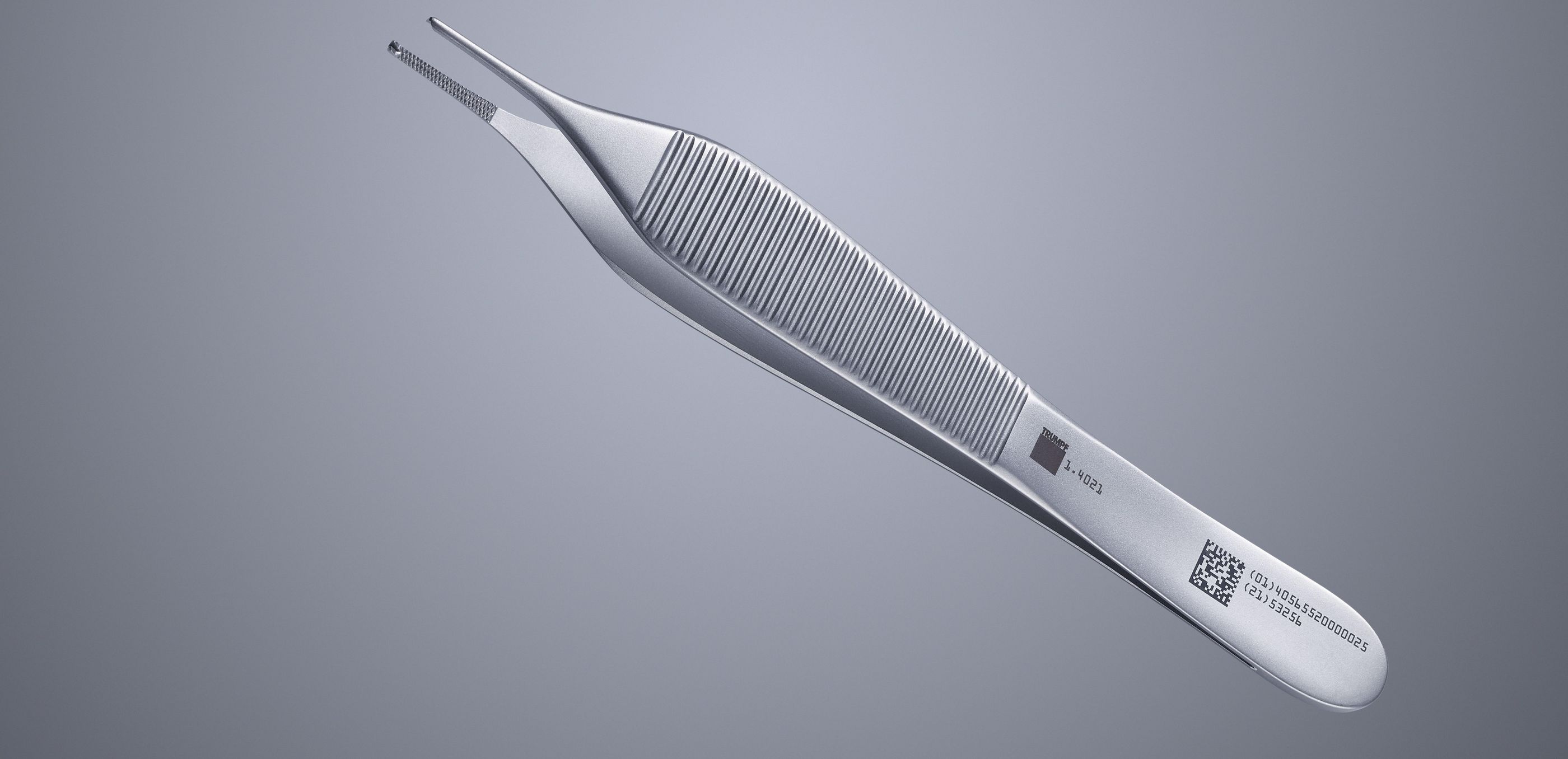

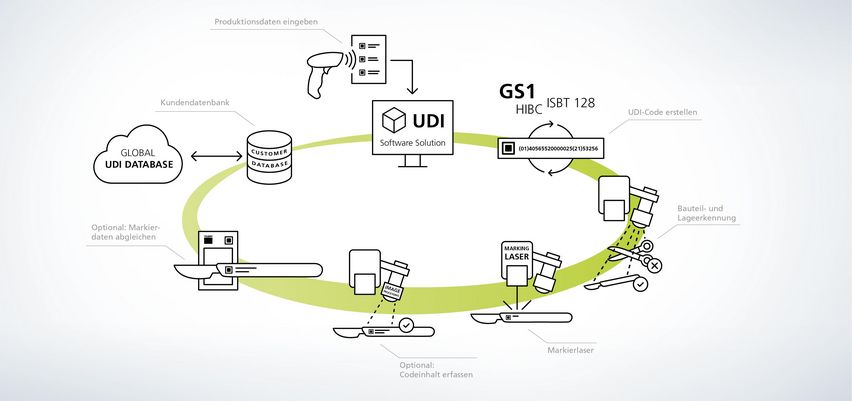

UDI identification in medical technology

VisionLine facilitates automatic or manual positioning of the marking data, such as for UDI-compatible marking, for example, including documentation.

Marking of text and code

VisionLine image processing finds the right position before the marking process, and, after marking, checks whether the content and quality of this meets the specifications.

Position recognition and content check with VisionLine

VisionLine image processing automatically finds, recognises and learns the component position and can read and evaluate content such as Data Matrix Codes.

Marking gearbox parts

When marking components, VisionLine enhances quality control by incorporating a "distance measurement" function.

Readout on several processing planes

Bar codes, data matrix codes and texts can be read out after laser marking, their quality can be assessed and the results received can be reliably documented.

Processing large components

VisionLine can determine the distance to the workpiece precisely. With the stitching function – the placing of images in a row – you even have large components with high resolutions perfectly in view.

VisionLine Detect

Edge-detection offers the option of integrating simple characteristics recognition on the workpiece in the production process for position correction. The appropriate distinguishing features (for example, blots, circles, lines or intercept points) can be selected from a template library for many application scenarios.

VisionLine Model

Image processing offers the identification of taught geometric features for position correction on the workpiece. It is easy to integrate the image processing program in the production process. Sufficient lighting can be ensured by the optionally available lighting strips so that the function is guaranteed even under difficult industrial conditions.

VisionLine Code

You can ensure that the content is correct and legible by reading back the marked 1D or 2D code. In addition to reading out a code, its quality can also be checked.

VisionLine OCR

VisionLine OCR offers character recognition (OCR – Optical Character Recognition) and evaluation of the system and machine fonts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.