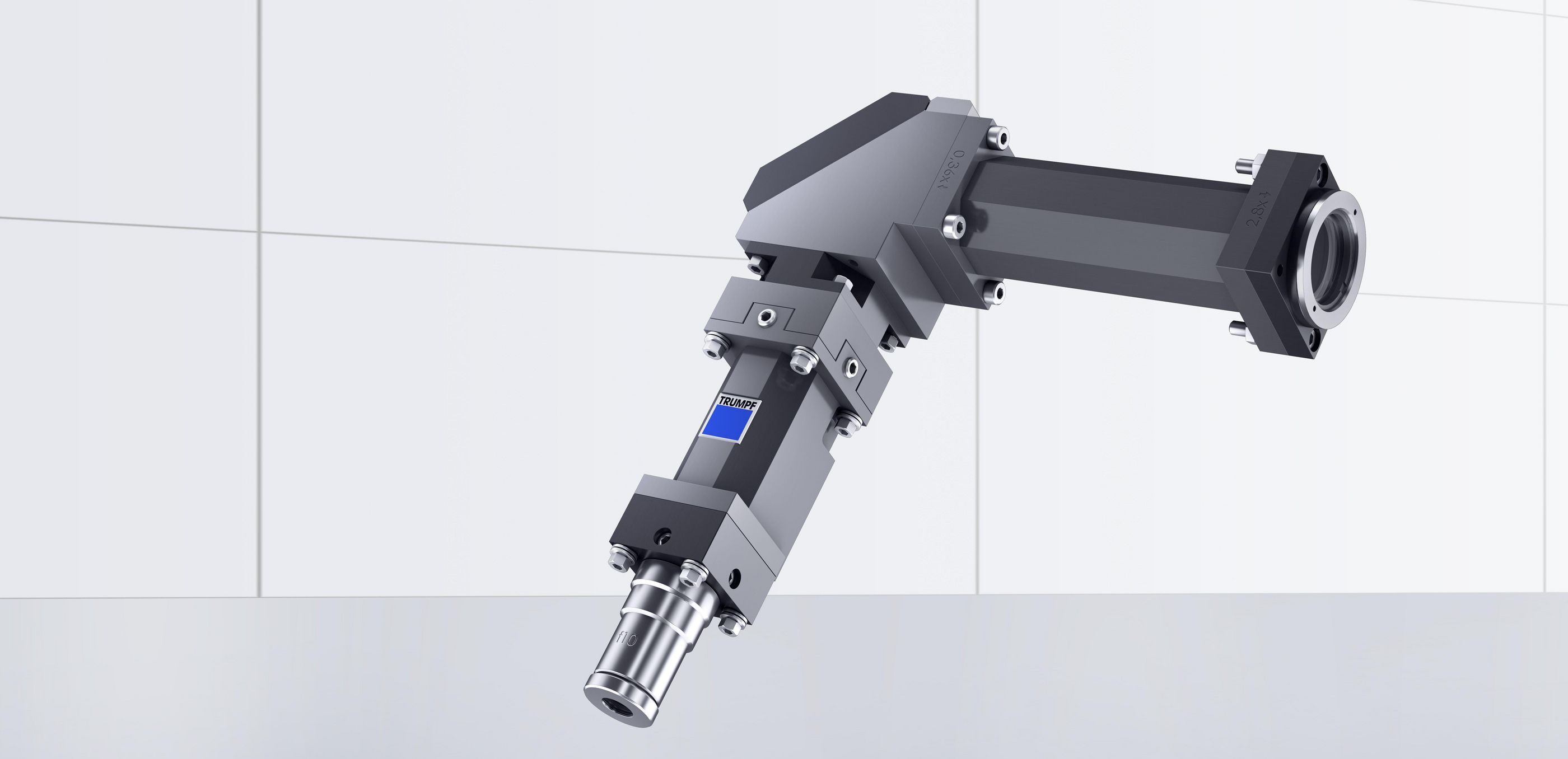

The TOP series design features an especially compact, lightweight and robust construction and can be subjected to high accelerations.

Optics for beam formation

You are optimally equipped for every laser processing task with our beam formation elements of the TOP product group. Whether it is for cutting glass, welding transparent materials or soldering galvanised sheet metal parts – TOP Cleave-2, TOP Cleave-2 PRO, TOP Weld and TOP Braze will all win you over with very high processing quality and speed for a variety of materials. If necessary, we will develop a solution for beam formation that is suitable for your requirements.

Welding with TOP Weld generates highly transparent seams. The high level of tightness makes it possible to encapsulate fluids or gases.

Thanks to the fact that there are no complex process steps or additional materials, you will protect your resources and your budget with the TOP product group

Benefit from quick cutting with TOP Cleave-2, which requires basically no post-processing.

Laser, processing head, optics, beam formation – we have everything in our portfolio at TRUMPF, perfectly coordinated for your requirements.

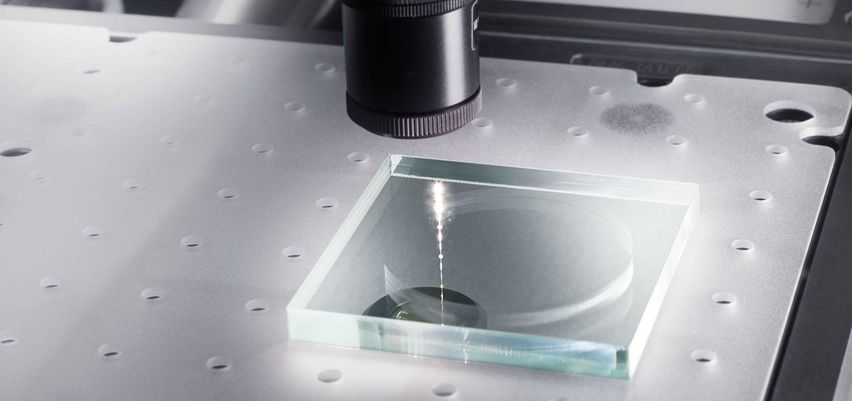

Cutting ultra-thin glass

Laser modification cutting allows ultra-thin glass (50 µm) to be cut with the highest edge quality. This significantly increases the rigidity.

Modifying glass

Extreme thicknesses greater than 8 mm can be efficiently processed and then cut with TRUMPF TruMicro lasers and TOP Cleave optics. After cutting, it is not necessary to post-process the cutting edge, such as by grinding or polishing.

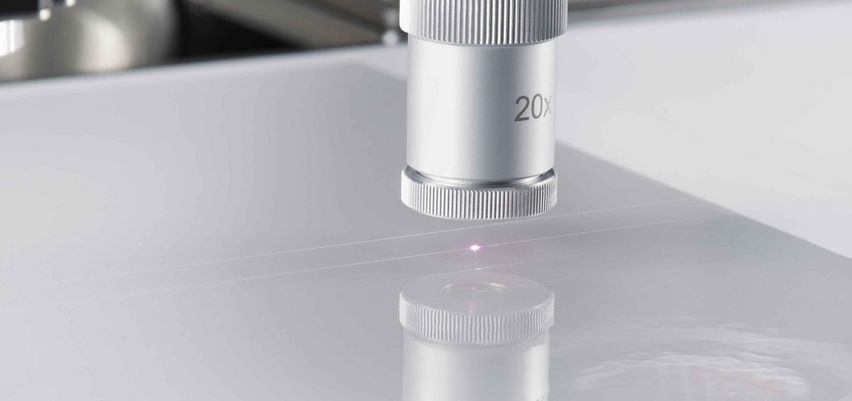

Glass welding

TRUMPF TOP Weld optics focus femtosecond-long laser pulses to weld glass to glass or glass to metal with high precision. The result is a high-tensile and practically invisible bond.

Any contour and the smallest geometries

With TOP Cleave focusing optics you can freely and precisely cut contours down to a hundredth of a millimetre. With extremely short laser pulses, you can modify a narrow area along any desired separating line. The change creates an intrinsic weakening, and the glass will break off in a controlled manner and with smooth edges.

Laser cutting of glass tubes

Residue-free laser cutting of glass tubes with TOP Cleave optics. The glass tubes are processed with aberration-corrected, non-diffracting beams and ultrashort laser pulses. This allows glass tubes smaller than 15mm in diameter to have cycle times in the range of 0.1s per cut. Typical applications are in medical technology, with products such as ampoules, syringes and vials.

Selective laser etching of complex inner contours in glass tubes

Glass tubes modified using aberration-corrected, non-diffracting beams can be used in combination with a selective etching process to produce even complex inner contours.

Glass welding with TruMicro and TOP Weld

Thanks to TOP Weld, it is possible to weld materials in an industrial environment with permanent high stability. The weld seams are also water- and gas-tight.

Brazing in body construction

Whether it is for a roof seam or a boot lid – the TOP Braze focusing optics make it possible to braze hot-dip galvanised metal sheets with in-situ pre-treatment by the processing laser.

|

TOP Cleave-2

|

TOP Weld

|

|

|---|---|---|

| Laser parameters | ||

| Wavelength | 1030 nm | 1030 nm |

| Maximum pulse energy | 500 µJ | 500 µJ |

| Optics configuration 1 | ||

| Extensions |

0.36 x

0.5 x 0.67 x 1.5 x 2 x 2.8 x |

0.5 x

0.36 x |

| Available focusing lenses |

f = 20 mm, NA=0.2

f = 10 mm, NA=0.4 |

20 x (f = 10 mm) |

| Designed for raw beam diameter | 5 mm | 5 mm |

| Structural design | ||

| Dimensions (W x H x D) | 40 mm x 240 mm x 40 mm (configuration example) | 40 mm x 240 mm x 40 mm (configuration example) |

| Weight | Depending on configuration 0.62 kg | Depending on configuration 0.62 kg |

| Compatibility | ||

| Available lasers | TruMicro Series 5000, TruMicro Series 2000 | TruMicro Series 5000, TruMicro Series 2000 |

The technical data of all product versions as a download.

TOP Cleave-2

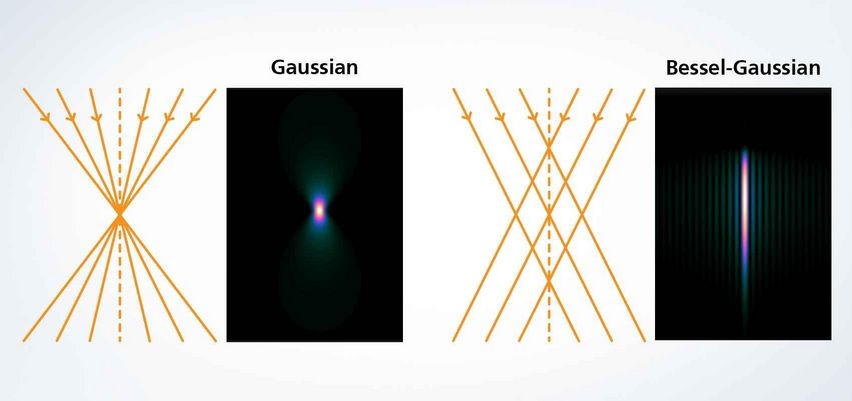

With TOP Cleave-2 you can save on individual process steps because the large panes can be coated directly and separation can be carried out subsequently. In particular, very thin, hardened glass can be processed in the best possible way. The focusing optics for highly dynamic cutting distribute the intensity of the laser light along the beam axis which lengthens the focus. Depending on the pulse energy, the laser pulses modify the entire interior cutting surface of a pane that is 700 µm thick, for example, in a single pass. You can achieve cutting speeds of up to 1000 mm/s with the TruMicro Series; TOP Cleave-2 ensures outstanding edge quality.

TOP Cleave-2 PRO

The PRO module expands on the TOP Cleave-2 optics for cutting transparent materials. The preferred direction in the beam profile can greatly reduce the work required for the downstream cutting step on the workpiece. The PRO module also enables increased distance between the modifications and thus increased feed rates thanks to the targeted crack guidance between the individual laser modifications. The TOP Cleave-2 with PRO module can be used across the entire thickness spectrum for processes with higher demands. Both workpieces that are difficult to separate, such as architectural glass with thicknesses in the range of 8 mm, and ultra-thin glass for which extremely low separation forces are required, can be processed using the focusing optics.

TOP Weld

TOP Weld is the first processing optics for welding transparent materials or transparent to opaque materials (for example, glass to metal) without intermediate layers. It has never been possible before to weld materials in an industrial environment with permanent high strength. The material properties do not have to be matched to each other. The focusing optics distribute the laser energy along the joining zone, tailored to the specific situation, while focusing position tolerances can be maximised. Compared to existing methods, larger gaps can be bridged, up to 10 µm.

TOP Braze

TOP Braze makes it possible to braze galvanised metal sheets or aluminium components in the bodywork sector without spatter or pores, for example for roof seams and boot lids. These different materials can be processed consistently and over a large area at high processing speeds of over 4 m/min. The result: smooth surfaces and sharp edges. You receive the complete solution from TRUMPF, all from one source, with the TruDisk Series, optical laser cable and processing head with beam formation optics.

In addition to a range of processing optics, TRUMPF also offers you the right beam sources for these. This allows you to find exactly the right combination for your application and requirements – all from a single source. When it comes to beam sources, TRUMPF offers all industrially relevant lasers. You can rely on our experts and put your trust in us. We always have the best solution in mind for your production tasks and we will advise you independently of any preferred technologies.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

Other optics configurations are available on request.