Jordan Yost loves being an entrepreneur. "I've been fascinated by metalworking all my life. When I sold my car rental business, I rediscovered my passion for metal," says the 40-year-old founder. He spent two years exploring the industry and its work processes, looking for ways to improve while analysing the business potential. In the end, the deciding factor was a friend's job shop in Las Vegas, which produces parts for trade fair stands. Jordan was able to look behind the scenes and gain a wealth of practical experience before taking the plunge together with his father Barry in 2018, establishing Precision Tube Laser (PTL) – a metal processing service provider.

From zero to one hundred

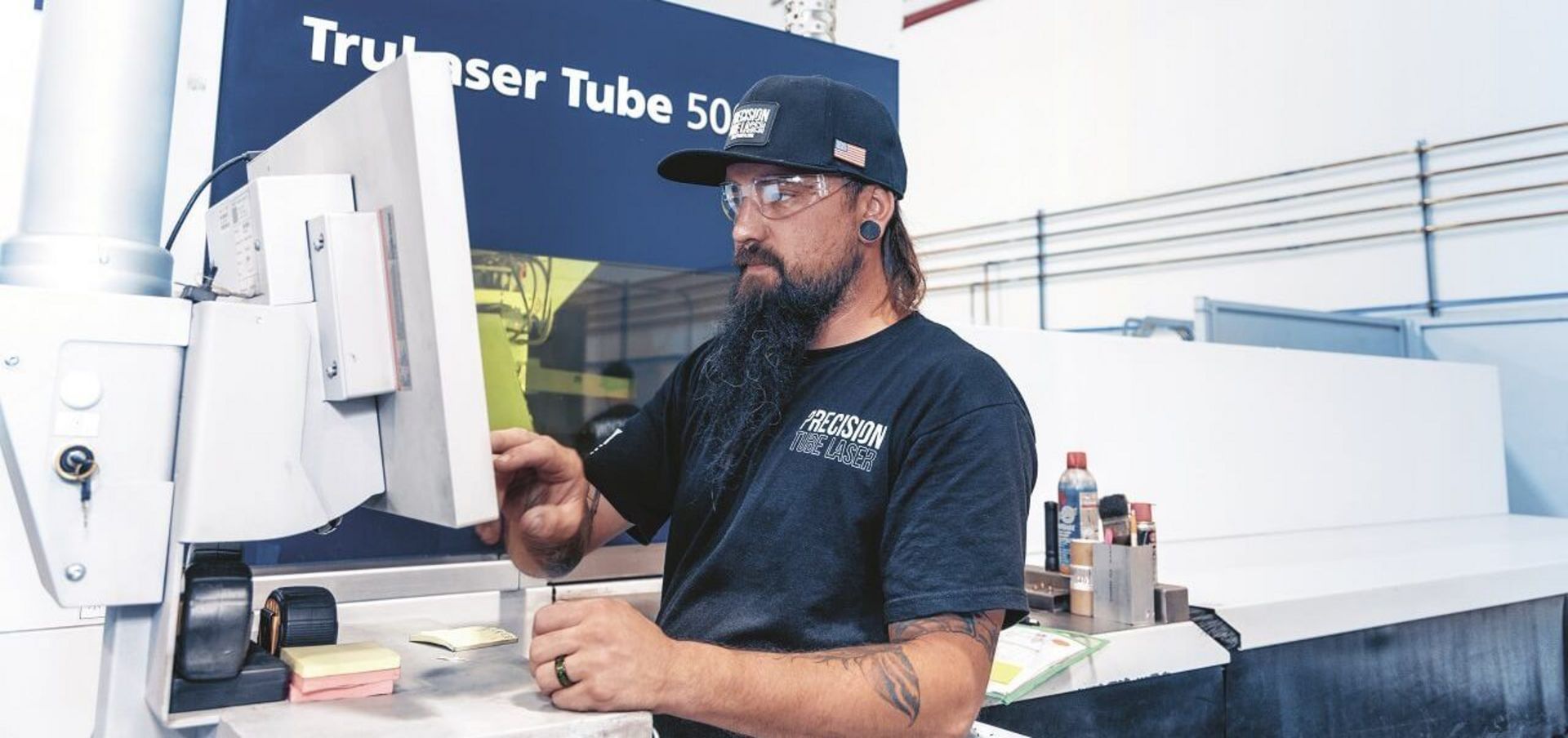

The entrepreneurial approach was entirely innovative – offering lead times of three to five days, no minimum order requirements and tempting prices. Jordan Yost's strategic positioning of the company, transforming it into a nationally recognised destination for sheet metal part processing, deserves acknowledgment. "Small companies in the manufacturing industry find it difficult to find job shops that meet their requirements. Our company supports small businesses in their day-to-day business by supplying high-quality sheet metal parts so that they can concentrate on their main area of expertise," says Jordan, explaining his business model. To achieve its vision of an on-demand solution, PTL required extensive automation and access to the best technical equipment available on the market. The production facilities on South Pearl Street in Las Vegas run almost exclusively with machine tools from TRUMPF: TruLaser Tube 5000 fiber, TruLaser 1040 fiber, TruBend 5170 with ToolMaster. They cut and bend metal for air conditioning system manufacturers, trade stand builders, automotive suppliers and many other users.

55,000 followers on Instagram

TRUMPF's software facilitates rapid setup of machines for a range of components and ensures reliable production control. "We love technology and are continuously investing in the digitalization of our company," says Jordan. In March 2023, PTL added a TruLaser Center 7030 to their machine pool, which they refer to as a game changer. "Integrating the new machine into our work processes takes time," explains the company founder. But ultimately, this gives the job shop an advantage over its competitors. "In the future, we anticipate automating production around the clock with a 25-person team." Precision Tube Laser has prioritised digital marketing from the outset, leveraging platforms such as Instagram and YouTube to cultivate a robust community and foster engagement. The videos and posts provide a wealth of expert knowledge. It's all about achieving optimal part design. While aesthetics are important, PTL also prioritises the ability to seamlessly transfer the geometry directly to its machines. "We engage in a dialogue while drawing up the design plans until we can machine the metal effectively," Jordan explains. This boosts customers' confidence in Precision Tube Laser as the best possible partner for the job.

Industry goes digital

"In the early days, we had our backs to the wall several times. There were ups and downs, and we really had to grit our teeth," recalls the company founder. "Yet, we've managed to carve out a lucrative niche, consistently enhancing and expanding year after year." We now receive between 200 and 300 email inquiries every day. These result in 30 to 50 orders, with volumes ranging from one-offs to batches of multiple tens of thousands of parts. Annual sales remain reliably in the millions. Less than five percent of orders come from the Las Vegas region. The remainder comes from customers dotted all over the USA, with demand on the east coast in particular growing rapidly. Yost continues: "In early 2023, our customer base was still around 1,200 companies. We now have more than 1,500, of which 95% return to PTL time and again." This shows that the industry is changing and is becoming more technically open-minded and digital. "Making a contribution to this is a great feeling."

Jordan Yost intends to maintain his entrepreneurial focus and continue to drive PTL forward. The order volume would justify doubling the team, but he is keen to keep the HR structure lean. With a growing level of automation, Precision Tube Laser can undoubtedly excel further. Nevertheless, growth will not be pursued merely for the sake of expansion. "We feel like one big family, where everyone keeps an eye on everyone else. We want it to stay that way," says Jordan, with a broad grin on his face.