TRUMPF Smart Factory in Ditzingen

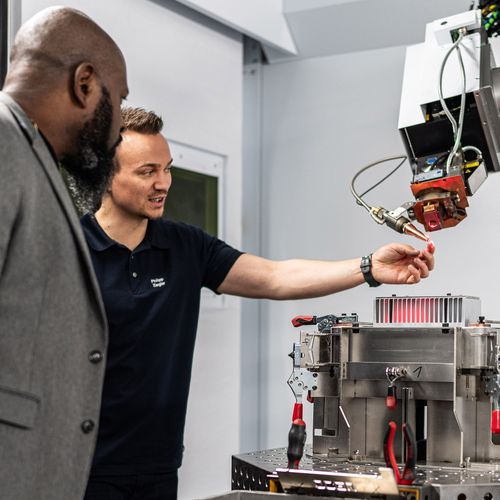

Your solution starts here – with a reliable partner by your side!

Whether you're a small family business or a medium-sized company, at TRUMPF's customer centre, we prioritise you and your challenges. Our experts analyse your needs and work with you to develop bespoke solutions for your metal processing. We will be by your side not just today, but for the long term, offering innovative technologies, reliable service and personalised support.

Make an appointment now and find out how we can future-proof your production facility!

In numbers: the intelligent factory in Ditzingen

Experience the future of your production facility – visit us today!

At our smart factory in Ditzingen, you can see first-hand how people and machines work seamlessly together. Intelligent systems ensure flexible, efficient and transparent production that directly enhances your manufacturing process.

Benefit from automated processes that shorten your throughput times and ease the pressure on your employees. Digital wizards help you to keep track of orders and stocks – anytime, anywhere. Our solutions seamlessly integrate machines – not just from TRUMPF, but also from third-party providers – ensuring a continuous and uninterrupted manufacturing process.

Thanks to intelligent monitoring systems, you can identify malfunctions early and prevent unplanned downtime. This is how you maximise machine utilisation and ensure long-term productive manufacturing.

1. Control Center

This is where the various strands come together. All orders are generated, controlled and can be experienced live in action in the Control Center. Track&Trace facilitates complete transparency and localisation of the individual orders throughout the entire shop floor. Put us to the test!

2. Application Center

You experience the variety of metal and tubes here. We provide advice for part design in terms of design, production time and cost efficiency. Your options and your production take centre stage.

3. AI-supported sorting

The Sorting Guide provides assistance to the operator directly at the laser cutting machine during the sorting procedure. After removing a part from the sheet, the parts which belong to this order are marked in colour in a screen. See for yourself how artificial intelligence increases the efficiency at the interface between the laser cutting machine and the factory flow.

4. Smart material flow

Up to 40% of valuable resources are still being allocated to non-value-adding activities. There is a better way: you will optimise your shop floor and therefore the entire production with a transparent material flow and automated guided vehicle systems.

5. Autonomous production

Within the Smart Factory area, we will demonstrate autonomous processes – four machines and one large-scale storage system work together, independent of technologies, within fully automated systems. We also supply our own in-house TRUMPF machine production with real parts for production here.

6. Integration of partner machines

Smart procedures are only possible if everyone is getting along: this is why TRUMPF opens its doors and forms cooperation partnerships. This means that we can get the best out of all of the systems for your solution.

7. Networked processing cell for the sheet metal process chain

Procedural progress, utilisation, malfunction – all status data and status information can be called up in real time. It is possible to analyse the entire production with this data to make it easy to detect inefficiencies and bottlenecks. But that's not all! Machines and machine apps actively help the operator process the orders.

The following machines can be viewed

Insight into the Smart Factory in Ditzingen