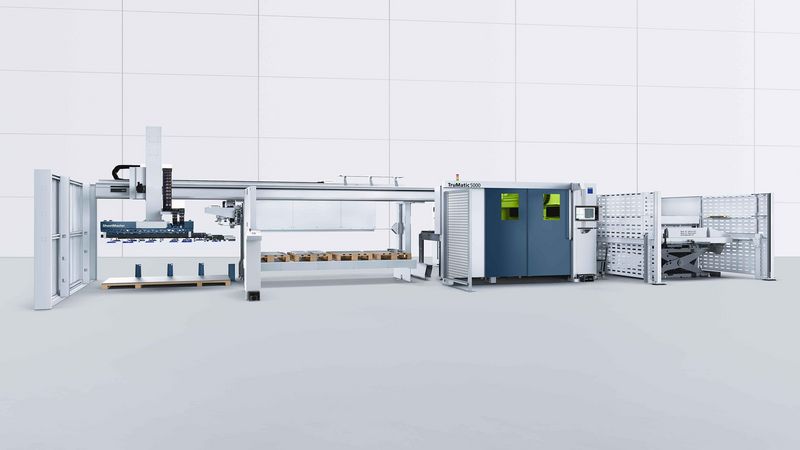

Machines & systems

Machine tools and laser systems - that's what we do. See our customized solutions for yourself. To ensure that you remain competitive and productive, we are constantly driving forward the development of our machines. In addition to precise mechanics, this also includes intelligent sensors, assistance systems and the networking of your production. Visit us and turn your production into the production of tomorrow.