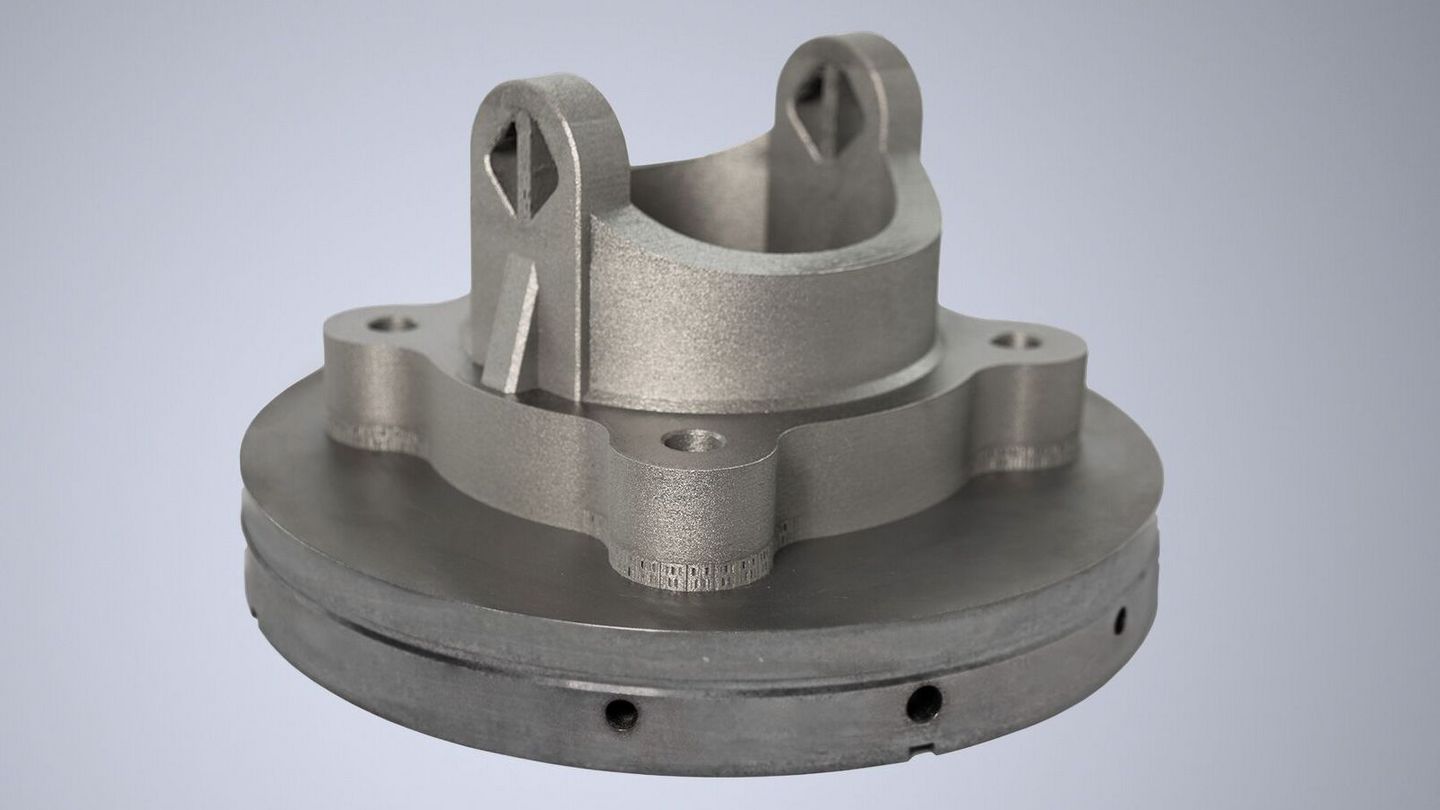

Voluminous component: Cardan suspension

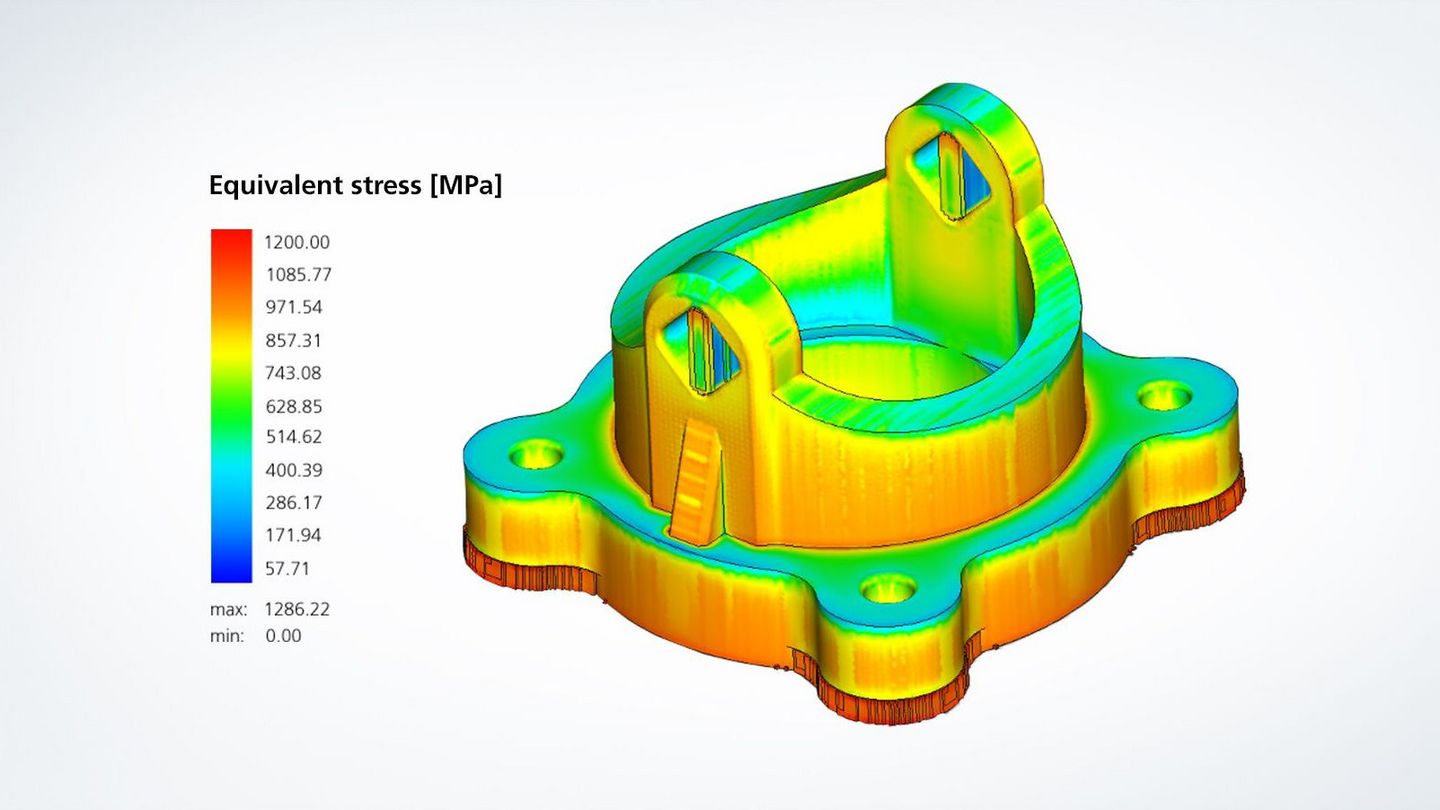

The range of parts that can be manufactured with PBF is expanded by the 500 °C preheating option of the TruPrint 5000. The residual stress of the parts is significantly reduced, especially in the case of volume changes and support connections.

The 500 °C preheating makes it possible to print the Cardan bearing, also called a gimbal. This significantly reduces the residual stress in the titanium component, thereby opening up entirely new possibilities in design, especially in the construction of more solid components.

Get in touch with our additive manufacturing experts!

Do you have a component that you would like to 3D print? Would you like to know what potential savings there are, and what advantages you could benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Facts & figures about the example part

Material: Ti6Al4V

Weight: 4.4 kg

Construction duration: 24.1 h

Number of layers: 2,053 at 60 µm

Created by: TRUMPF