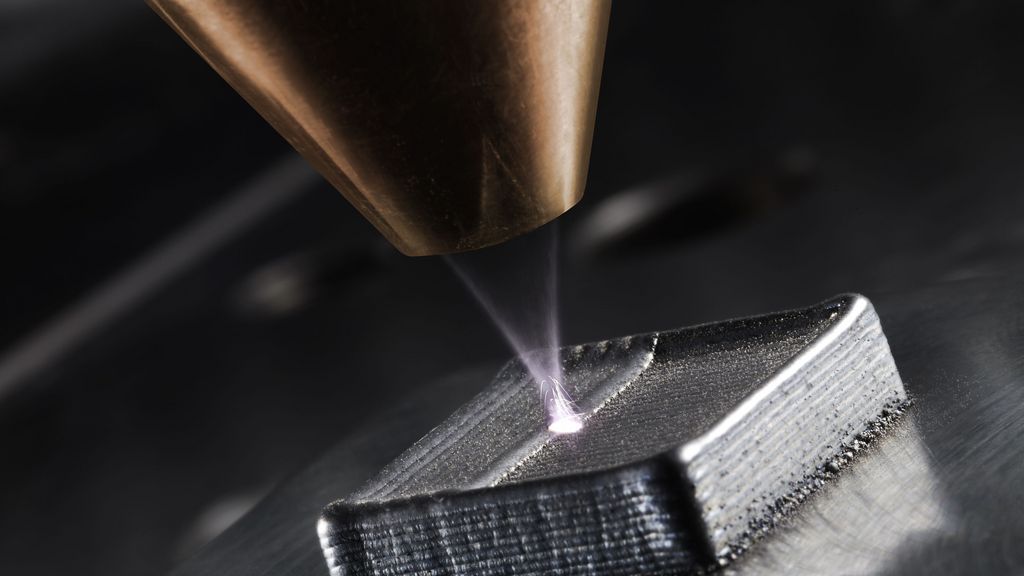

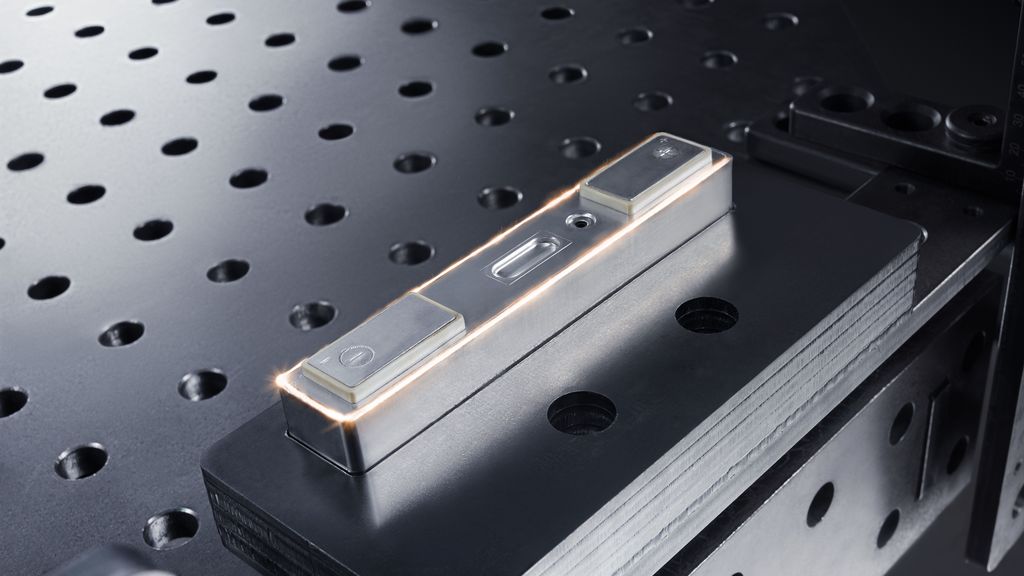

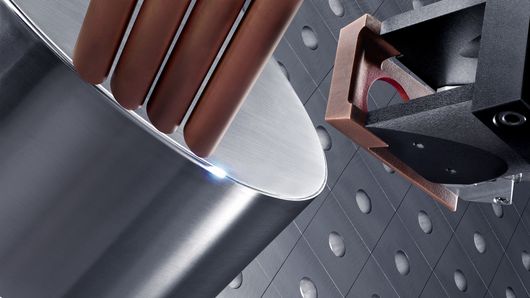

Intercity express trains, gear parts for cars and trucks, air bag sleeves, pacemakers - weld seams and weld points can be found in a great variety of locations. Hardly any other tool is as versatile as a laser: It can be used to create extremely fine weld points with a diameter of just one millimeter as well as deep penetration seams which are meters long. Very narrow seam geometries are created with a large depth/width ratio with a minimum of distortion. Lasers weld materials both with a high melting temperature and high heat conductivity. Thanks to the minimal melt and short controllable melting time, they can sometimes even join materials which otherwise could not be welded at all or would be very difficult to weld. Filler material is used if required.

Laser welding

A laser beam can join metal in different ways. It can join workpieces at the surface or produce deep weld seams. It can be combined with conventional welding processes and can also be used for soldering.

Discover the versatility of lasers

Contact