During laser drilling, a short laser pulse with high irradiance delivers energy to the workpiece in a very short time. This melts and vaporizes the material. The greater the pulse energy, the more material melts and vaporizes. During vaporization, the volume of material in the borehole increases abruptly and high pressure is created. This vapor pressure forces the molten material out of the borehole. Laser processing with ultrashort pulse lasers in the picosecond range is a speciality. The material is vaporized directly from the solid state by sublimation without melting the material - the component is not heated in the process. Over time, several drilling processes have developed from the basic principle.

Drilling

During laser drilling, the laser beam generates very fine to large holes in a variety of materials in a non-contact procedure.

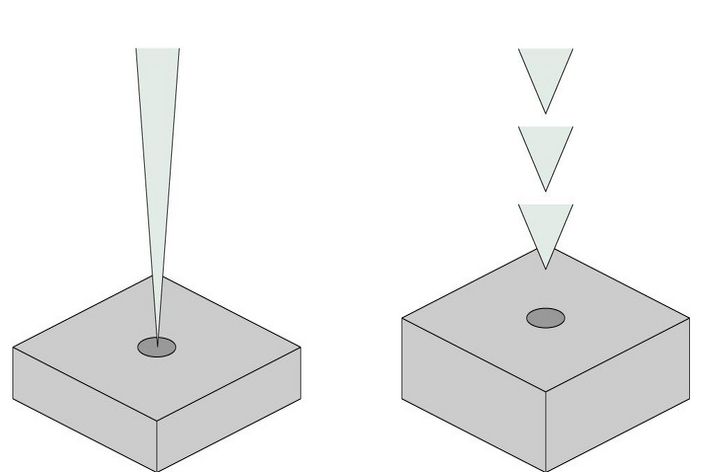

Single pulse drilling and percussion drilling

In the simplest case, a single laser pulse with comparatively high pulse energy creates the hole. In this way, many holes can be created very quickly. In percussion drilling, the hole is created by several laser pulses with a shorter pulse duration and pulse energy. This drilling method produces deeper and more precise holes than single-pulse drilling. Percussion drilling also enables smaller hole diameters.

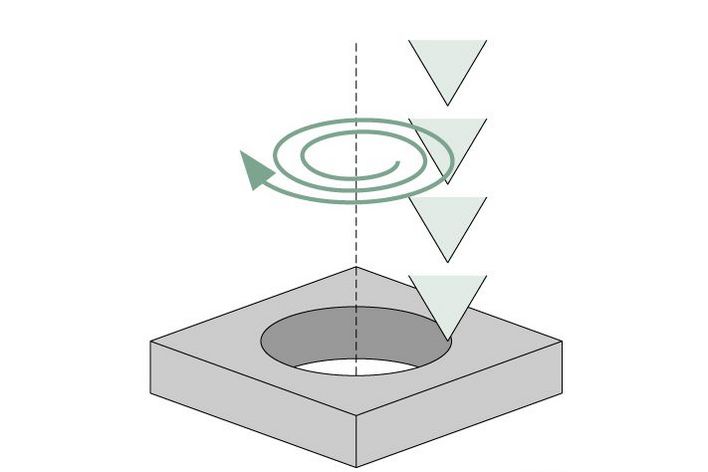

Trepanning drilling

In trepanning, the hole is also created by several laser pulses. First, the laser drills a start hole using percussion drilling. It then enlarges the start hole by traveling over the workpiece in several, increasingly larger circular paths. Most of the molten material is driven downwards out of the drill hole.

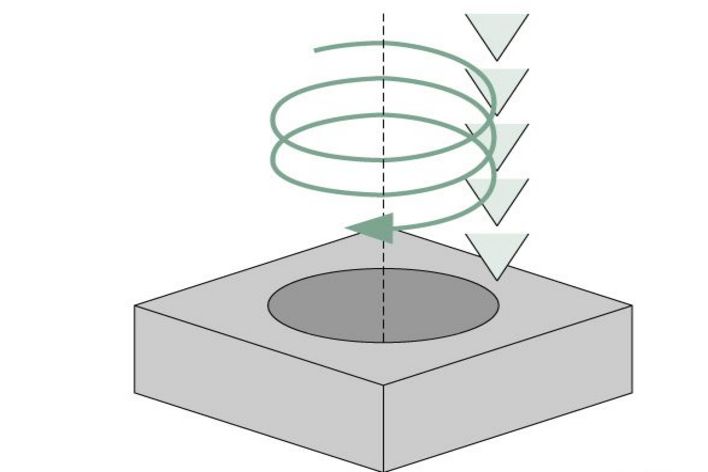

Helical drilling

Unlike trepanning, helical drilling does not create a start hole. The laser travels in a circular path over the material from the very first pulses. This causes a lot of material to escape upwards. The laser works its way downwards in a spiral staircase shape. The focus can be adjusted so that it is always at the bottom of the hole. Once the laser has penetrated the material, a few more rounds can be added. These are used to widen the underside of the hole and smooth the edges. Helical drilling can be used to create very large and deep drill holes of high quality.

Products

Work easily and flexibly

Quick and cost-effective

Accurate, proven, and efficient