Due to the large range of forms, shears, and coatings, you are provided with numerous application possibilities.

Punching tools

Regardless of whether you are looking for a standard or special solution, you can always choose the right tool from the largest portfolio on the market. Look forward to competent advice and custom-made products that can be used right away! Our knowledge from more than 40 years of tool development and production is always included.

Choose the perfect punching tool for any application from the largest portfolio in the world.

Obtain optimal results due to our numerous years of knowledge in development and production.

80 % of all tools are delivered within 24 hours.

Make use of our consultation services and make your daily work easier and faster with additional services.

All-around service

Punching tools and accessories

Punching

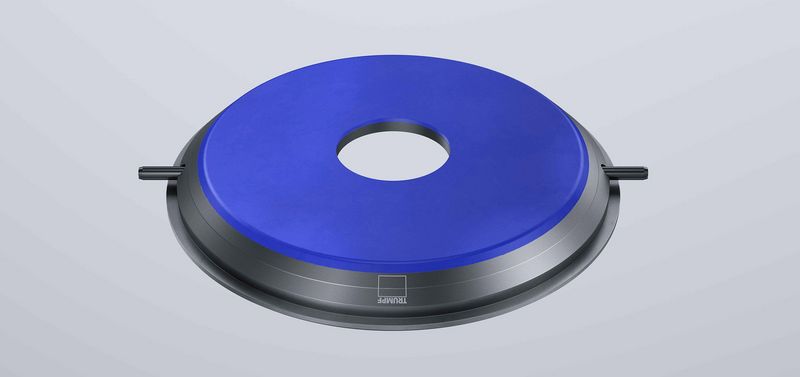

Tools from first-class steels, created with the latest manufacturing technologies are the best prerequisite for your production. The Classic punching tool system is the leading tool system for punching and punch laser machines. Due to the broad range of forms, shears, coatings, and accessories, you can use it with flexibility. With the standard EasyUse, simple set up is guaranteed. MultiTool makes your machine even more productive as it integrates up to ten different punching and die inserts in one tool. Its strengths really come into play during the processing of sheet metal parts with a variety of small punching operations.

Punching tools

Cutting

Cutting sheets is one of the most important applications on a punching machine. You can always find the perfect solution from us with tools for normal slitting contours, for separating cuts on forms, or for visible edges without nibbling marks. The ejector MultiTool is particularly suited to the reliable removal of small parts. If you would like to separate your finished parts directly from the remaining parts, the ejector tool for sorting is the perfect choice. With the patented film slitting tool with ball tip, you can slit your films perfectly without leaving scratches or marks on the sheet – for every conceivable contour.

Cutting tools

Forming

Forming tools enable you to deform your sheet metal parts. Examples include the tapping tool for the cost-effective creation of chipless threads, the MultiBend for bends up to 90°, or the roller tool for straight or curved forms in any length. You can also use a deburring tool and produce sheet parts on your punching or punch laser machine completely burr-free, thereby saving yourself costly post-processing. The size 5 tools also enable you to produce forms which are longer and higher than ever before – even on a TruPunch 1000.

Application examples

Forming tools

Marking

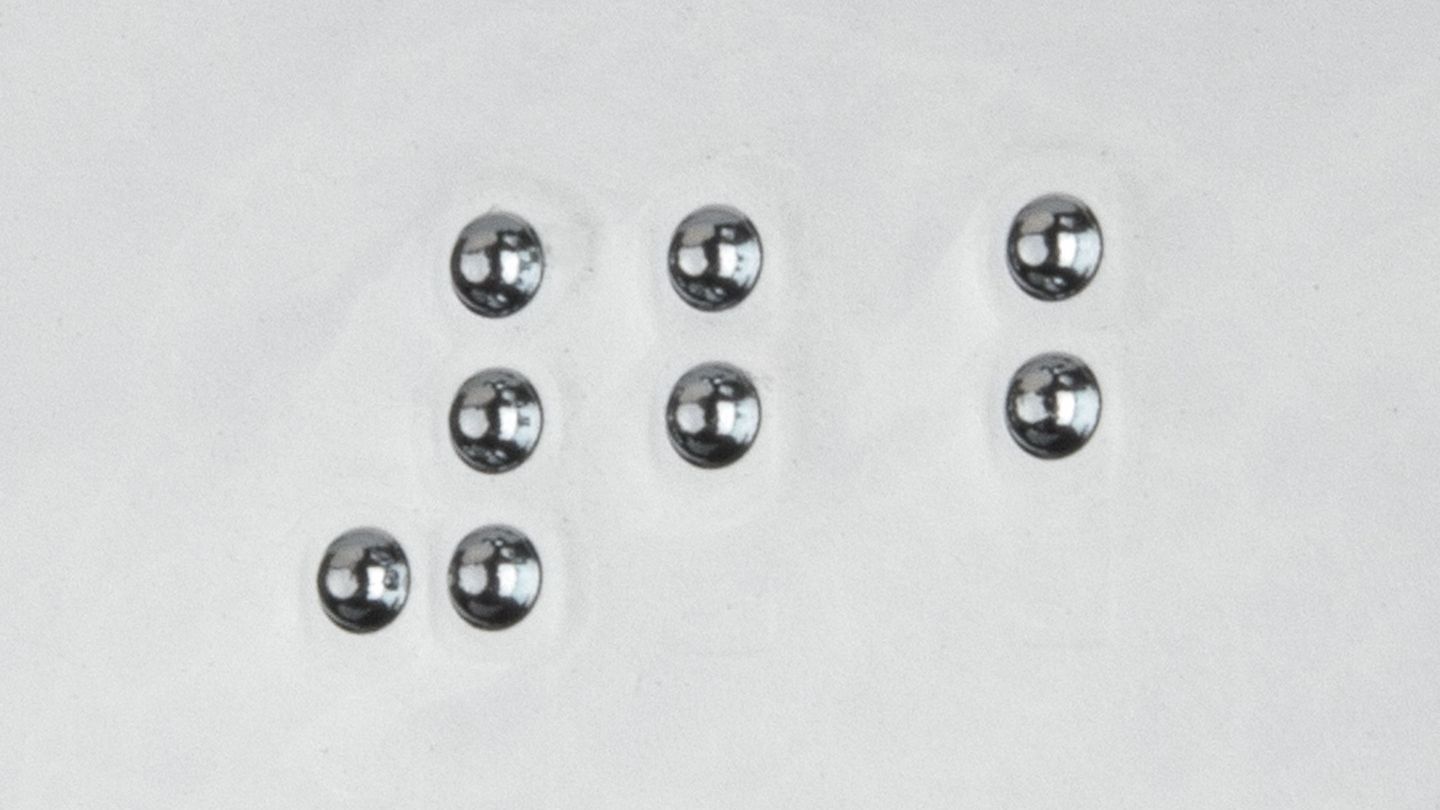

The identification of sheet metal parts is becoming ever more important – whether for manufacturing, legal or quality reasons. In the process you are creating transparency and documenting the responsibility of the manufacturer for the part they have produced. Using the engraving tool, you can mark sheet metal parts with flexibility in path mode and with the highest quality because the marking process does not produce chips. The Easy Type MultiTool is well suited for numerous different letters and numbers. You can use this one tool for all the numbers and letters of the alphabet, as well as numerous special characters. Last but not least, TRUMPF also provides solutions for marking components from below.

Application examples

Marking tools

Accessories

Precise adjustment and regular regrinding of the tools are crucial for high-quality punching results and long tool life. We have accessories such as our EasyUse shim, clever products for low-scratch processing, as well as additional equipment for your punching processes to make the set up and maintenance of your punching tools easier. The fully automatic QuickSharp tool sharpener ensures perfect sharpening. With the RTC tool cassettes, you can set up tools in no time at all.

Accessories for your punching tools

All-around service

Fast, flexible, and affordable: With TRUMPF punching tools you not only benefit from the best quality, but also from all-around service support. Free additional services which make your everyday punching processes easier, complete adherence to schedule facilitates your planning, and comprehensive trial offers provide you with the flexibility you need.

Price/performance

Optimum tool quality and a comprehensive range of free additional offers are a bonus of your investment.

Your advantages

- Punching with reduced noise and punching force with less sheet deformation using free punching shears

- Simple set up with free EasyUse scale on the die and shims

- Double the service life for cluster tools due to free TiCN coating

Speed

Quality and service: For TRUMPF this also means high availability and fast delivery times.

Your advantages

- Order tools quickly and 24/7 in the E-Shop

- Dispatch of your standard tools on the same day due to 24/7 production

- Programming of special tools even before your ordered tool is received through downloads in the MyTRUMPF customer portal

Flexibility

Does your customer have requirements that you cannot yet meet and you would like to first get a feel for particular applications? Then test new machine functions and tools for a specific period of time with the "Trial Production" service.

Your advantages

- Testing of new applications on your punching or punch laser machine, such as the MultiBend, MultiShear etc.

- Test activation of the machine function including corresponding test tool

- Consulting from TRUMPF experts during the test phase

Financing

We can offer you attractive financing models for set-up and grinding devices. Guarantee the long operational capability of your tools and the best punching results. Invest now in the fully automatic grinding unit QuickSharp, QuickSet, or QuickLoad.

Your advantages

- Extension of your tool lives through attractive hire purchase models for set-up and grinding tools

- Optimal financial planning certainty through fixed installments over the entire period

- Once the period has expired: The set-up and grinding tools become your property