When it comes to quality, you should leave nothing to chance. Even during their development, spare parts, machines, lasers, and laser systems from TRUMPF are coordinated with each other to the finest detail. This allows us to not just achieve high process reliability, but also to offer spare parts that function according to the plug & play principle and require no adjustment whatsoever. So that it remains like this, TRUMPF ensures the highest quality standards.

Your investment should pay off in the long term. Spare parts from TRUMPF - also called Genuine Parts - help with this. The reason: With spare parts specifically designed for your product, you are guaranteed to produce parts more safely, reliably, and productively.

An overview of your benefits

Perfectly matched to your TRUMPF machine right from the get-go, our spare parts ensure your performance and productivity are maximized over the long term.

At TRUMPF, you can get the spare part you need at any time and as quickly as possible, no matter where your production is.

Should a replacement be necessary, we guarantee the quality of our products with "Xchange" beyond the warranty.

Our expertise gives you the competitive edge. Our experts are always ready to provide you with advice and support from ordering to installation and maintenance.

The low adjustment effort minimizes the idle times of your machine.

TRUMPF E-Shop for spare parts

The TRUMPF E-Shop supports you with many helpful filters and functions as you search for, select and order your spare parts.

Quality: Details which make a difference

MyTRUMPF makes life so much easier

Order your TRUMPF spare parts conveniently and comfortably online in our E-Shop. And keep track of all your orders thanks to the MyTRUMPF order overview. Invoice downloads and shipment tracking included. Register now for free.

Our spare parts

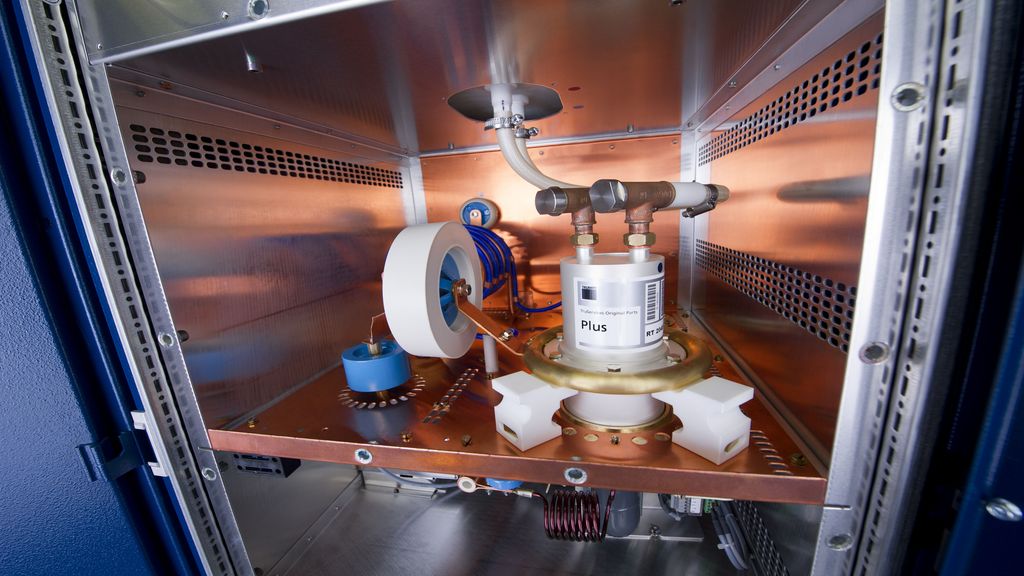

Original Power Tubes

The original Power Tube by TRUMPF is the heart of the generator of many CO2 laser processing machines . It ensures the maximum power for your laser. The compatible electrical parameters of Power Tube and generator ensure perfect interaction and top process reliability.

Every original Power Tube (transmission tube) from TRUMPF undergoes a stringent quality inspection. This guarantees a durable, high-quality product and a high degree of reliability.

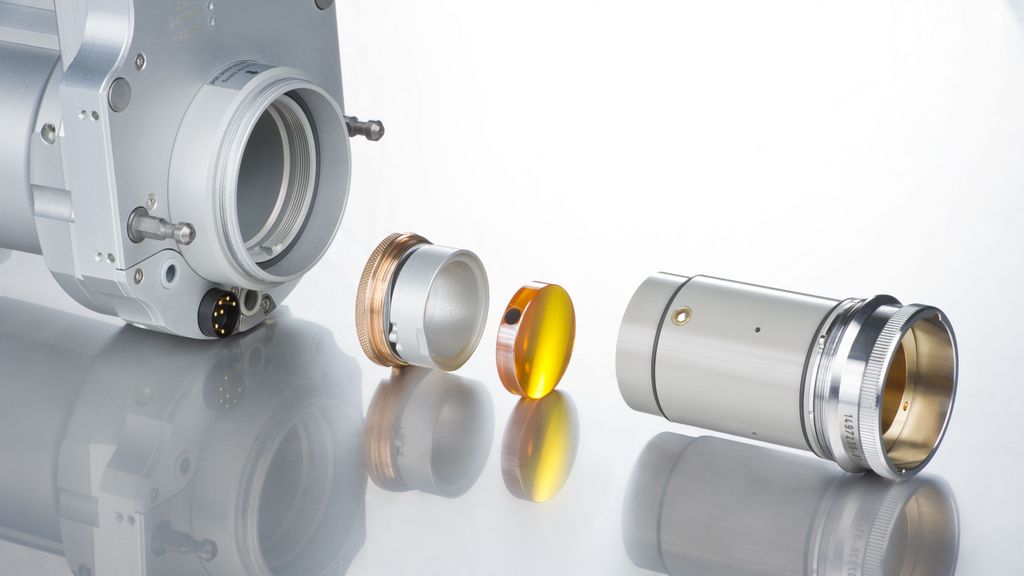

Original lenses

For an excellent cutting result from your laser machine, you simply cannot do without a high-quality lens in accordance with TRUMPF specifications. Careful material selection and stringent quality checks ensure that original lenses optimally focus the laser beam. This means you are provided with a precisely coordinated unit, from the machine to the sensor system, to the original lens. A perfect focal position and optimal cutting results are included. With the intelligent lens with RFID chip and the LensLine sensor system with condition check, genuine parts provide you with even more certainty. The correct installation and right focal length of the lens are always ensured. Cleaning cycles are also optimized through the interaction of LensLine and lens with RFID chip, saving up to 40% in non-productive times.

Variants

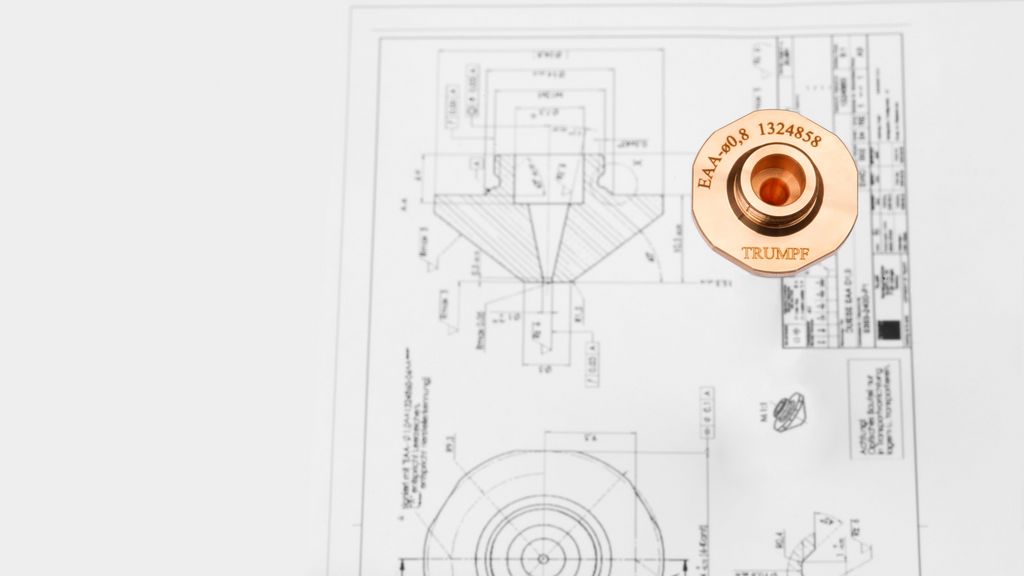

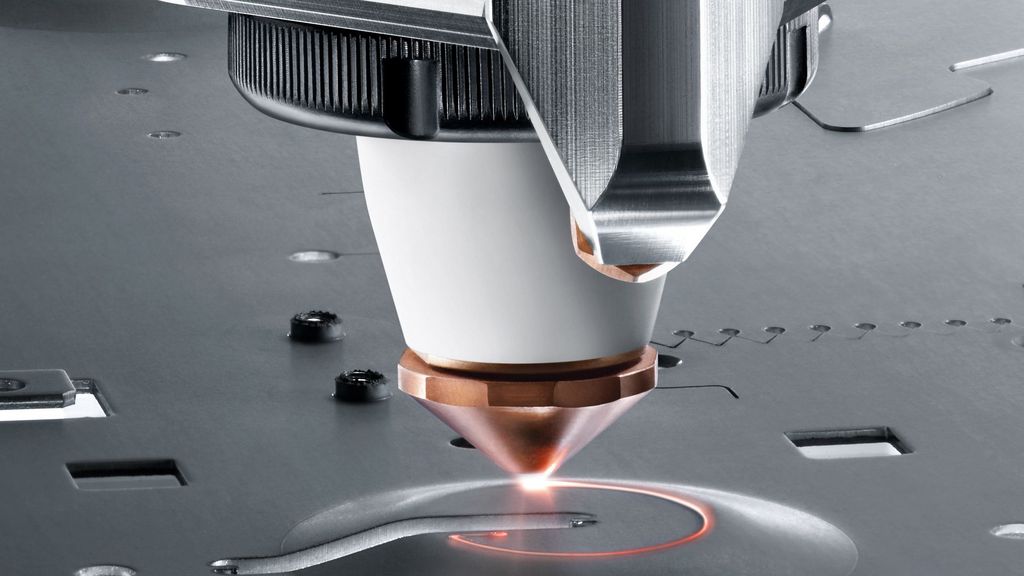

Original nozzles

An essential component: It is through the cutting nozzle that the laser beam and cutting gas meet the workpiece. Selecting the right nozzle is therefore crucial for part quality. Ensure you have the best cutting quality with the Original nozzles from TRUMPF. These are manufactured according to particularly stringent quality specifications. The precise surface of the nozzle created minimizes the amount of slag spatter, ensuring the distance regulation functions perfectly. A special material alloy optimally diverts heat and guarantees a long nozzle service life. You also benefit from the optimal nozzle geometry. Original nozzles guarantee flawless gas flow and minimized burr formation. They also only use as much cutting gas as is actually necessary.

Variants

Original BrightLine nozzle

Original CoolLine nozzle

Original nozzle holders

When they are optimally coordinated, nozzle holders, nozzles, and distance sensor systems ensure the best cutting process and ideal cutting results. This is why the highest quality standards are also applied for original nozzle holders during production. The ceramic and thread insert are bonded with the greatest precision. Once joined, they are inseparable and extremely robust. The resistant materials of the nozzle holder not only withstand extremely high temperatures but also ensure the electrical insulation in the high frequency range. This is necessary for the distance sensor system to always ensure the perfect distance between the sheet and the nozzle. By using the original, you therefore attain a constant focal position.

Variants

Weitere Düsenhalter in unserem E-Shop

Holen Sie sich für jede Schneidanwendung den richtigen Düsenhalter: Die komplette Übersicht unseres Portfolios an Original Düsenhaltern finden Sie in unserem Online Shop.

Genuine protective glasses

In solid-state laser machines and systems, the lens is protected against impurities by a protective glass. This serves as a pressure window for the cutting gas used and at the same time keeps spatter, smoke residue, and steam away from the lenses. Not every protective glass can withstand this pressure. Genuine protective glasses from TRUMPF are produced according to precise specifications to meet the wavelength of the laser light and the requirements of the cutting and welding processes, as well as the sensor system. A special coating as well as the use of particularly pure materials guarantee a low degree of reflection and absorption and prevent thermal changes to the glass. Genuine protective glasses form the foundation of reliable cutting and welding processes.

Example

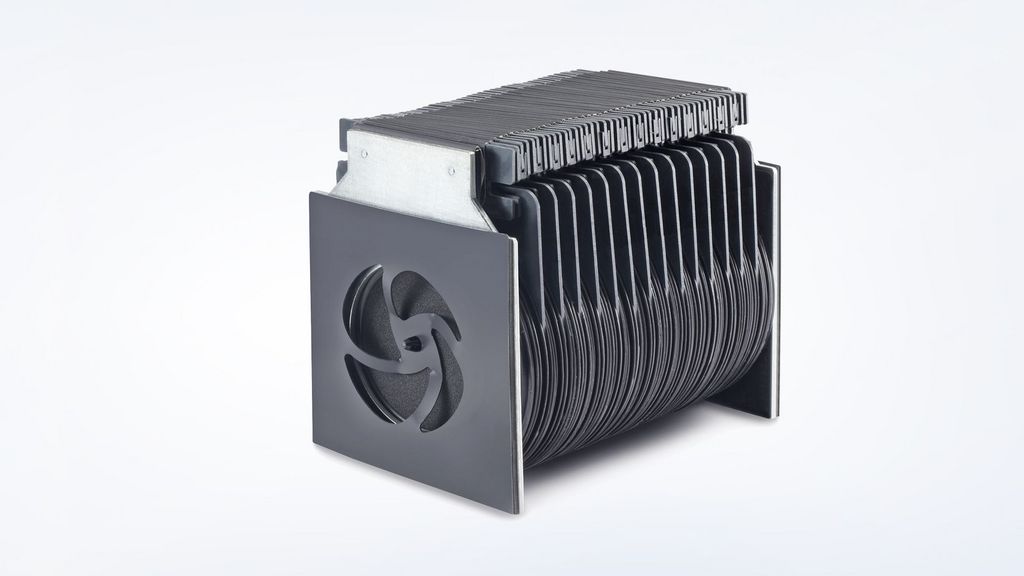

Original bellows

The axes of your machines and laser systems are covered with bellows to protect the sensitive beam guiding optics of your laser against dust and other particles. Only purified air or nitrogen is permitted inside the bellows, so that the laser beam is not absorbed or deflected. Due to the material quality, original bellows guarantee the best protection of the beam path, also ensuring the focal positioning on the workpiece. The bellows are subjected to extreme mechanical loads due to the high speeds of the cutting head and the entire motion unit, as well as the resulting pressure changes. This is why original bellows are made from particularly flexible, but also very stable and self-extinguishing plastic. Even in 3-shift operation, this means you can count on the long service life of your original bellows for the long term.

Variants

Original mirrors

Numerous optical elements shape, control, and focus the laser beam in your TRUMPF machine. So that you gain the best part quality at the end of the cutting process, we pour a great deal of knowledge into our high-quality original mirrors. Our engineers in Development and Production are constantly working on optimizing the original mirrors along the entire beam guidance. At TRUMPF diamond-cut optics are produced in a highly precise manufacturing method with specially developed fixtures and tools. Here, the engineers place great emphasis on producing the water-cooled mirrors under precisely defined conditions. The shape and dimensions of the original mirrors must be excellent.

Variants

Original filter elements

Original filter elements, tested by TRUMPF, function according to the principle of surface filtration. The dust is filtered directly at the surface and does not penetrate deeply due to the substrate made of permeable polyester fleece with a Teflon-coated surface. This means at least 99.95% of the particles can be filtered, even in the micrometer range – an absolute top value! Original filter elements ensure a constantly high filter performance for many years. During laser cutting, emissions are created from which your employees, the environment, and components of your machine or laser system should be protected. With our original filter elements, TRUMPF makes no compromise and even goes beyond the legal requirements. To ensure long-term protection, the cleaning intervals for your original filter elements are stored in your machine control.

Example

Original Easy Kits and filters

Perfect cooling is crucial for the availability of your machine. In order to lengthen the service life of the resonator and optics, you should typically service the cooling circuit once a year, thereby removing impurities and particles from the cooling water. With the Easy Filter, you can recycle the used cooling water in simple steps – parallel to production. Together with the original Easy Kit, you can clean your cooling circuit sustainably and optimally protect your components. TRUMPF offers the right original Easy Filter and original Easy Kit for every laser machine or laser system type. This provides you with all of the components required for the cleaning cycle, such as cleaning biocide and corrosion protection, together in a coordinated set – there is no need for complicated metering and storage. It couldn't be more simple.

The original filter cartridges are comprised of a covered fiber, whose fleece layers are fused securely to each other in a special process. This manufacturing process provides you with benefits. This outstanding strength enables the original filter cartridge to withstand maximum pressure differences without losing fibers. This means your filter components and water cooling channels are constantly kept free of loose fibers. The original filter cartridge ensures your laser/laser system or machine is ideally cooled for the long term.