Semi-automatic panel bender

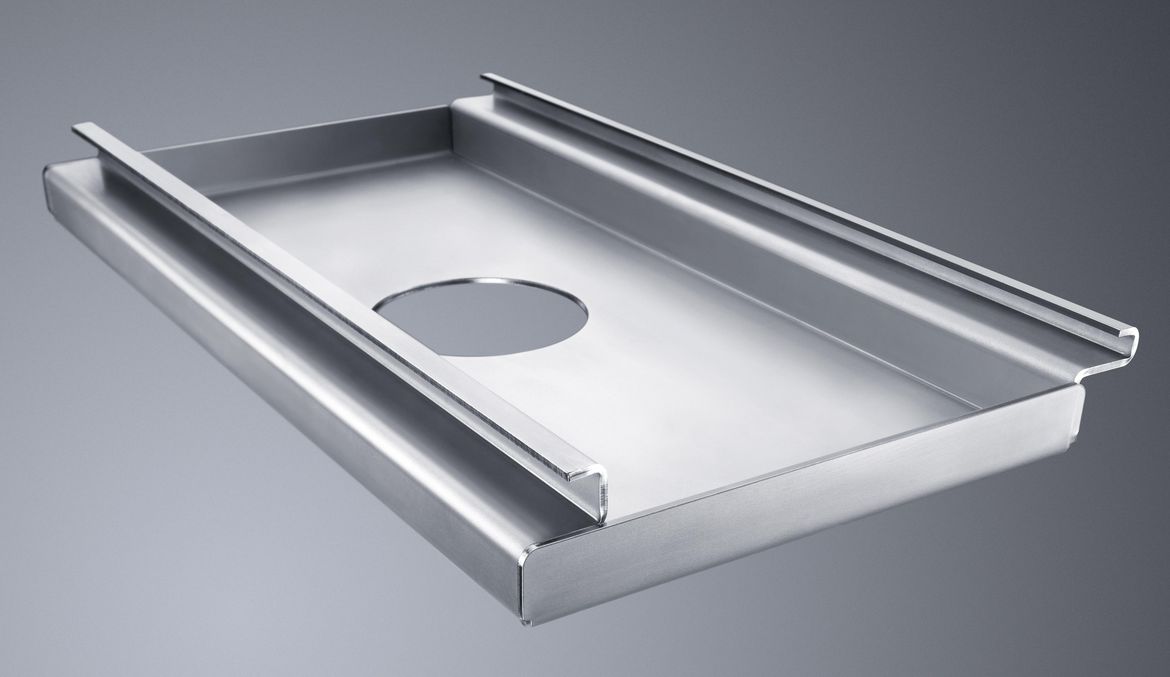

The TruBend Center 5030 sets the standard when it comes to flexibility during panel bending. Discover what is arguably the widest range of parts in this machinery category with the semi-automatic TruBend Center 5030. Go far beyond traditional panel bending capabilities, process complex workpieces quickly and with flexibility. Produce components for an array of industrial purposes and applications, from delicate shrouds up to large-scale trays.

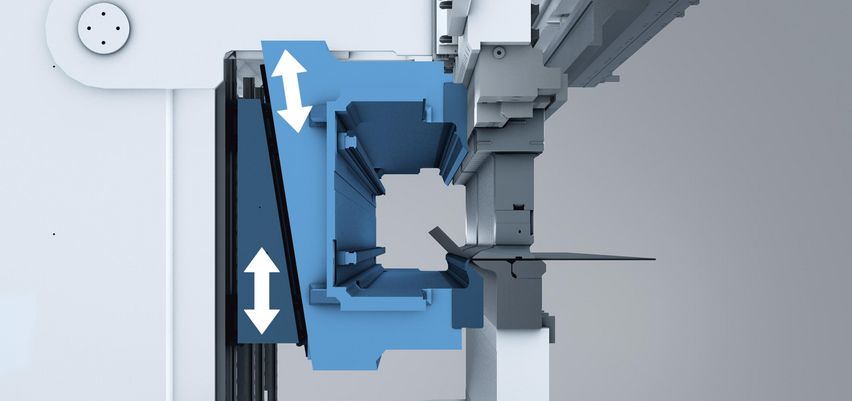

The 2-axis part manipulator positions the sheet metal and even enables negative bends.

Simple offline programming with TecZone Fold.

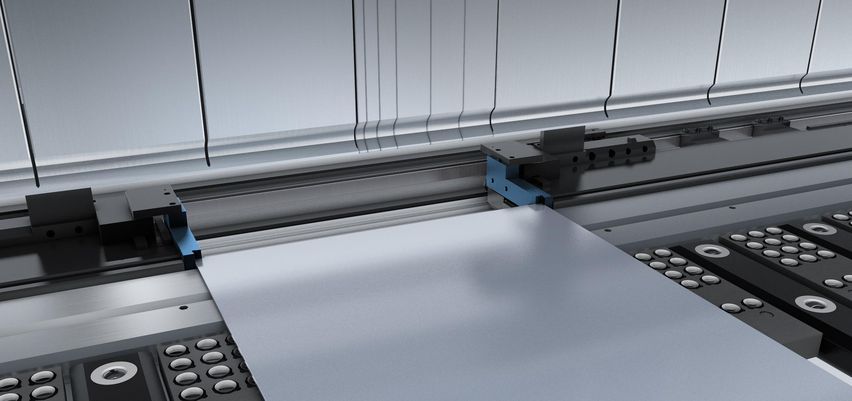

First part, perfect part – with the ACB laser.

Set up the right upper blank holder tools automatically with the integrated tool changer ToolMaster Bend.

Various gripper systems help to hold the components.

The on-demand servo drive works quickly, quietly, and in an energy-efficient way.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.