Minimum setup times when loading

Minimize your setup times with the LoadMaster Tube by TRUMPF. The bundle space holds up to four tons of unprocessed material, which is fed by the loading unit following a check. For the larger version of the machine, the capacity is even greater. The machine software compares the geometry of the tubes with the stored data, ensuring trouble-free operation. The gripper system transfers the tubes, which have been measured automatically, to the machine.

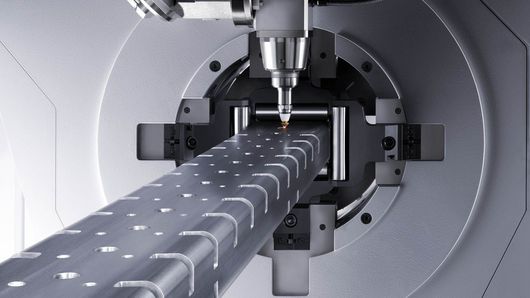

Smart Profile Detection detects the angular position and orientation of the tube and automatically positions the clamping system.

Depending on the model, with the LoadMaster Tube, you can load tubes up to 30 ft.

You can load small series using the conveyor system or manually.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.