*depending on the options selected

Automation happens just that fast

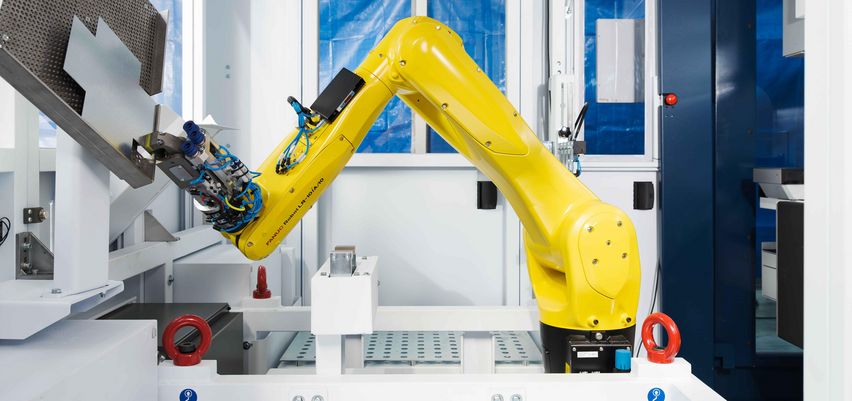

The Flex Cell bending automation transforms your manual TruBend 7050 into the fastest bending cell from TRUMPF. When urgent orders are due, you can use Flex Cell to scale your production capacity for simple parts in no time at all. And without the need for additional staff at the machine. This relieves your team and allows you to run autonomous shifts. Simply connect the mobile robot cell to your bending machine. This gives you a fully automated bending cell with generously sized raw material storage and a compact installation area.

The fastest bending cell for simple components from TRUMPF

Double loading capacity enables autonomous runtime up to 42 hours.

Automated bending power in the smallest of spaces (< 10 m²).

Produce challenging components manually, simple components automatically. The Flex Cell is ready for production in just a few minutes.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.