Micro-materials processing: maximum productivity

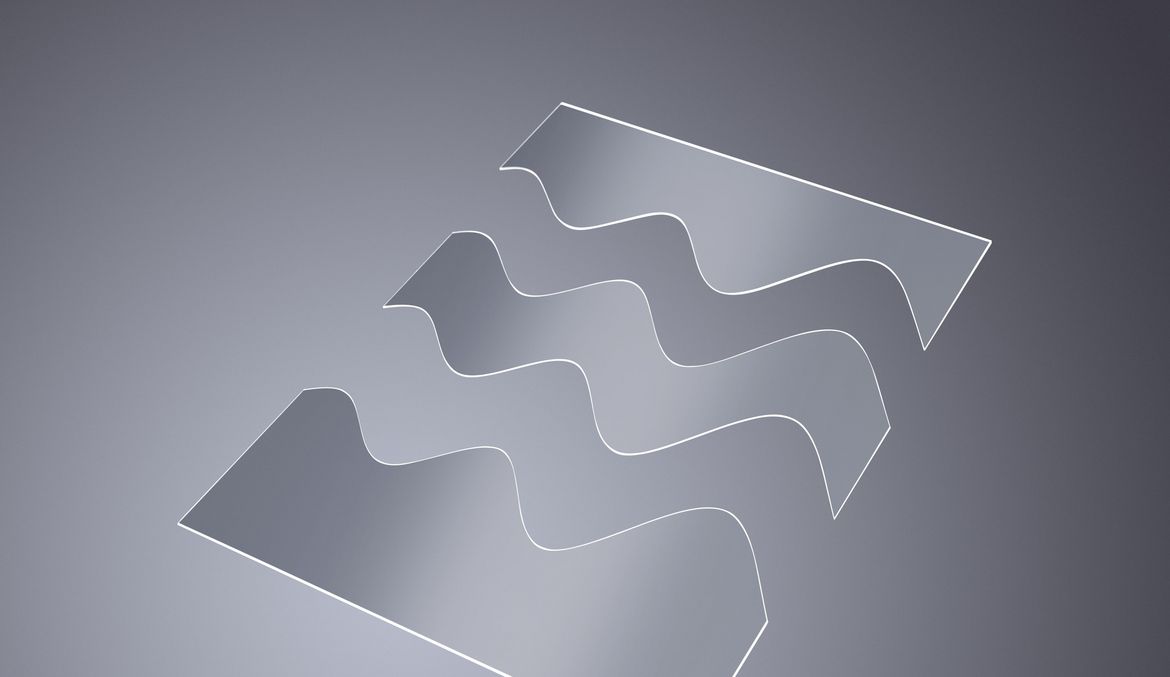

The short and ultrashort pulse lasers from TRUMPF enable microprocessing with an optimal combination of quality, productivity, and profitability, with no limits in terms of industrial suitability. The particular pulse and power stability is achieved through the separation of pulse generation and pulse output. The patented control ensures monitoring of each individual pulse, and keeps the power and pulse energy at exactly the right level required for the application. The picosecond lasers of the TruMicro Series 5000 impress with their high pulse energy of up to 500 μJ. All of this together with excellent beam quality and average powers of up to 150 W. This ensures maximum productivity in micro-materials processing. They vaporize virtually every material so quickly that heat influence cannot be detected. They are therefore, ideal for processing semiconductor materials, metals, dielectrics, plastics, and glasses.

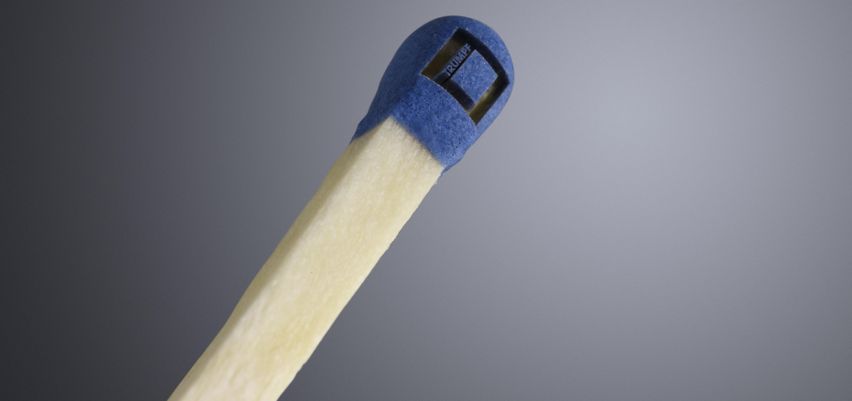

The ultrafast power modulator keeps power and pulse energy at an exact level.

Process temperature-sensitive materials without significant heat input.

TruMicro lasers can be integrated easily and are compatible with all common interfaces.

100% of the average power even in individual pulses as a result of regenerative disk technology

The lasers, which are based on the successful TruMicro Series 5000, are designed for your everyday production tasks.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.