The perfect laser line for every application – due to the TRUMPF line-focusing optics

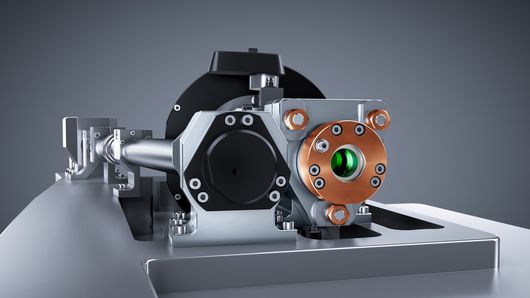

Extremely narrow, extremely long, extremely even: Line-focusing optics from TRUMPF form a thin line from the round laser beam, and distribute the power intensity evenly over the entire line profile. If several line-focusing optics are combined in a modular manner, lasers with an infrared wavelength can even process large areas of several square meters. During the laser lift-off process used in the manufacture of modern OLED displays, the line-focusing optics focus the laser beam with ultraviolet wavelength in a line shape from behind through the glass substrate. TRUMPF line-focusing optics can be flexibly combined with the pulsed and continuous wave solid-state lasers from TRUMPF, and can be adapted precisely to spatial and application-specific requirements.

The power intensity is distributed evenly over the entire line profile with fluctuations of less than 10%.

The line-focusing optics can be easily integrated in industrial production lines, and can be individually combined for every application.

With a width which is smaller than a human hair, the line-focusing optics focus the laser beam onto the workpiece with a high irradiance.

IR line-focusing optics can easily be combined in a modular manner so that laser lines of several meters can be created.

Architectural glass

Together with Saint-Gobain and Manz, TRUMPF has developed a patented technology for the surface treatment ("rapid thermal annealing") of industrially manufactured plate glass. In this so-called ACTILAZ™ process, a silver layer which is just a few micrometers thick is briefly heated up on the glass substrate. Twelve TRUMPF TruDisk disk lasers with an infrared wavelength connected in parallel, as well as eight IR line-focusing optics combined in a modular manner generate a laser line which is 3.3 m long and thinner than 100 µm over the entire width. The intensity of the laser radiation varies by less than 10% in the process.

In the event of an error, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives. This enables maximum availability for you.

Processing optics and fiber optic cables can be cooled easily and conveniently using the laser cooling water. Separate cooling is therefore, not necessary.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.