Reliable thanks to 3D information

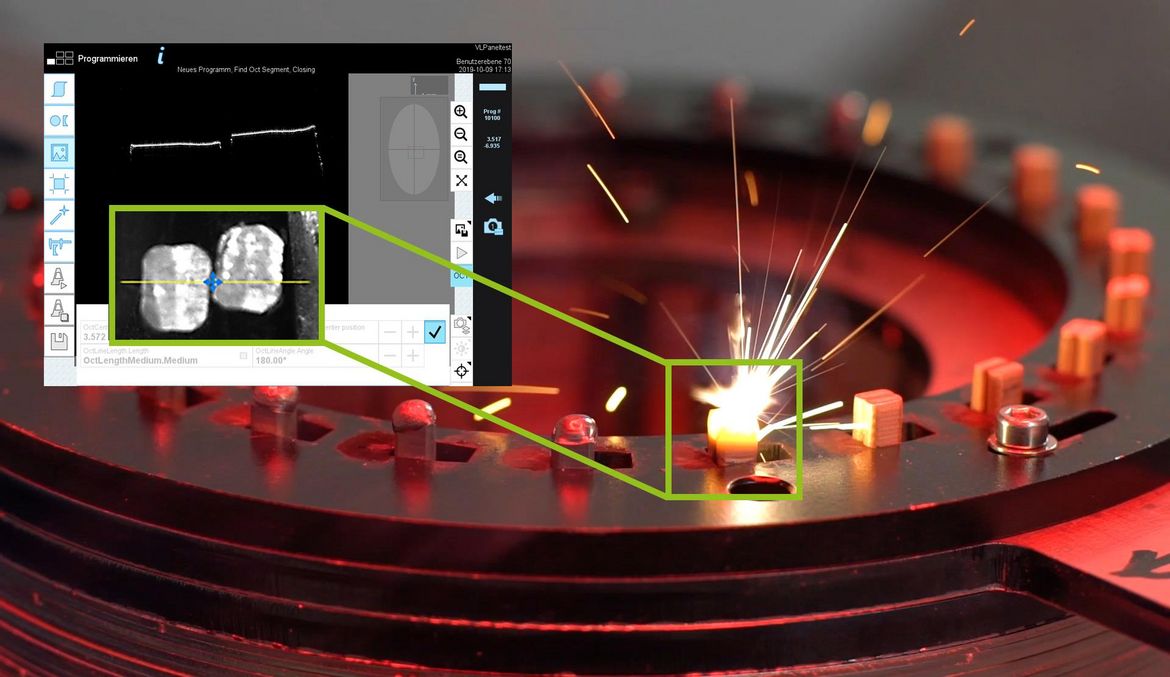

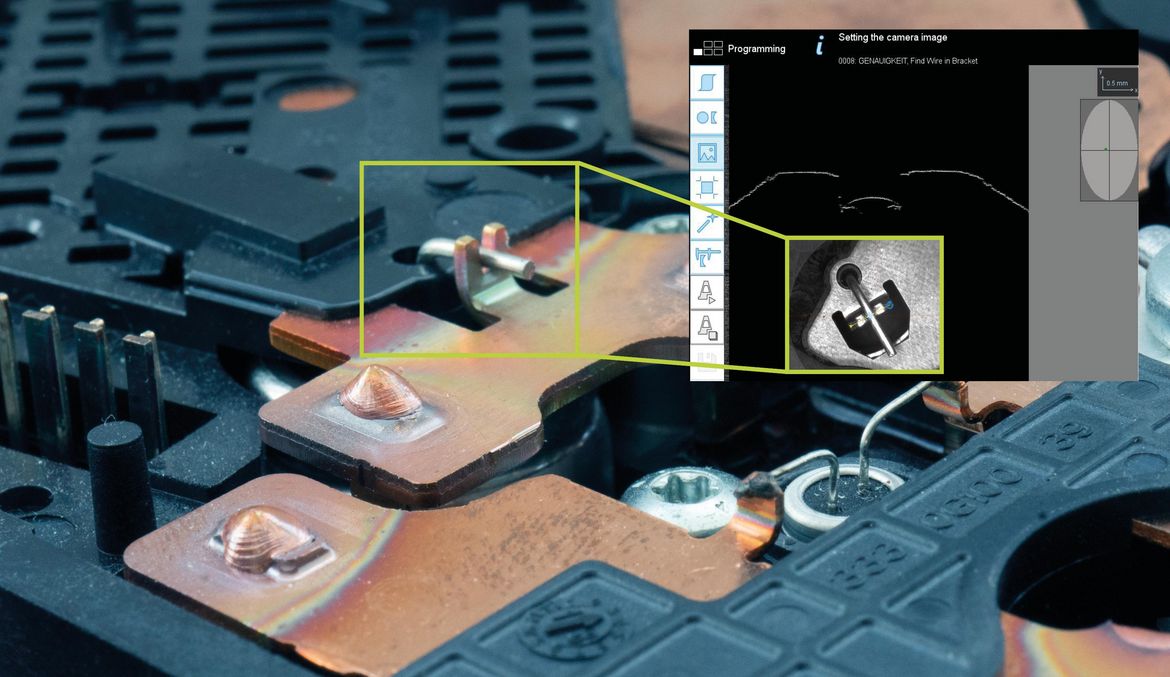

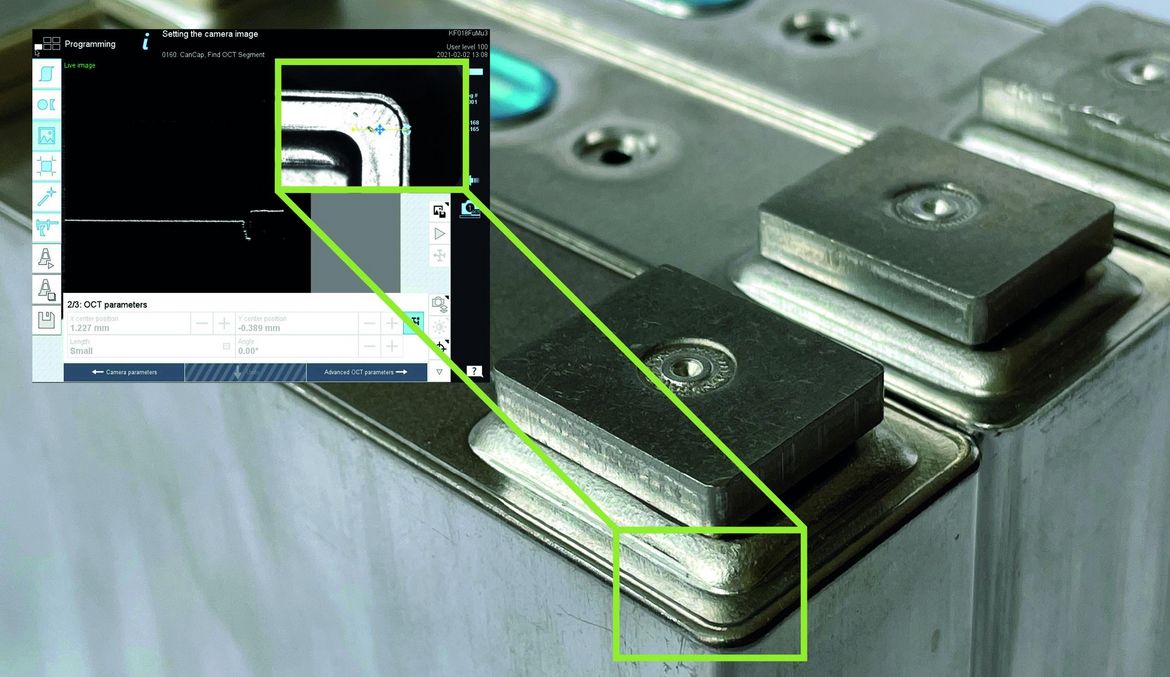

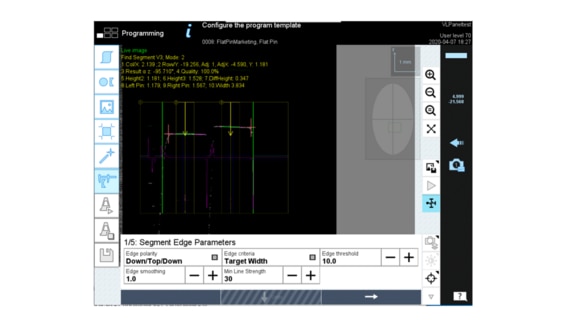

VisionLine OCT Detect combines the world of incident light image processing with optical coherence tomography, thereby detecting characteristics in three dimensions. The OCT sensor scans the component coaxially to the processing laser and as such, is operating independently of the respective lighting and clamping situation. The 3D information created in this way can be used to position and check the part characteristics, such as the height difference of two components.

You can reliably detect beforehand whether a pair of hairpins are the same height.

The OCT beam guidance is plotted directly in the camera image.

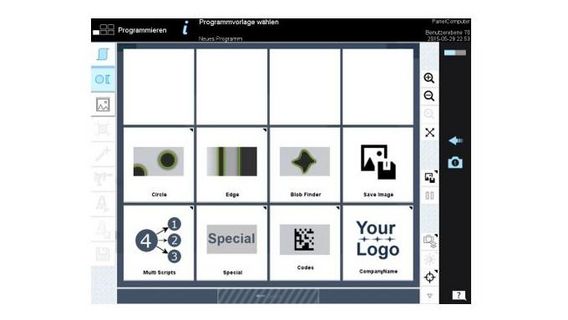

The TRUMPF expert team develops algorithms tailored to your component.

Additional QDS-2 (Quality Data Storage) software is used to transfer sensor data synchronously to the process.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.