Cost-efficient welding expert

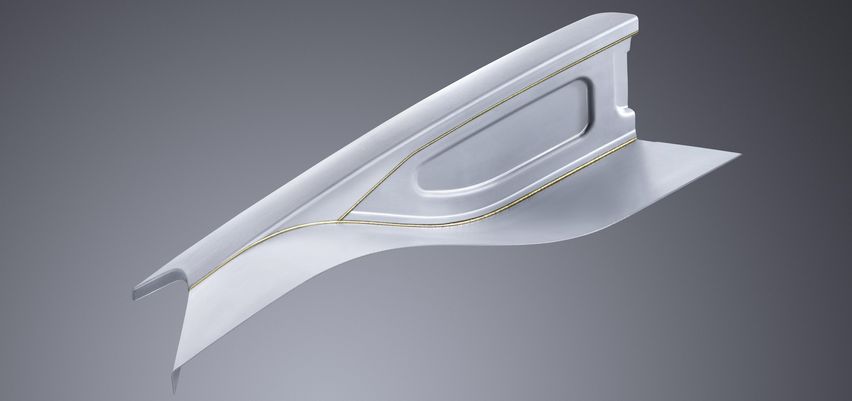

The extremely energy-efficient TruDiode diode lasers impress through optimal results and low operating costs. Regardless of deep welding, heat conduction welding and laser metal deposition, soldering, or plastic welding: The lasers deliver excellent seam qualities. With its modular, space-saving design, you can integrate the TruDiode easily in your production systems. You can supply up to four work stations with flexibility within the laser network.

Stable processes through integrated, active laser power control ensure reproducible results.

The TruDiode saves resources with its high degree of efficiency and intelligent energy management.

The welding expert joins plastics or metals, both with and without auxiliary materials.

With its direct diode principle, the TruDiode impresses with a footprint that is considerably less than 11 ft2.

Long service life through passively cooled diode modules

|

TruDiode 151

|

TruDiode 301

|

|

|---|---|---|

| Laser parameters | ||

| Laser power on the workpiece | 150 W | 300 W |

| Typical power constancy at rated power | ± 1 % | ± 1 % |

| Continuously adjustable power range | 3 W - 150 W | 6 W - 300 W |

| Beam quality | 8 mm▪mrad | 8 mm▪mrad |

| Numerical aperture | 0.12 | 0.12 |

| Wavelength | 920 nm - 970 nm | 920 nm - 1050 nm |

| Minimum laser light cable diameter | 150 μm | 150 μm |

| Structural design | ||

| Dimensions, 19" version (W x H x D) | 483 mm x 495 mm x 513 mm | 483 mm x 495 mm x 513 mm |

| Maximum number of laser light cables | 2 | 2 |

| Installation | ||

| Ambient temperature | 5 °C - 40 °C | 5 °C - 40 °C |

The technical data of all product versions as a download.

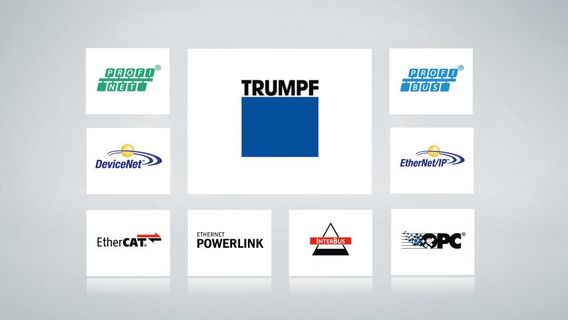

TruControl

TruControl is the control software for your TRUMPF solid-state laser – for quick and simple operation. You can program pulse shapes individually to match your application. The laser power is controlled in real time to ensure maximum reproducibility of your process results. In order to retrace important quality data of your produced parts even years later, the optional DataStore software module records all data relevant to quality. If external controls are present, TruControl will communicate with them via all standard interfaces. Inputs are made via the touchscreen of the operating panel or via a panel PC. You can integrate your laser into the network via Ethernet and connect multiple PCs.

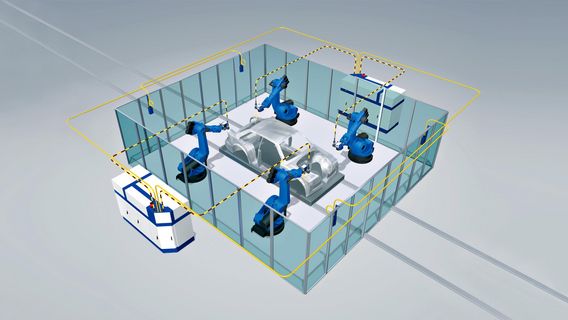

With TRUMPF you have the option to adapt your solid-state laser with flexibility to your installation and operating situation. This applies, for example, to all beam guidance components and the control. You also have several options for the cooling water supply. Interfaces for different optics are provided right from the start. To save costs, your beam source can supply several work stations at the same time. The TRUMPF Remote Service helps ensure your system remains available, anywhere and at any time.

Regardless of the age of the laser device or the ambient conditions, the laser power is maintained at a specified value (with a typical deviation of ±1%). This ensures that the process results are reproduced across the entire service life of the laser.

Processing optics and fiber optic cables can be cooled easily and conveniently using the laser cooling water. Separate cooling is therefore, not necessary.

In the event of malfunctions, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the error can be remedied in this way, or the laser configuration can be modified to enable you to continue manufacturing until the spare part arrives. This enables maximum availability for you.

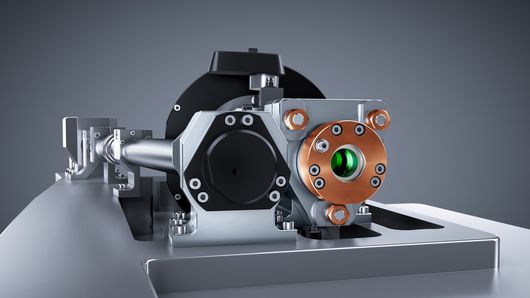

Interfaces are key for the integration of a TruDiode laser in your machine or production line. The solid-state lasers from TRUMPF offer interfaces to all common fieldbus systems. Also available: real-time interface, parallel digital I/O, interface for process sensor systems, OPC UA software interface, analog input card, interface for intelligent TRUMPF optics, e.g. CFO or PFO.

The TruDiode has interfaces to control intelligent TRUMPF optics, such as monitored CFO focusing optics or PFO scanner optics. You can program the processing optics easily via the laser control system, and there is no need for an additional PC or control. Recorded data and associated limit values including warnings and error messages can be visualized in the TruControl laser control system.

With the laser network, you can connect one or more TruDiode lasers with up to two or four work stations in each case. In the process, your laser either splits its power to multiple stations, or it supplies them by turns with full power. This increases the capacity utilization for the laser, reduces the part costs, and even enables you to combine different applications.

The TRUMPF sensor systems mean that your production will always be both effective and cost-efficient. The sensor products VisionLine, CalibrationLine or integrated pyrometers ensure stable processes by monitoring all the procedures in laser production and make a significant contribution towards your process reliability. Processing continues unimpeded during the measurement – no interruptions are required, saving you valuable production time.

Image processing

TRUMPF VisionLine image processing detects features on the components and ensures that welding is always in the correct location.

Calibration tool

The TRUMPF CalibrationLine tool checks and corrects the focal position and laser power on the workpiece at regular, individually definable intervals.

Temperature control

The TRUMPF temperature control ensures high-quality visual results for plastic welding.

Melt travel monitor

The TRUMPF melt travel monitor monitors the lowering of the component during the laser transmission welding of plastics.

Lasers and laser systems – with us, the perfect pair. All beam sources are optimally attuned to the requirements of the TRUMPF laser systems. You can choose between numerous versions and options, resulting in a system which is precisely tailored to your task. It is, of course, also possible to integrate our lasers directly into your production lines.

TRUMPF offers you all the components you need for beam guidance from the laser to the workpiece. This also applies for various focusing optics which have proven themselves to be precise and reliable over many years of industrial use. The optics can be easily integrated – both in stand-alone processing stations as well as in complete production lines. The TRUMPF processing optics are perfectly tailored to the TRUMPF lasers and are available for all wavelengths.

Focusing optics

Regardless of whether you are welding, cutting, ablating, heat treating, or drilling, you can count on high-quality process results with robust focusing optics from TRUMPF.

Programmable focusing optics

The ideal optics for remote processing

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.